Performance Verification

4–2

AM700 Audio Measurement Set Service Manual

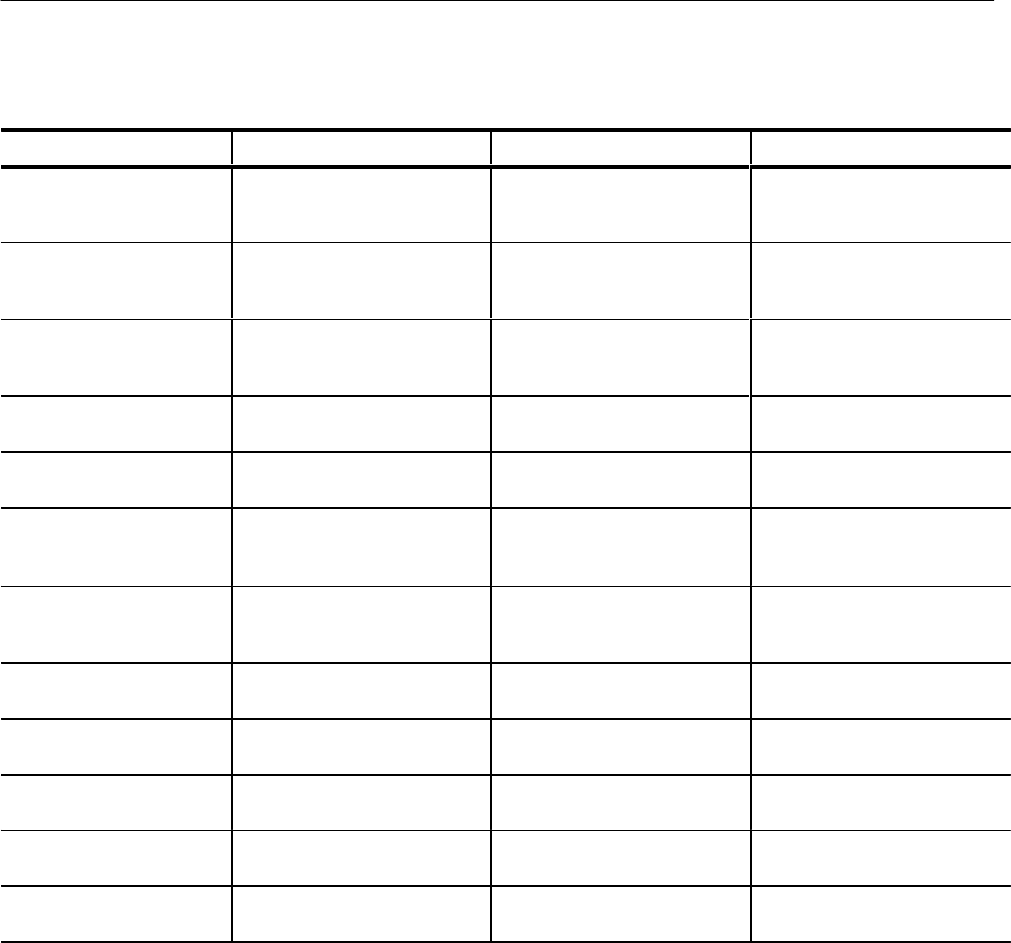

Table 4–1: Required test equipment (cont.)

Equipment required ExamplePurposeMinimum specification

Digital Audio Measurement

Set

Tektronix AM700 Provide digital audio test signals

and measure digital audio test

signals

Tektronix AM700 Audio Measure-

ment Set

Personal Computer PC-DOS or MS-DOS 3.0 or

higher, 386, 3.5 inch disk drive.

Serial RS-232 port.

Provide for remote control of the

AM700.

Serial printer with RS–232C

interconnection cable

24-pin dot matrix with RS-232C

serial interface

Check RS–232C operation serial

printer output

Epson LQ series serial printer or

Hewlett-Packard LaserJet with

serial input.

GPIB controller with stan-

dard GPIB cable

Check GPIB remote operation Guru II+ Tektronix product

number S3FG100

Interconnection audio cables

for test equipment.

XLR to XLR Signal interconnection Supplied with test equipment

Impedance Transformer 110 W to 75 W impedance

matching

Match AES ref out to 75 W

system

Canare 110 W to 75 W matching

transformer. Part number BCJ–

XJ–TRA

Interconnection Cables See Figure 4–1 Connect AM700 inputs and

outputs to various test equip-

ment.

Customer fabricated. See Figure

4–1 for diagram.

Audio Cables (2) Standard XLR female to XLR

male

Signal Interconnection Customer provided

Attenuator 10X 75 W BNC Signal attenuation for digital

signal connection to oscilloscope

Tektronix part number

011-0061-00

Termination Feed through 75 W BNC Signal termination for digital

signal connection to oscilloscope

Tektronix part number

011-0103-02

Termination 75 W BNC, 0.025% Signal termination Tektronix part number

011-0102-01

BNC T connector Signal interconnection Tektronix part number

103-0030-00

1

A Tegam TM500 or TM5000 power supply is required to power the plug-in module.

Fabricated Test Cables

Several of the test cables to make the connections from the XLR connectors of

the AM700 to the different connectors of various test equipment are fabricated

specifically the AM700 verification and adjustment procedures. If the verifica-

tion procedures you want to perform call for one of these cables, you must

fabricate it or a similar cable to make the connections. Figure provides a guide

for use in making the special connector cables.