Configuration and Use Manual 207

Diagnostics and Troubleshooting

Diagnostics and Troubleshooting Specifications – Model 3350/3700Specifications – Model 3300/3500Measurement Performance

When the cursor is positioned on Current, you can use the RESET button to set a new start time for

the recorded minimum and maximum values.

When the cursor is positioned on Factory, you can use the

SAVE button to overwrite the data in the

factory fingerprint with the current fingerprint data.

Note: Due to the continuous updating, the meter fingerprinting feature can have a negative effect on

other sensor-transmitter communications. Do not open the meter fingerprinting window unless you

plan to use it, and be sure to close it when you no longer need it.

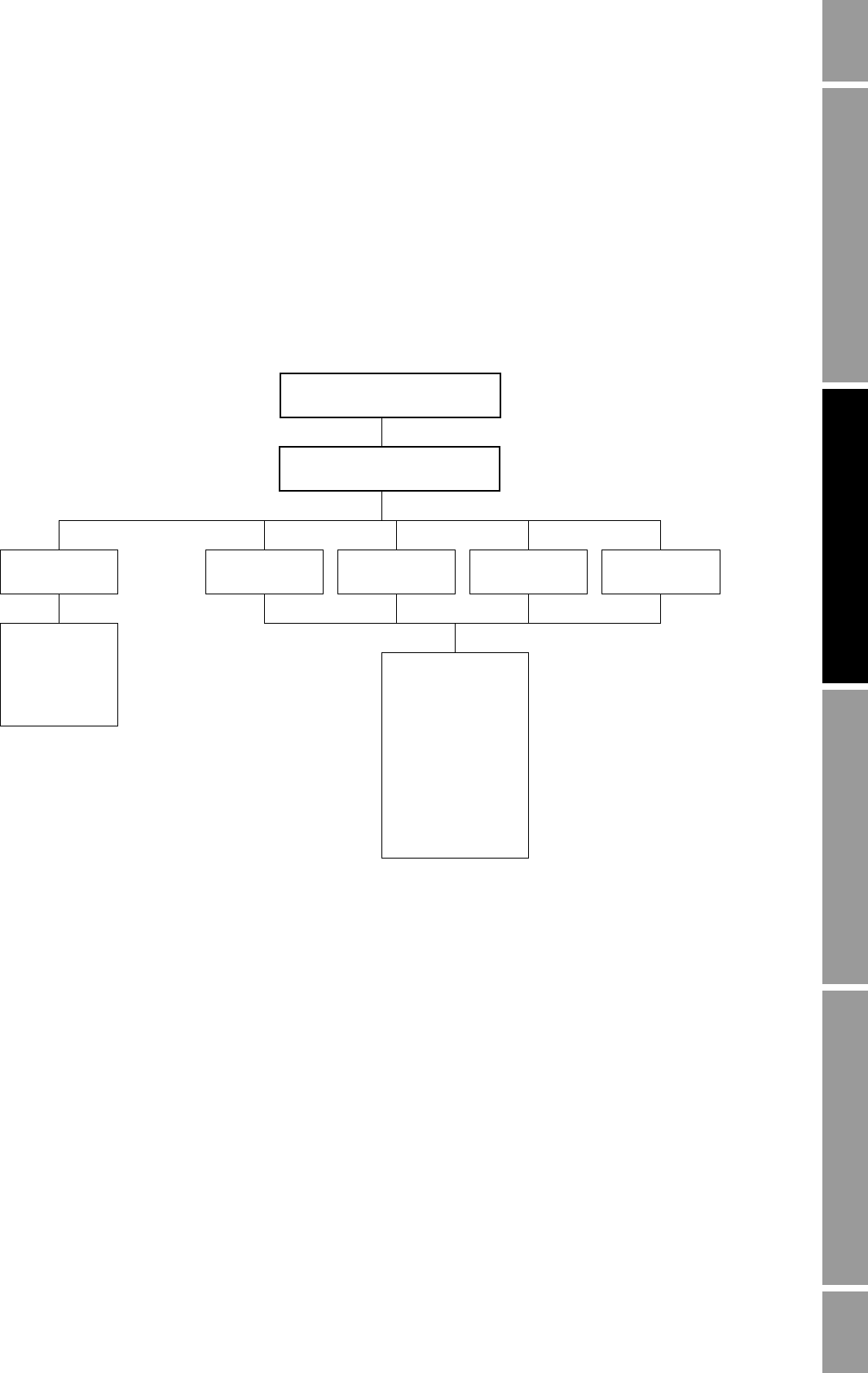

Figure 22-1 Meter fingerprinting menu

22.4 Sensor simulation mode

Note: Sensor simulation mode is available only on systems with the enhanced core processor.

Sensor simulation allows you to simulate process data for mass flow, temperature, and density. Sensor

simulation mode has several uses:

• It can help determine if a problem is located in the transmitter or elsewhere in the system. For

example, signal oscillation or noise is a common occurrence. The source could be the PLC, the

meter, improper grounding, or a number of other factors. By using sensor simulation to output

a flat signal, you can determine the point at which the noise is introduced.

• It can be used to analyze system response or to tune the loop.

Maintenance

• Mass flow rate

• Volume flow rate

• Density

• Temperature

• Case temperature

•Live zero

• Tube frequency

• Drive gain

• Left pickoff

• Right pickoff

• Board temperature

• Input voltage

Meter Fingerprinting

SI

English

Units Current Factory Installation Last zero