6/08 ST 3000 Release 300 and SFC Model STS103 User’s Manual 41

4.3 Piping ST 3000 Transmitter, Continued

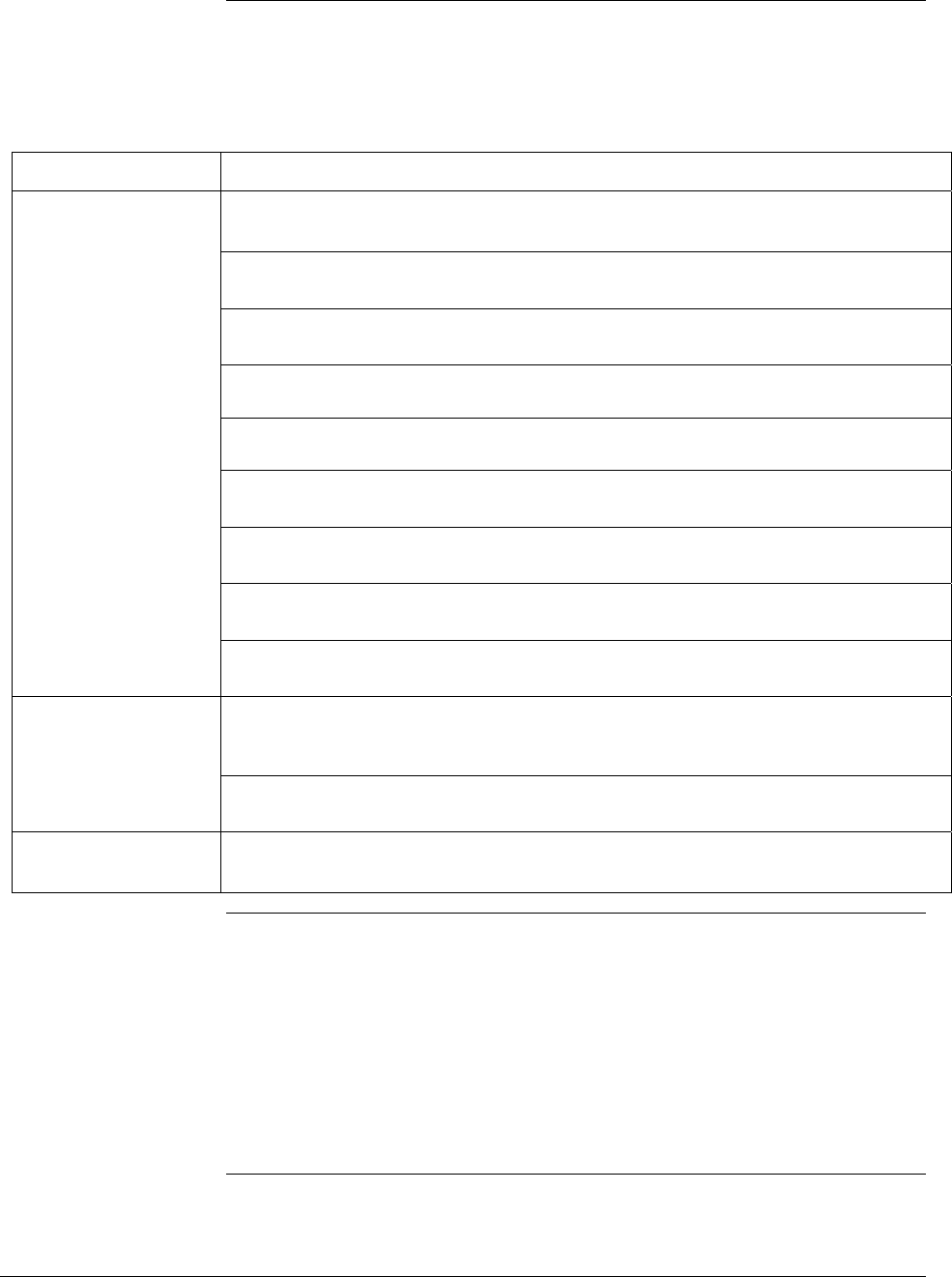

Flange descriptions

Table 14 describes the available flange connections for flange mounted

liquid level transmitters.

Table 14 Flange Description

Transmitter Type Description

Flush or Extended

Diaphragm

2-inch 150# serrated–face flange with 4 holes 19 mm (3/4 in) diameter on 120.7

mm (4.75 in) diameter bolt circle and an outside diameter of 150 mm (5.91 in).

2-inch 150# serrated–face flange with 8 holes 19 mm (3/4 in) diameter on 127 mm

(5.00 in) diameter bolt circle and an outside diameter of 165 mm (6.50 in).

3-inch 150# serrated–face flange with 4 holes 19 mm (3/4 in) diameter on 152.4

mm (6.00 in) diameter bolt circle and an outside diameter of 190 mm (7.48 in).

3-inch 300# serrated–face flange with 8 holes 22.2 mm (7/8 in) diameter on 168.3

mm (6.62 in) diameter bolt circle and an outside diameter of 210 mm (8.27 in).

4-inch 150# serrated–face flange with 4 holes 19 mm (3/4 in) diameter on 190.5

mm (7.50 in) diameter bolt circle and an outside diameter of 230 mm (9.05 in).

4-inch 300# serrated–face flange with 8 holes 22.2 mm (7/8 in) diameter on 255

mm (10.04 in) diameter bolt circle and an outside diameter of 200 mm (7.87 in).

DN 50 PN 40 serrated–face flange with 4 holes 18 mm (0.71 in) diameter on 125

mm (4.92 in) diameter bolt circle and an outside diameter of 165 mm (6.50 in).

DN 80 PN 40 serrated–face flange with 8 holes 18 mm (0.71 in) diameter on 160

mm (6.30 in) diameter bolt circle and an outside diameter of 200 mm (7.87 in).

DN 100 PN 40 serrated–face flange with 8 holes 22 mm (0.87 in) diameter on 190

mm (7.48 in) diameter bolt circle and an outside diameter of 235 mm (9.25 in).

Pseudo Flange Head

2-inch, 150 lbs serrated-face flange with 4 holes 15.9 mm (5/8 in) diameter on

120.6 mm (4-3/4 in) diameter bolt circle and an outside diameter of 152.4 mm (6

in).

3-inch, 150 lbs serrated-face flange with 4 holes 19 mm (3/4 in) diameter on 152

mm (6 in) diameter bolt circle and an outside diameter of 190 mm (7-1/2 in).

Flush Mount

Gauge STG93P

25.4 mm (1” pipe mount) (316L SS standard option.)

General piping

guidelines

• When measuring fluids containing suspended solids, install

permanent valves at regular intervals to blow-down piping.

• Blow-down all lines on new installations with compressed air or

steam and flush them with process fluids (where possible) before

connecting these lines to the transmitter’s meter body.

• Be sure all the valves in the blow-down lines are closed tight after the

initial blow-down procedure and each maintenance procedure after

that.

Continued on next page