6/08 ST 3000 Release 300 and SFC Model STS103 User’s Manual 171

9.3 Inspecting and Cleaning Barrier Diaphragms

Background

Depending on the characteristics of the process medium being

measured, sediment or other foreign particles may collect in the process

head cavity/chamber and cause faulty measurement. In addition, the

barrier diaphragm or diaphragms in the transmitter’s meter body may

become coated with a residue from the process medium. The latter is

also true for external diaphragms on flange mount and remote seal type

transmitters.

In most cases, you can readily remove the process head or heads from

the transmitter’s meter body to clean the process head cavity and inspect

the barrier diaphragm or diaphragms. For flange mount and remote seal

diaphragms, you may only need to run a purge line in the tank to rinse

off the face of the diaphragm.

Procedure

The procedure in Table 53 outlines the general steps for inspecting and

cleaning barrier diaphragms. You may have to modify the steps to meet

your particular process or transmitter model requirements.

Table 53 Inspecting and Cleaning Barrier Diaphragms

Step Action

1

Close all valves and isolate transmitter from process. Open vent in

process head to drain fluid from transmitter’s meter body, if required.

ATTENTION

We recommend that you remove the transmitter

from service and move it to a clean area before taking it apart.

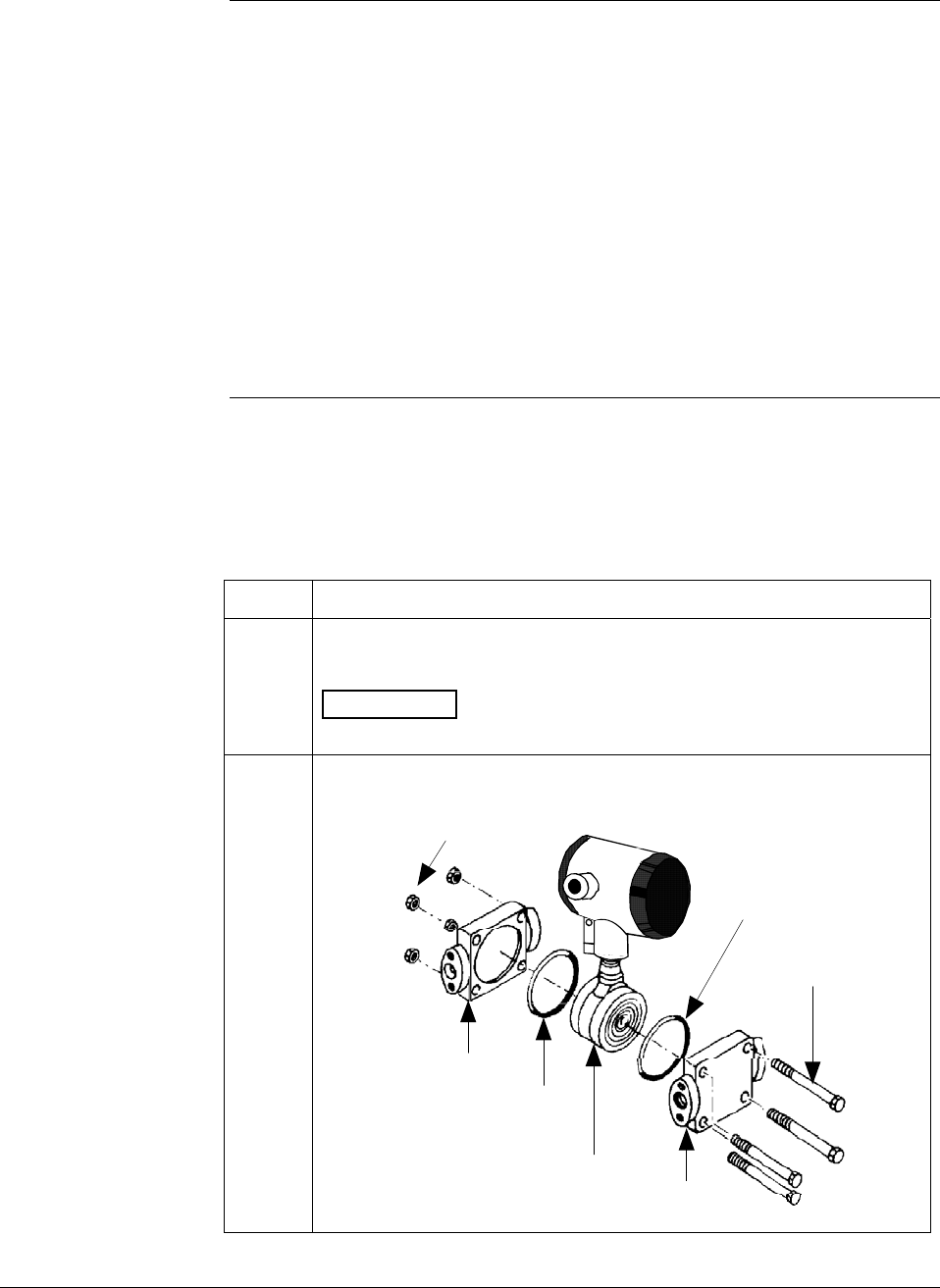

2

Remove nuts from bolts that hold process head or heads to meter

body. Remove process heads and bolts.

Nuts

Process

head

O-ring

Center

section

Process

head

O-ring

Bolts

Continued on next page