ST 3000 Release 300 and SFC Model STS103 User’s Manual 6/08

172

9.3 Inspecting and Cleaning Barrier Diaphragms, Continued

Procedure, continued

Table 53 Inspecting and Cleaning Barrier Diaphragms, continued

Step Action

3

Remove O-ring and clean interior of process head using soft bristle

brush and suitable solvent.

4

Inspect barrier diaphragm for any signs of deterioration or corrosion.

Look for possible residue and clean if necessary.

NOTE: If diaphragm is dented, has distorted convolutions or radial

wrinkles, performance may be affected. Contact TAC for

assistance.

5

Replace O-ring.

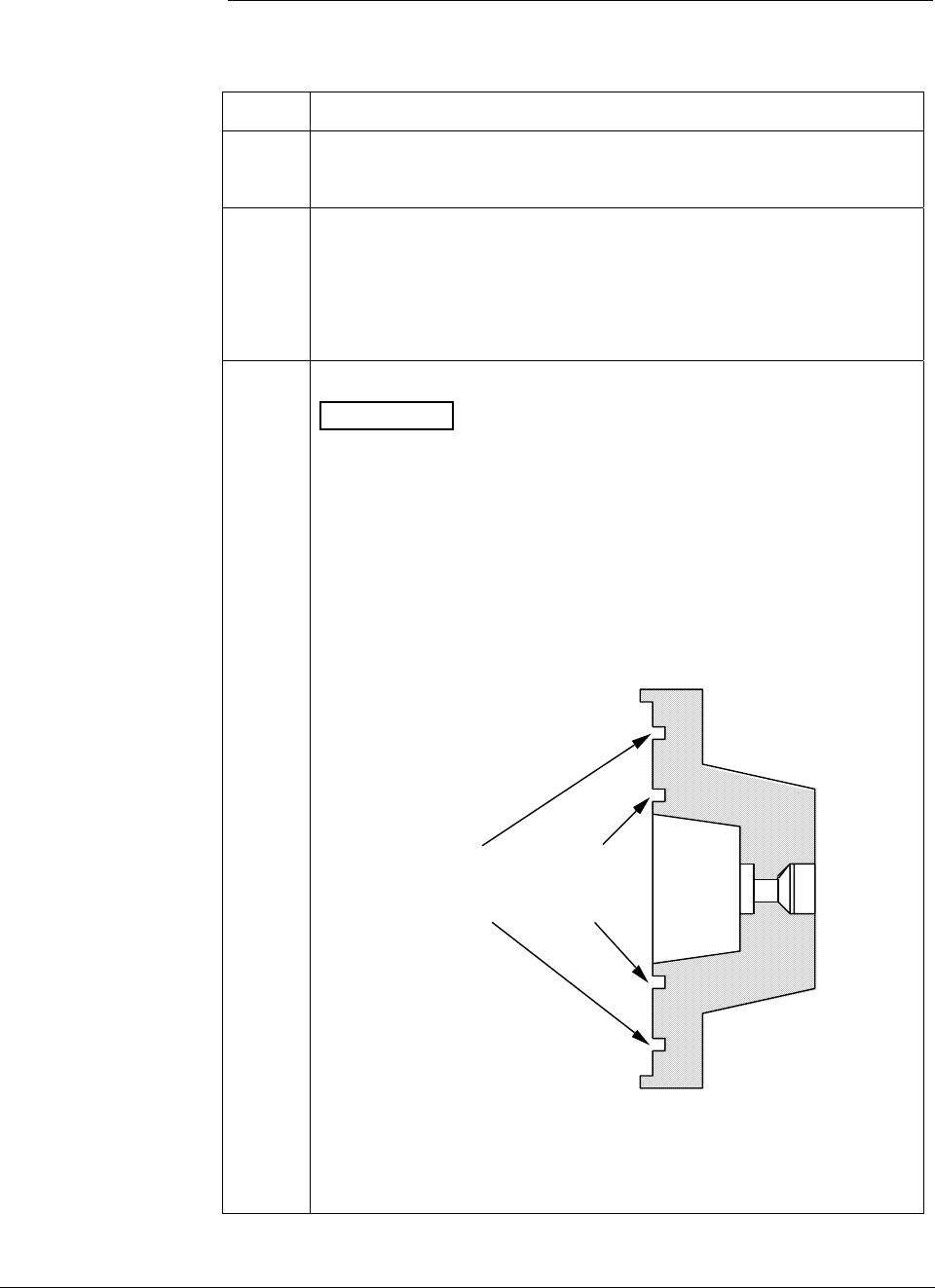

ATTENTION

• We recommend that you install a new O-ring whenever a process

head is removed for cleaning.

• The process head for a GP or an AP transmitter with single-head

design has two O-ring grooves. A large one which is 2 in (50.8

mm) in diameter and a small one which is 1.3 in (33 mm) in

diameter as shown in the following illustration. On high-pressure,

model STG180, GP transmitters, be sure to use a small O-ring in

the smaller/inner groove. On other models of GP and AP

transmitters, use a large O-ring in the larger/outer groove.

Never

use both O-rings together.

Larger O-ring

groove for

lower pressure

applications

Smaller O-ring

groove for

high pressure

applications

22518

GP/AP Process Head

• For process heads of a GP or AP transmitter with dual-head

design, see detail illustration for differential pressure transmitters

in Step 2.

Continued on next page