242 ST 3000 Release 300 and SFC Model STS103 User’s Manual 6/08

B.1 Possible Solutions/Methods, Continued

Mechanical

(diaphragm) seals,

continued

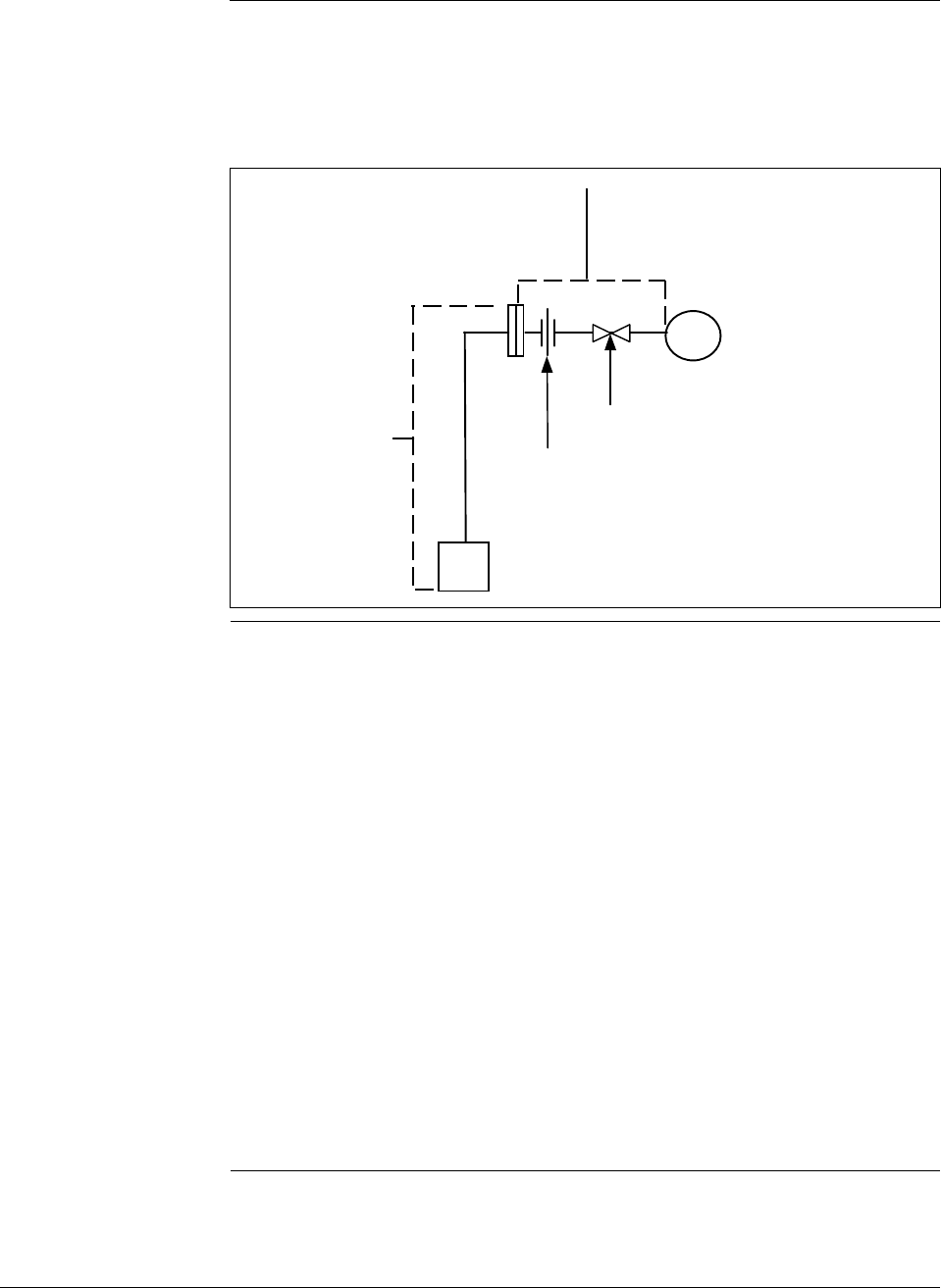

Figure B-5 Piping Installation for Process Pressure Transmitter with

Metal Diaphragm Seal.

Process pressure

transmitter with

metal diaphragm

seal

Pipe union or

coupling

Shut-off valve

Impulse piping, shut-off valve, and

diaphragm seal distance must be as

short as possible and insulated along

with the process pipe or vessel

Electric heating

Most transmitters will withstand higher temperatures at their process

interfaces (bodies) than at their electronics. Normally, it is impractical to

heat transmitter bodies above 225 to 250°F (107 to 121°C) without radiant

and conducted heat exceeding the rating at the electronics (normally

200°F/93°C). Prefabricated insulated enclosures with integral heating

coils and thermostats set at 200°F (93°C) can assure viscosity of fluids

which freeze below 180°F (82°C) while assuring safe transmitter

operation. For water or similar lower-temperature mediums, the control

can be set at 50°F (10°C) to save energy and call for heat only when

temperature and wind conditions require.

Systems can be engineered for uncontrolled, continuous electric heating to

prevent water freezing at 0°F (–18°C) and 20 mph wind velocity, while

not exceeding 225°F (107°C) at the transmitter body at 90°F (32°C)

ambient and zero wind velocity. The operating costs in energy for these

systems usually exceed the high initial cost of the thermostat systems.

Never attempt to maintain freeze points above 100°F (38°C) without

thermostat controls since the Btu required to prevent freezing will

normally exceed the body temperature rating under opposite extremes.

Continued on next page