6/08 ST 3000 Release 300 and SFC Model STS103 User’s Manual 239

B.1 Possible Solutions/Methods, Continued

Sealing liquid

method, continued

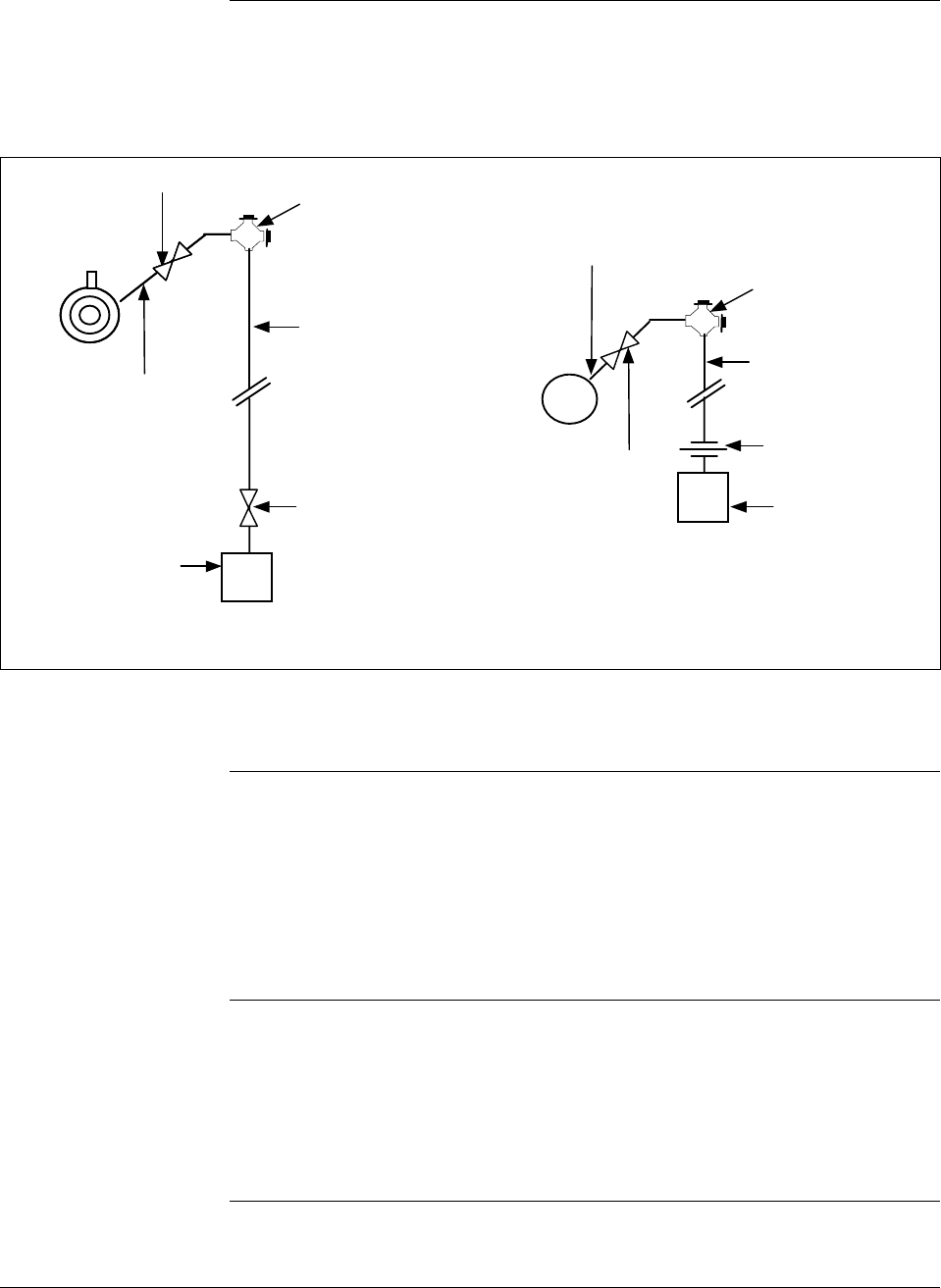

Figure B-2 Piping Installation for Sealing Liquid with Specific Gravity Lighter Than

Process Fluid.

1/2" seamless

pipe nipple 6" long

1/2" shut-off valve (thru

port type desirable)

1/2" seamless pipe

(short as possible to

reduce head effect)

Process pressure

transmitter

1/2" pipe union

or coupling

1/2" pipe cross

with 2 pipe plugs

1/2" shut-off

valve (thru port

type desirable)

1/2" seamless

pipe nipple 6"

long

1/2" pipe cross

with 2 pipe plugs

1/2" 3-valve

manifold,

standard type

Differential

pressure

transmitter

1/2" seamless pipe

(slope at least 1"

per foot downward

Make both HP and LP

connections as shown.

The installation should be checked every 6 to 12 months to verify that the

sealing liquid is at its required specific gravity.

Purging

Purging air or water purges are commonly used to prevent viscous

materials from clogging the impulse lines to pressure, level, or flow

transmitters. The bubbler system, using a constant-air flow regulator, is

particularly common on open tank liquid level applications. No heating of

impulse lines or transmitter is required, but normal precautions are

required to keep water out of the air supply system.

Gas applications

We must not overlook the possibility of condensate freezing in impulse

lines to transmitters measuring gas flow or pressure. Although these

components could be heated similar to water and steam applications, the

simplest and best approach is to install transmitters so that they are self

draining. This means that the impulse lines are connected to the lowest

Continued on next page