244 ST 3000 Release 300 and SFC Model STS103 User’s Manual 6/08

B.1 Possible Solutions/Methods, Continued

Electric heating,

continued

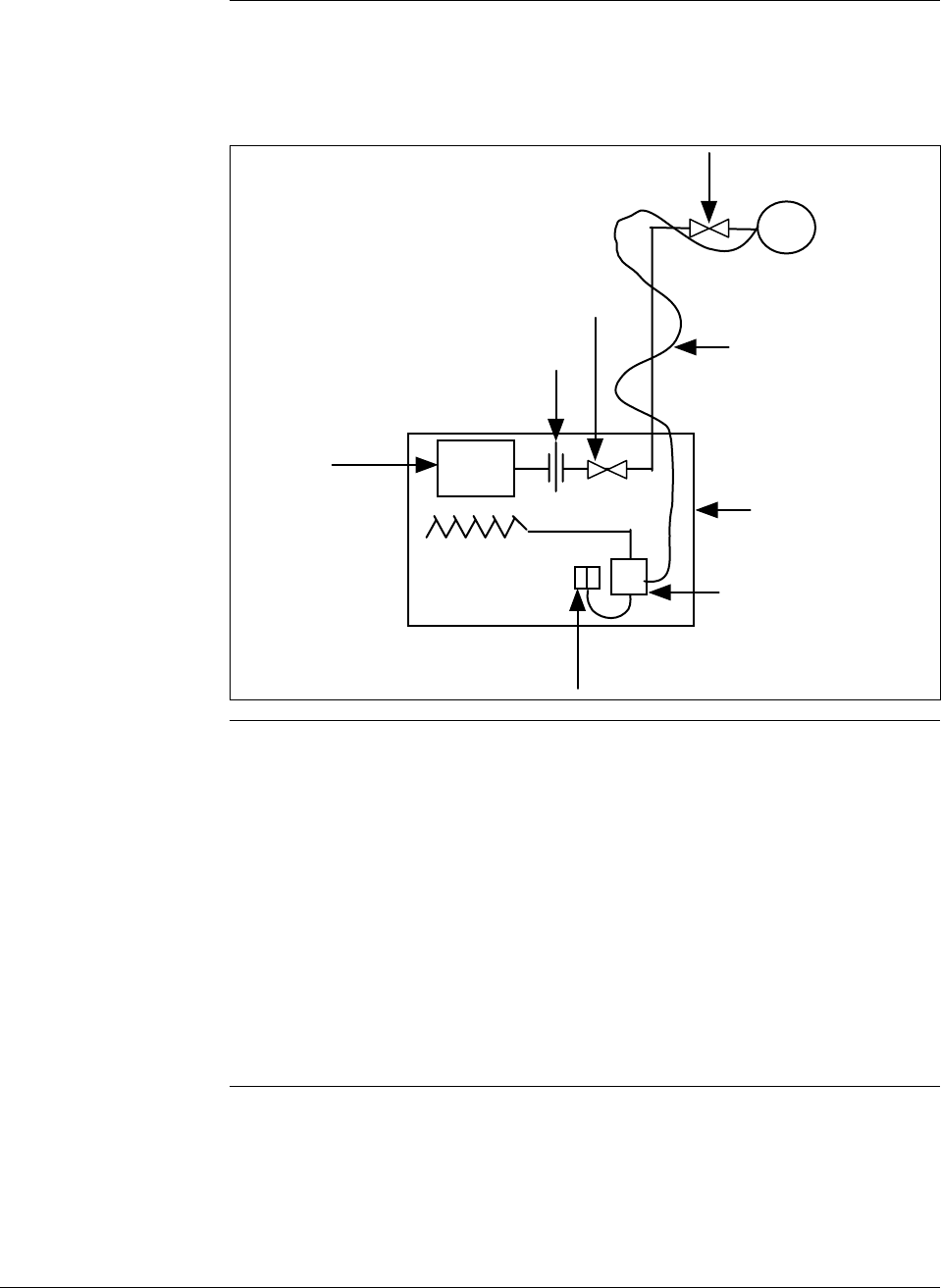

Figure B-7 Piping Installation for Process Pressure Transmitter and

Impulse Piping with Electric Heating Control.

Union or coupling

Process pressure

transmitter

Temperature

controller

(thermostat)

Temperature

sensor

Insulated

enclosure

Shut-off valve

Shut-off valve

Electric heating

cable

Steam heating

Steam heating is perhaps the most common, yet potentially the most

damaging method of protecting transmitters from freeze-ups. Since steam

is generated for use in the overall process operation, it is considered an

available by-product. The most important point to remember when steam

heating transmitter meter bodies is the temperature of the steam that will

be used and its pressure. We recommend that you review the next

paragraph Superheated steam considerations to get a better understanding

of the temperature problem with steam heating. In brief, do not assume

that 30 psig steam is 274°F (134°C) and cannot damage a transmitter rated

for 250°F (121°C). With steam heating, as with electrical, you should use

insulated transmitter body housing, impulse piping and valves.

Continued on next page