238 ST 3000 Release 300 and SFC Model STS103 User’s Manual 6/08

B.1 Possible Solutions/Methods, Continued

Sealing liquid method,

continued

Zerex are solutions of ethylene-glycol with some rust inhibitors and

possibly leak sealants added; they may be used in place of pure ethylene-

glycol.

Another sealing liquid, used in many chemical plants, is dibutylphalate an

oily-type liquid with a specific gravity of 1.045 at 70°F (21°C). It has a

boiling point 645°F (340°C) and does not freeze so it can be used down to

about –20°F (–30°C).

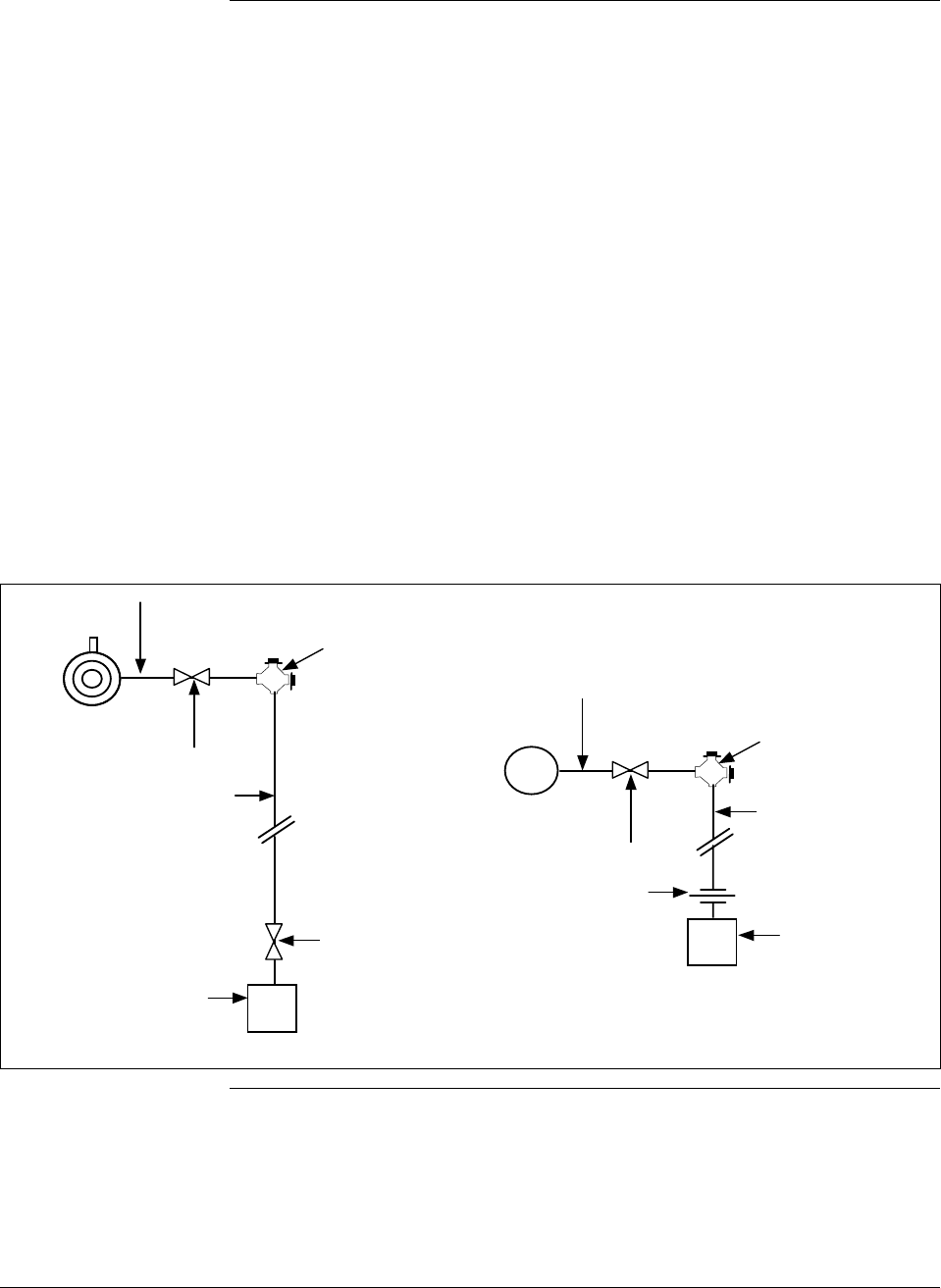

Figures B-1 and B-2 show typical piping installations for this method. The

process fluid must be heated above its freezing point. This is frequently

done by lagging in (insulating) the connecting nipple, shut-off valve and

“T” connector with the process piping. Where the process piping itself

requires heating, a steam or electric trace is run around their components

with consideration given to the boiling point of the sealing liquid.

Figure B-1 Piping Installation for Sealing Liquid With Specific Gravity Heavier Than

Process Fluid.

1/2" seamless pipe nipple 6" long

1/2" shut-off valve (thru

port type desirable)

1/2" pipe cross

with 2 pipe plugs

1/2" seamless pipe

(slope at least 1"

per foot downward

1/2" 3-valve

manifold,

standard type

1/2" seamless pipe

(short as possible to

reduce head effect)

Differential

pressure

transmitter

Process pressure

transmitter

1/2" pipe union

or coupling

1/2" pipe cross

with 2 pipe plugs

1/2" shut-off valve (thru

port type desirable)

1/2" seamless pipe nipple 6" long

Continued on next page