6/08 ST 3000 Release 300 and SFC Model STS103 User’s Manual 137

7.7 Liquid Level Measurement - Pressurized Tank, Continued

Procedure, continued

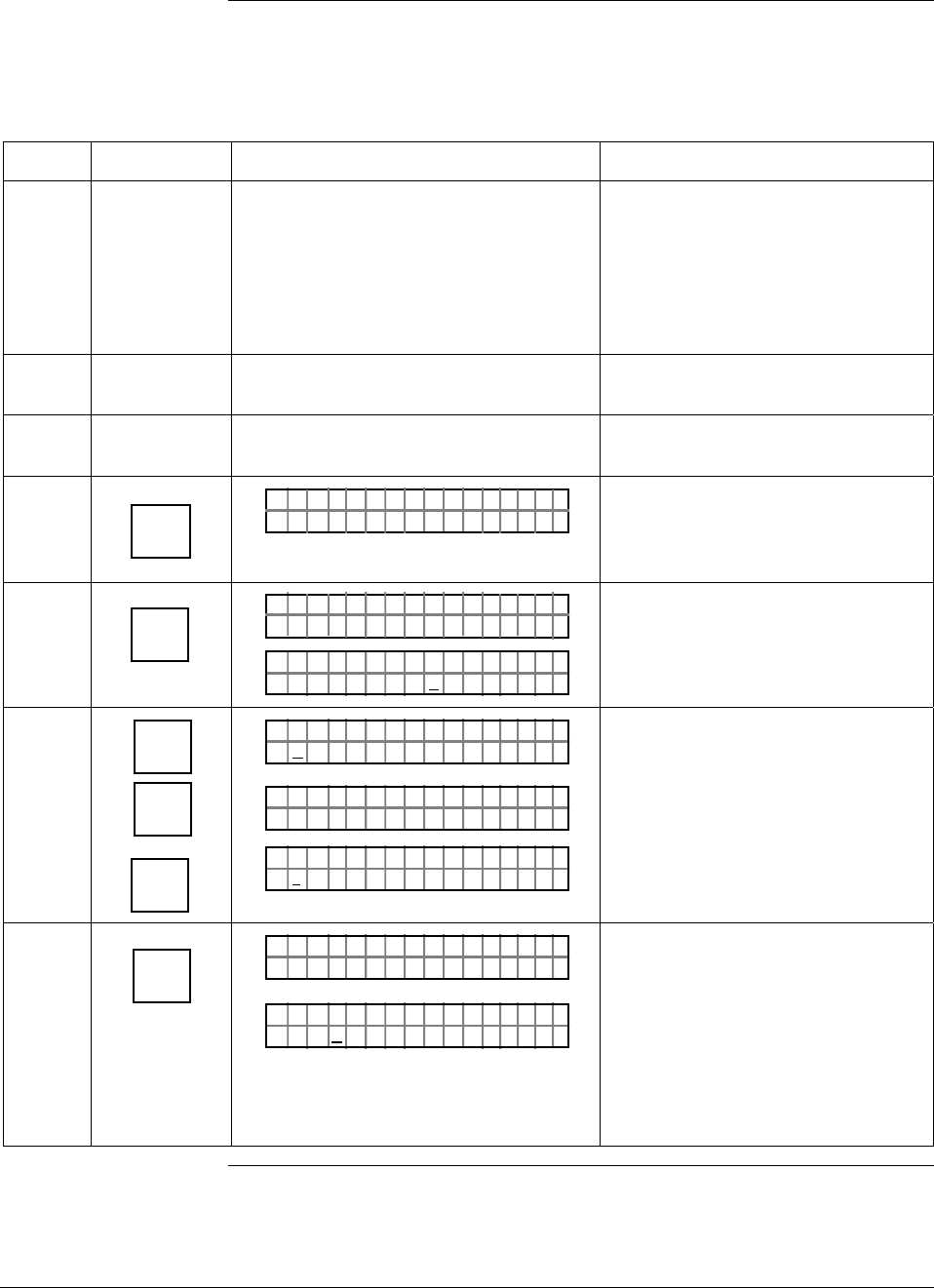

Table 42 Starting Up DP Transmitter for Liquid Level Measurement in Pressurized Tank

Step Press Key Read Display or Action Description

1

Connect SFC across loop wiring and

turn it on. If possible, locate SFC where

you can also view receiver instrument in

loop. If you want to verify transmitter

output, connect a precision milliammeter

or voltmeter in loop to compare

readings.

See Figure 38 for sample SFC and

meter connections in a typical

analog loop with a differential

pressure type transmitter.

2

Close block-off valves A and B. See Figure 42 for sample piping

arrangement.

3

Open plugs C and D. Allow system to stabilize at head

pressure.

4

DE READ

A

ID

TA ON.G

?TRIPS SECURED?

Be sure any switches that may trip

alarms or interlocks associated with

analog loop are secured or turned

off.

5

NON-VOL

ENTER

(Yes)

TA ON.G

SFC WORKING.. .

LIN AG NO.DP T

P T3Ø11

Confirm that “TRIPS” are secured

and establish communications with

sample transmitter PT 3011

6

E

LRV

0%

SET

G

NON-VOL

ENTER

(Yes)

PTLRV 3Ø111

Ø

. ØØØØ

"

H2O

_

39F

PTLRV

RV

3Ø11

L

1

?SET

PTLRV 3Ø111

1

.Ø5 32

"

H2O

_

39F

Read present LRV setting.

Prompt asks if you want to set LRV

to applied pressure.

LRV is set to applied head pressure

H

1

times density of liquid in

reference leg.

7

INPUT

J

OUT-

PUT

PTOUT 3Ø111P

FC WOSING.RK ..

%.Ø

PTOUT 3Ø111P

ØØØ

Call up output for display.

Read 0% output on display for

corresponding empty tank pressure

plus head pressure H

1

. For analog

transmission, check that

milliammeter reading is 4 mA (0%)

output.

Continued on next page