ST 3000 Release 300 and SFC Model STS103 User’s Manual 6/08

124

7.2 Startup Tasks

About startup

Once you have installed and configured a transmitter, you are ready to

start up the process loop. Startup usually includes

• Applying process pressure to the transmitter,

• Checking zero input, and

• Reading input and output.

You can also run an optional output check to “ring out” an analog loop

prior to startup.

Procedure reference

The actual steps in a startup procedure will vary based on the type of

transmitter and the measurement application. In general, we use the SFC

to check the transmitter’s input and output under static process

conditions, and make adjustments as required before putting the

transmitter into full operation with the running process.

Choose the applicable procedure to reference in this section from Table

37 based on your type of transmitter and the measurement application.

The reference procedure will give you some idea of the typical tasks

associated with starting up a transmitter in a given application.

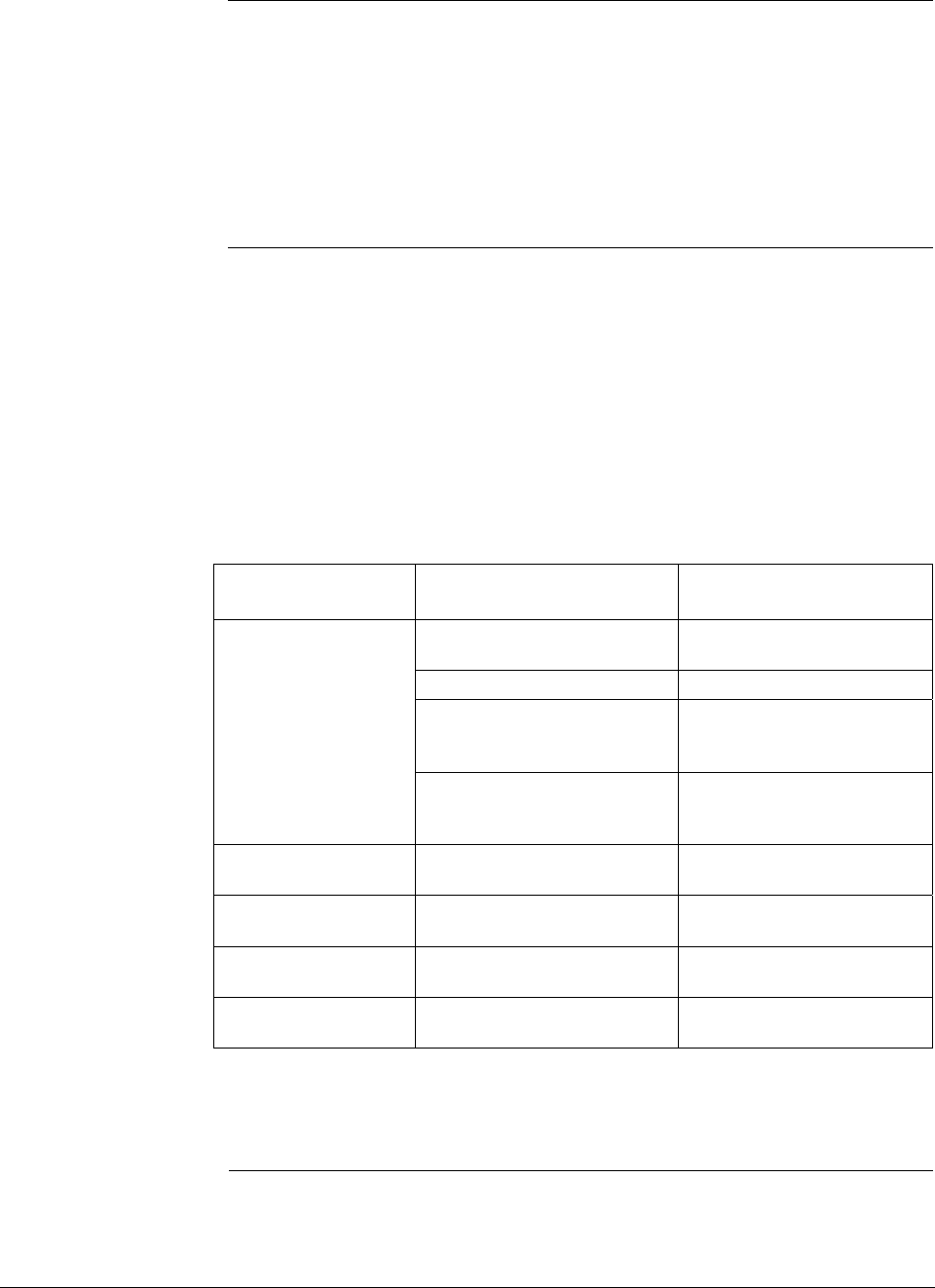

Table 37 Startup Procedure Reference

IF transmitter type

is . . .

AND application is . . . THEN reference

procedure in section . . .

Differential

Pressure (DP)

Flow Measurement 7.4

Pressure Measurement 7.5

Liquid Level Measurement

for Vented Tank with Dry

Reference Leg

*

7.6

Liquid Level Measurement

for Pressurized Tank with

Liquid-Filled Reference Leg

*

7.7

Gauge Pressure

(GP)

Pressure or Liquid Level

Measurement

**

7.8

Flush Mount Pressure or Liquid Level

Measurement

7.9

Absolute Pressure

(AP)

Pressure Measurement** 7.10

DP with Remote

Seals

Liquid Level Measurement 7.11

* These applications also apply for flange-mounted liquid level type transmitters that

are usually mounted directly to a flange at the zero level of the tank.

** These applications also apply for GP and AP type transmitters equipped with remote

seals. However, you can only confirm that input pressure correlates with transmitter

output in processes using remote seal connections.