• For a 9-wire remote installation:

1. Without pinching or stressing the wires, slide the mounting plate into place.

2. Rotate the mounting plate so that the screws are in the locked position.

3. Tighten the screws, torquing to 6 to 8 in-lbs (0.7 to 0.9 N-m).

4. Replace the end-cap.

Important

When reassembling the meter components, be sure to grease all O-rings.

10.29.1 Core processor LED states

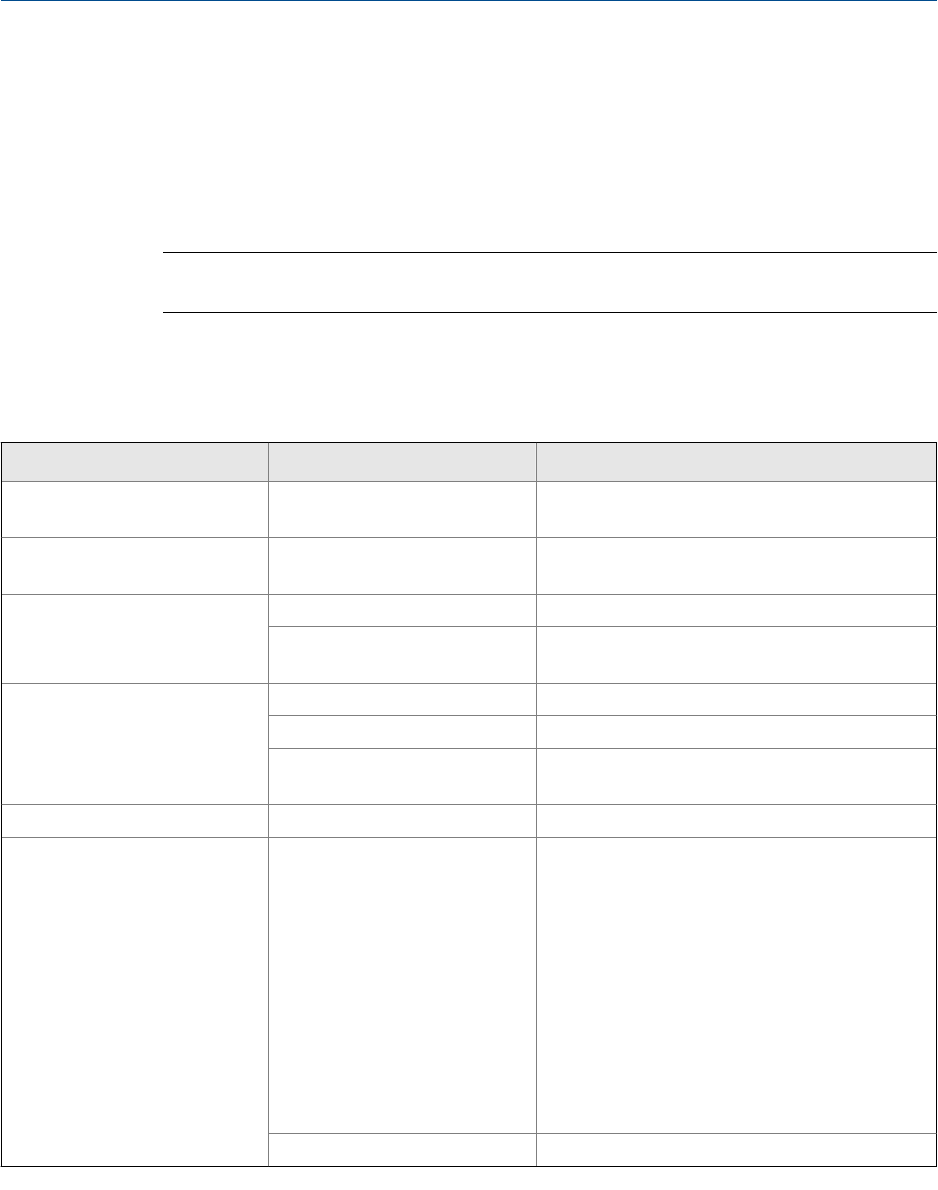

Standard core processor LED statesTable 10-13:

LED state Description Recommended actions

1 flash per second (ON 25%, OFF

75%)

Normal operation No action required.

1 flash per second (ON 75%, OFF

25%)

Slug flow (two-phase flow) See Section 10.25.

Solid ON Zero or calibration in progress No action required.

Core processor receiving be-

tween 11.5 and 5 volts

Check power supply to transmitter.

3 rapid flashes, followed by

pause

Sensor not recognized Check wiring between transmitter and sensor.

Improper configuration Check sensor characterization parameters.

Broken pin between sensor and

core processor

The meter requires factory service.

4 flashes per second Fault condition Check alarm status.

OFF Core processor receiving less

than 5 volts

• Verify power supply wiring to core processor.

• If transmitter status LED is lit, transmitter is re-

ceiving power. Check voltage across terminals

1 (VDC+) and 2 (VDC–) in core processor. If

reading is less than 1 VDC, verify power supply

wiring to core processor. Wires may be switch-

ed.

• If transmitter status LED is not lit, transmitter

is not receiving power. Check power supply. If

power supply is operational, internal transmit-

ter, display, or LED failure is possible – the me-

ter may require factory service.

Core processor internal failure The meter requires factory service.

Troubleshooting

214 Micro Motion

®

Model 1700 Transmitters with Analog Outputs