10.4 Density measurement problems

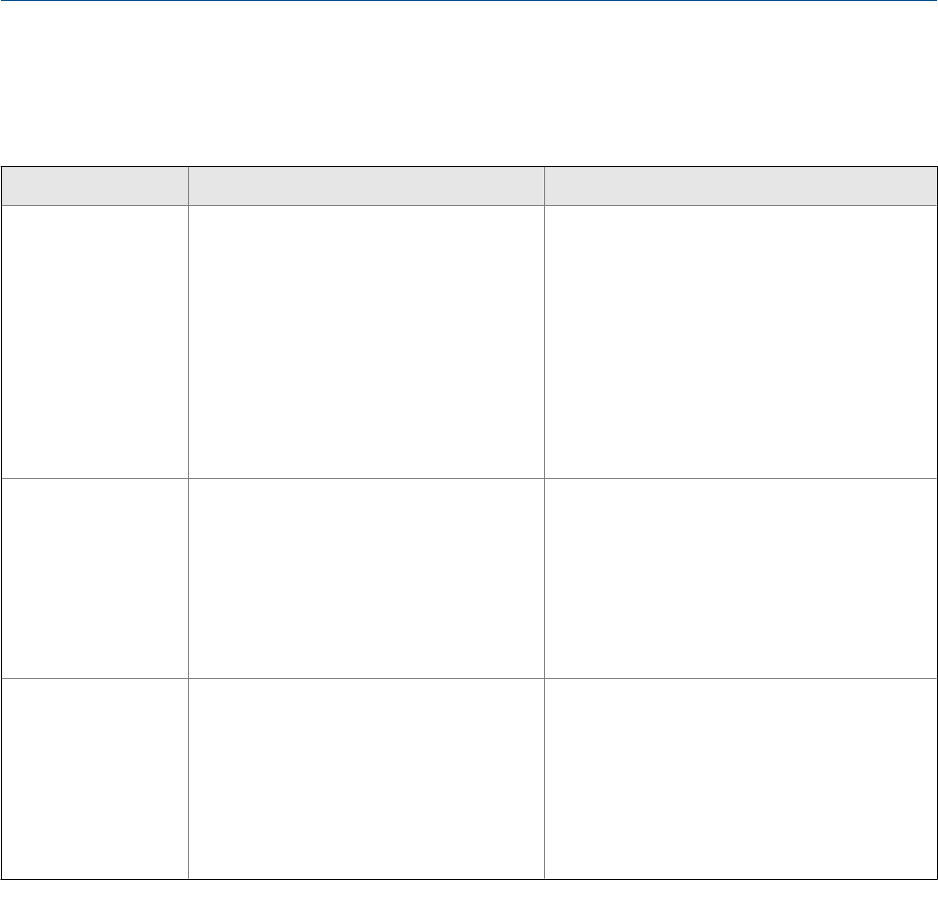

Density measurement problems and recommended actionsTable 10-4:

Problem Possible causes Recommended actions

Inaccurate density

reading

• Problem with process fluid

• Incorrect density calibration factors

• Wiring problem

• Incorrect flowmeter grounding

• Slug flow

• Plugged or coated flow tube

• Incorrect sensor orientation

• RTD failure

• Physical characteristics of sensor have

changed

• Check the wiring between the sensor and

transmitter. See Section 10.10.

• Check grounding. See Section 10.11.

• Check your process conditions against the

values reported by the flowmeter.

• Verify that all of the characterization parame-

ters match the data on the sensor tag.

• Check for slug flow. See Section 10.25.

• If two sensors with similar frequency are too

near each other, separate them.

• Purge the flow tubes.

Unusually high densi-

ty reading

• Plugged or coated flow tube

• Incorrect K2 value

• Incorrect temperature measurement

• RTD problem

• In high frequency meters, this can be an

indication of erosion or corrosion

• In low frequency meters this can indi-

cate tube fouling

• Verify that all of the characterization parame-

ters match the data on the sensor tag.

• Purge the flow tubes.

• Check for coating in the flow tubes.

Unusually low density

reading

• Slug flow

• Incorrect K2 value

• In low frequency meters this can indi-

cate erosion or corrosion

• Check your process conditions against the

values reported by the flowmeter.

• Verify that all of the characterization parame-

ters match the data on the sensor tag.

• Check the wiring between the sensor and

transmitter. See Section 10.10.

• Check for tube erosion, especially if the proc-

ess fluid is abrasive.

Troubleshooting

188 Micro Motion

®

Model 1700 Transmitters with Analog Outputs