Configuration and Use Manual 101

Troubleshooting

Measurement Performance DefaultsTroubleshootingCompensation

11.12 Meter fingerprinting

The meter fingerprinting feature provides snapshots, or “fingerprints,” of twelve process variables, at

four different points of transmitter operation. See Table 11-6.

For all process variables except Mech Zero, the instantaneous value, 5-minute running average,

5-minute running standard deviation, recorded minimum, and recorded maximum are recorded. For

Mech Zero, only the 5-minute running average and 5-minute running standard deviation are recorded.

To use the meter fingerprinting feature:

1. From the

ProLink menu, select Finger Print.

2. Use the

Type pulldown list to specify the point in time for which you want to view data.

3. Use the

Units pulldown list to specify SI or English units.

The display is updated continuously.

Note: Due to the continuous updating, the meter fingerprinting feature can have a negative effect on

other sensor-transmitter communications. Do not open the meter fingerprinting window unless you

plan to use it, and be sure to close it when you no longer need it.

11.13 Troubleshooting filling problems

If the fill cannot be started:

• Check the status LED on the transmitter.

- If it is solid red, the transmitter is in a fault condition and a fill cannot be started. Correct

the fault condition and retry. The cleaning function may be useful.

- If it is solid yellow, the transmitter is in a low-severity fault condition, such as slug flow, or

the fill flow source, target, or discrete outputs are not correctly configured.

Note: A fill can be started under some low-severity fault conditions.

If the system is in slug flow, try using the cleaning function, or pulsing fluid through the

sensor by turning the discrete outputs ON and OFF (if the valves are controlled by discrete

outputs). The Test Discrete Output function can be used for this.

• Ensure that the fill is correctly and completely configured:

- A flow source must be specified.

- A non-zero positive value must be specified for the fill target.

- All outputs required for valve control must be configured.

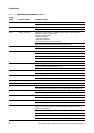

Table 11-6 Meter fingerprinting data

Fingerprint time Description Process variables recorded

Current Present-time values • Mass flow rate

• Volume flow rate

• Density

• Temperature

• Case temperature

•Live zero

• Tube frequency

• Drive gain

• Left pickoff

• Right pickoff

• Board temperature

• Input voltage

Factory Values at time transmitter left factory

Installation Values at time of first sensor zero

Last zero Values at time of most recent sensor zero