98 Micro Motion

®

Model 1500 Transmitters with the Filling and Dosing Application

Troubleshooting

11.11 Checking process variables

Micro Motion suggests that you make a record of the process variables listed below, under normal

operating conditions. This will help you recognize when the process variables are unusually high or

low. The meter fingerprinting feature can also provide useful data (see Section 11.12).

• Flow rate

• Density

•Temperature

• Tube frequency

• Pickoff voltage

•Drive gain

For troubleshooting, check the process variables under both normal flow and tubes-full no-flow

conditions. Except for flow rate, you should see little or no change between flow and no-flow

conditions. If you see a significant difference, record the values and contact Micro Motion customer

service for assistance. See Section 1.8.

Unusual values for process variables may indicate a variety of different problems. Table 11-5 lists

several possible problems and remedies.

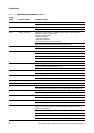

Table 11-5 Process variables problems and possible remedies

Symptom Cause Possible remedy

Steady non-zero flow rate under

no-flow conditions

Misaligned piping (especially in new

installations)

Correct the piping.

Open or leaking valve Check or correct the valve mechanism.

Bad sensor zero Rezero the flowmeter. See Section 3.5.

Bad flow calibration factor Verify characterization. See

Section 4.2.