Configuration and Use Manual 95

Troubleshooting

Measurement Performance DefaultsTroubleshootingCompensation

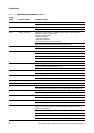

11.10 Status alarms

Status alarm can be viewed with ProLink II. A list of status alarms and possible remedies is provided

in Table 11-4.

Table 11-4 Status alarms and remedies

Alarm

code ProLink II label Possible remedy

A001 CP EEPROM Failure Cycle power to the flowmeter.

The flowmeter might need service. Contact Micro Motion. See Section 1.8.

A002 CP RAM Failure Cycle power to the flowmeter.

The flowmeter might need service. Contact Micro Motion. See Section 1.8.

A003 Sensor Failure Check the test points. See Section 11.23.

Check the sensor coils. See Section 11.25.

Check wiring to sensor. See Section 11.14.2.

Check for slug flow. See Section 11.17.

Check sensor tubes.

A004 Temp Out of Range Check the test points. See Section 11.23.

Check the sensor RTD reading(s). See Section 11.25.

Check wiring to sensor. See Section 11.14.2.

Verify flowmeter characterization. See Section 4.2.

Verify that process temperature is within range of sensor and transmitter.

Contact Micro Motion. See Section 1.8.

A005 Mass Flow Overrange Check the test points. See Section 11.23.

Check the sensor coils. See Section 11.25.

Verify process.

Make sure that the appropriate measurement unit is configured. See

Section 11.19.

Verify 4 mA and 20 mA values. See Section 11.20.

Verify calibration factors in transmitter configuration. See Section 4.2.

Re-zero the transmitter.

A006 Characterize Meter Check the characterization. Specifically, verify the FCF and K1 values. See

Section 4.2.

If the problem persists, contact Micro Motion. See Section 1.8.

A008 Density Out of Range Check the test points. See Section 11.23.

Check the sensor coils. See Section 11.25.

Verify process. Check for air in the flow tubes, tubes not filled, foreign material

in tubes, or coating in tubes.

Verify calibration factors in transmitter configuration. See Section 4.2.

Perform density calibration. See Section 10.5.

A009 Xmtr Initializing Allow the flowmeter to warm up. The error should disappear once the flowmeter

is ready for normal operation.

If alarm does not clear, make sure that the sensor is completely full or

completely empty. Verify sensor configuration and wiring to sensor.

A010 Calibration Failure If alarm appears during a transmitter zero, ensure that there is no flow through

the sensor, then retry.

Cycle power to the flowmeter, then retry.