The flow factor is the percent change in the flow rate per PSI. When entering the

value, reverse the sign.

Example:

If the flow factor is 0.000004 % per PSI, enter −0.000004 % per PSI.

4. Enter Density Factor for your sensor.

The density factor is the change in fluid density, in g/cm

3

/PSI. When entering the

value, reverse the sign.

Example:

If the density factor is 0.000006 g/cm

3

/PSI, enter −0.000006 g/cm3/PSI.

5. Enter Cal Pressure for your sensor.

The calibration pressure is the pressure at which your sensor was calibrated, and

defines the pressure at which there is no pressure effect. If the data is unavailable,

enter 20 PSI.

6. Determine how the transmitter will obtain pressure data, and perform the required

setup.

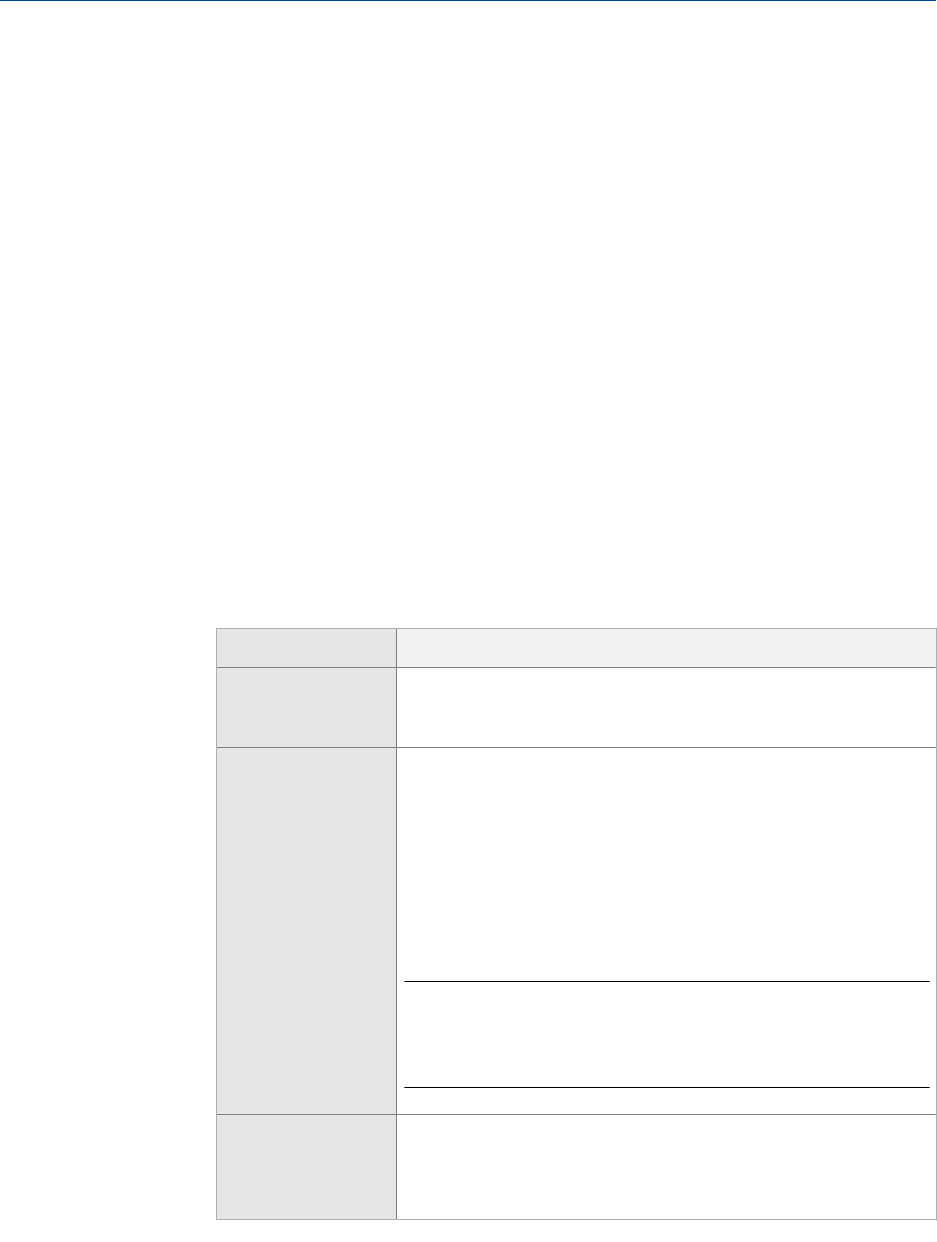

Option

Setup

A user-configured

static pressure val-

ue

a. Set Pressure Units to the desired unit.

b. Set External Pressure to the desired value.

Polling for pres-

sure

(8)

a. Ensure that the primary mA output has been wired to support

HART polling.

b. Choose ProLink > Configuration > Polled Variables.

c. Choose an unused polling slot.

d. Set Polling Control to Poll As Primary or Poll as Secondary, and click

Apply.

e. Set External Tag to the HART tag of the external pressure device.

f. Set Variable Type to Pressure.

Tip

• Poll as Primary: No other HART masters will be on the network.

• Poll as Secondary: Other HART masters will be on the network.

The Field Communicator is not a HART master.

A value written by

digital communica-

tions

a. Set Pressure Units to the desired unit.

b. Perform the necessary host programming and communications

setup to write pressure data to the transmitter at appropriate in-

tervals.

(8) Not available on all transmitters.

Configure process measurement

Configuration and Use Manual 61