10.27.1 Collect pickoff voltage data

ProLink II ProLink > Diagnostic Information

Field Communicator Service Tools > Maintenance > Diagnostic Variables

Overview

Pickoff voltage data can be used to diagnose a variety of process and equipment

conditions. Collect pickoff voltage data from a period of normal operation, and use this

data as a baseline for troubleshooting.

Procedure

1. Navigate to the pickoff voltage data.

2. Observe and record data for both the left pickoff and the right pickoff, over an

appropriate period of time, under a variety of process conditions.

10.28 Check for electrical shorts

Shorts between sensor terminals or between the sensor terminals and the sensor case can

cause the sensor to stop working.

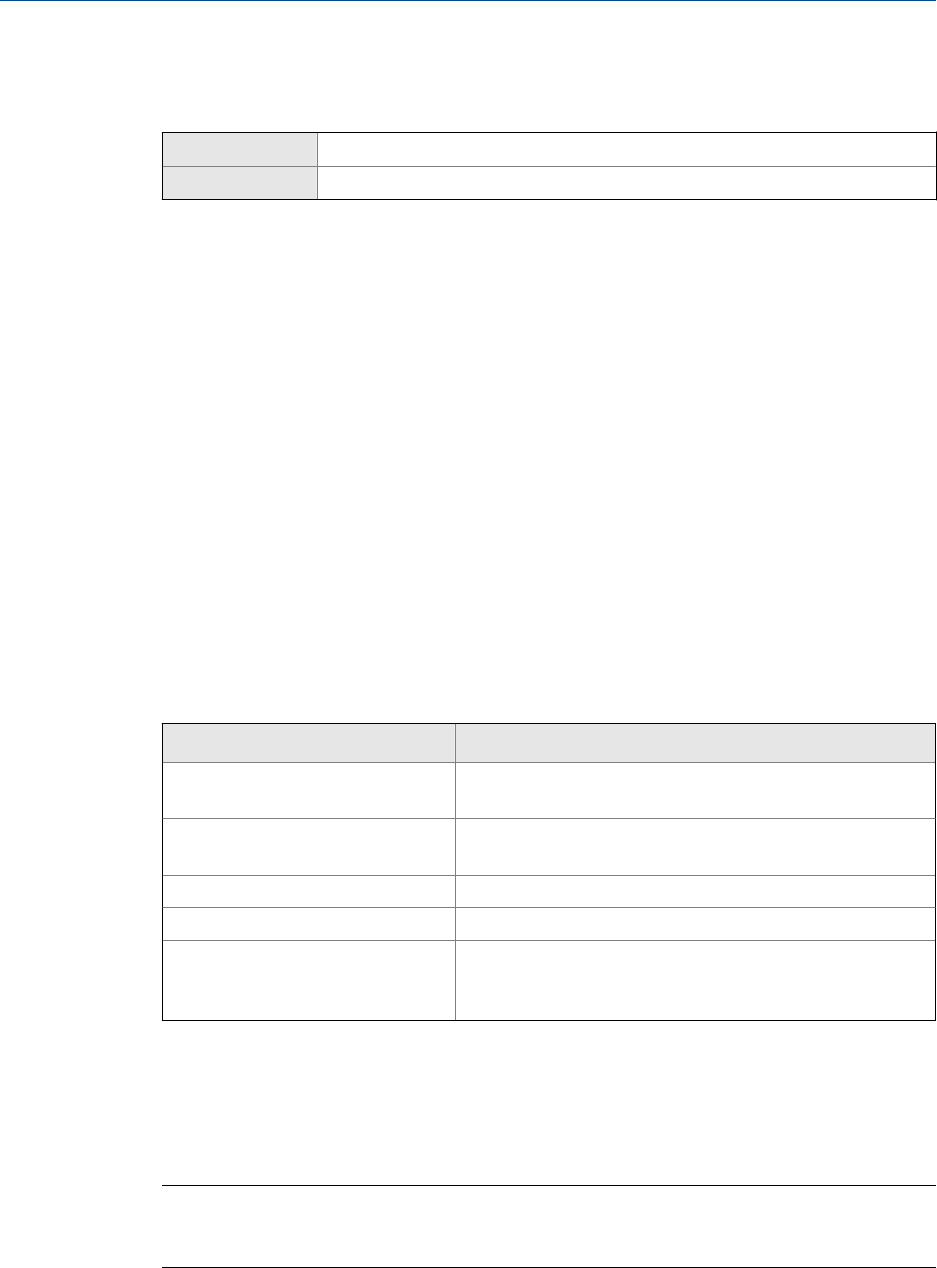

Possible causes and recommended actions for electrical shorts

Table 10-11:

Possible cause Recommended action

Moisture inside the junction box Ensure that the junction box is dry and no corrosion is

present.

Liquid or moisture inside the sensor

case

Contact Micro Motion.

Internally shorted feedthrough Contact Micro Motion.

Faulty cable Replace the cable.

Improper wire termination Verify wire terminations inside sensor junction box. The

Micro Motion document titled 9-Wire Flowmeter Cable Prepa-

ration and Installation Guide may offer some assistance.

10.28.1 Check the sensor coils

Checking the sensor coils can identify electrical shorts.

Restriction

This procedure applies only to 9-wire remote-mount transmitters and remote transmitters with

remote core processors.

Troubleshooting

188 Micro Motion

®

9739 MVD Transmitters