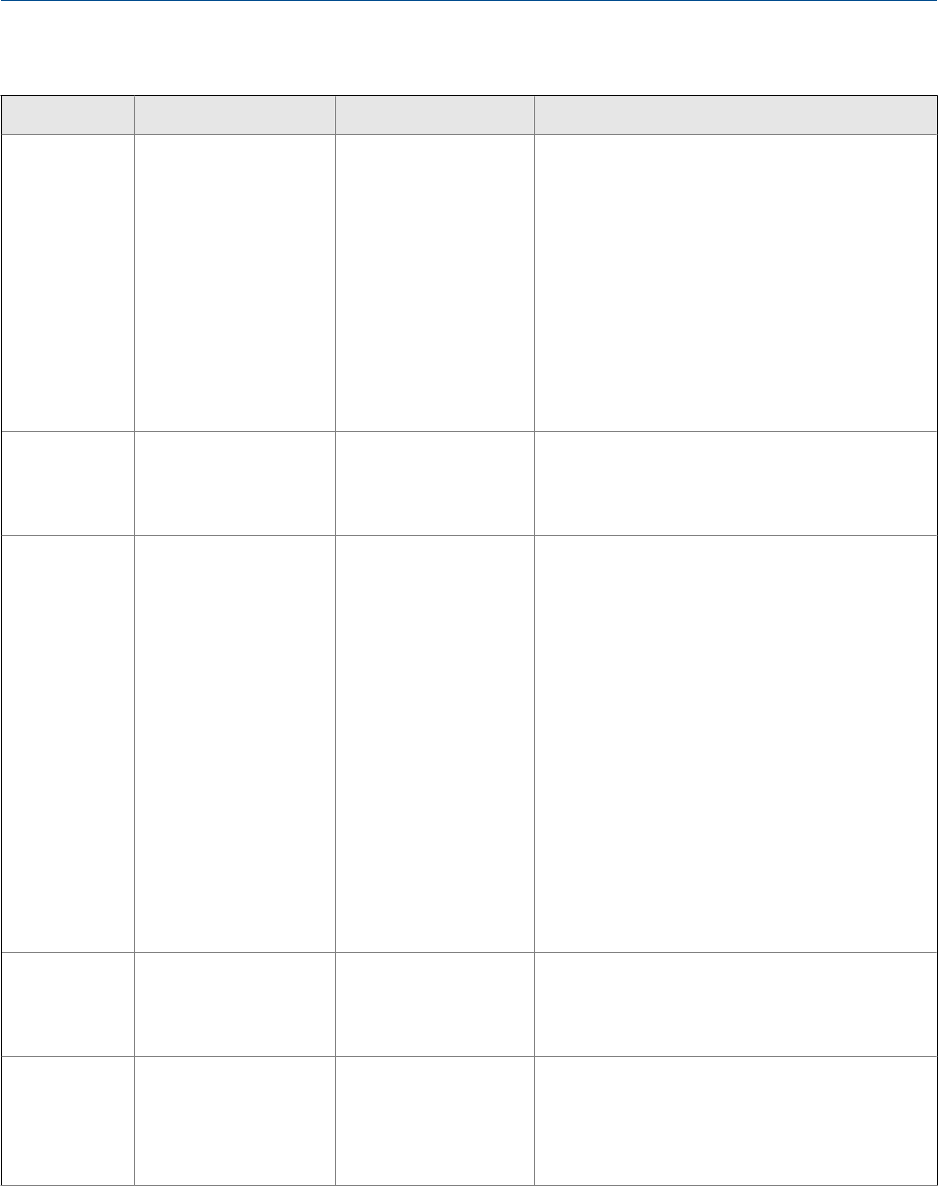

Status alarms and recommended actions (continued)Table 10-2:

Alarm code Description Cause Recommended actions

A005 Mass Flow Rate Over-

range

The measured flow has

exceeded the maxi-

mum flow rate of the

sensor (ΔT greater than

200 µs).

• If other alarms are present, resolve those

alarm conditions first. If the current alarm per-

sists, continue with the recommended ac-

tions.

• Check your process conditions against the val-

ues reported by the flowmeter.

• Check for slug flow. See Section 10.25.

• Check the drive gain and the pickoff voltage.

See Section 10.26 and Section 10.27.

• Check for electrical shorts. See Section 10.28.

• Check the integrity of the sensor tubes.

• Contact Micro Motion.

A006 Characterization Re-

quired

Calibration factors have

not been entered and

the sensor type is incor-

rect.

• Verify that all of the characterization parame-

ters match the data on the sensor tag.

• Contact Micro Motion.

A008 Density Overrange The measured density

has exceeded

10 g/cm

3

.

• If other alarms are present, resolve those

alarm conditions first. If the current alarm per-

sists, continue with the recommended ac-

tions.

• Verify process conditions, checking especially

for air in the flow tubes, tubes not filled, for-

eign material in the tubes, or coating in the

tubes.

• Check for slug flow. See Section 10.25.

• If accompanied by an A003 alarm, check for

electrical shorts. See Section 10.28.

• Verify that all of the characterization parame-

ters match the data on the sensor tag.

• Check the drive gain and the pickoff voltage.

See Section 10.26 and Section 10.27.

• Perform a density calibration.

• Contact Micro Motion.

A009 Transmitter Initializing/

Warming Up

Transmitter is in power-

up mode.

• Allow the meter to warm up.

• Verify that the tubes are full of process fluid.

• Check the wiring between the sensor and

transmitter. See Section 10.10.

A010 Calibration Failure Many possible causes,

such as too much flow

through the sensor dur-

ing a calibration proce-

dure.

• If this alarm appears during zeroing, verify that

there is no flow through the sensor, then retry

the procedure.

• Cycle power to the meter, then retry the pro-

cedure.

Troubleshooting

Configuration and Use Manual 161