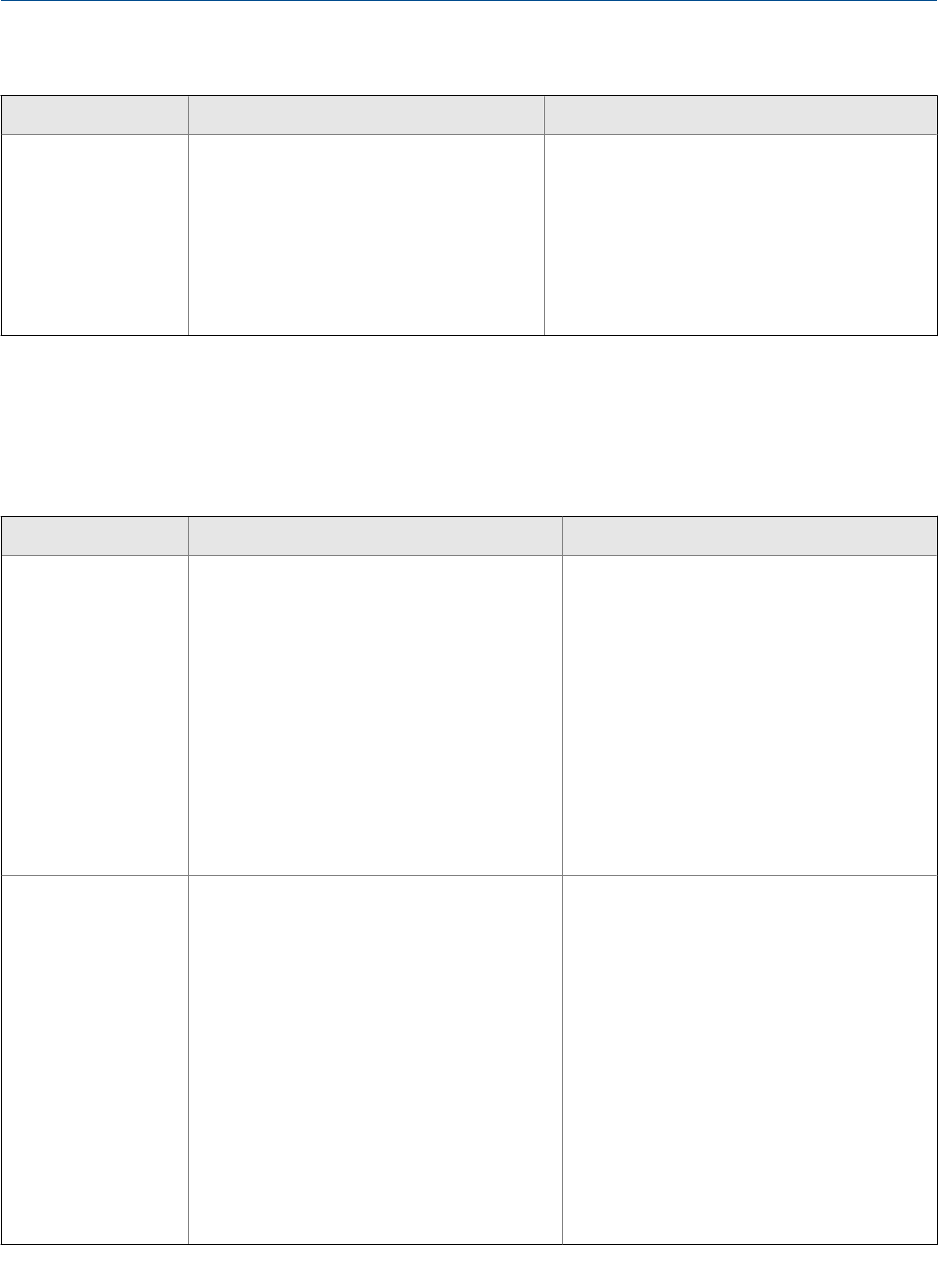

Density measurement problems and recommended actions (continued)Table 10-4:

Problem Possible causes Recommended actions

Unusually low density

reading

• Slug flow

• Incorrect K2 value

• In low frequency meters this can indi-

cate erosion or corrosion

• Check your process conditions against the

values reported by the flowmeter.

• Verify that all of the characterization parame-

ters match the data on the sensor tag.

• Check the wiring between the sensor and

transmitter. See Section 10.10.

• Check for tube erosion, especially if the proc-

ess fluid is abrasive.

10.5 Temperature measurement problems

Temperature measurement problems and recommended actionsTable 10-5:

Problem Possible causes Recommended actions

Temperature reading

significantly different

from process temper-

ature

• RTD failure

• Wiring problem

• Check junction box for moisture or verdi-

gris.

• Perform RTD resistance checks and check

for shorts to case (see Section 10.28.1).

• Confirm the temperature calibration factor

matches the value on the sensor tag.

• Refer to status alarms (especially RTD fail-

ure alarms).

• Disable external temperature compensa-

tion.

• Verify temperature calibration.

• Check the wiring between the sensor and

transmitter. See Section 10.10.

Temperature reading

slightly different from

process temperature

• Sensor temperature not yet equalized

• Sensor leaking heat

• The RTD has a specification of ±1 °C. If the

error is within this range there is no prob-

lem. If the temperature measurement is

outside the specification for the sensor,

contact Micro Motion.

• The temperature of the fluid may be

changing rapidly. Allow sufficient time for

the sensor to equalize with the process flu-

id.

• Insulate the sensor if necessary.

• Perform RTD resistance checks and check

for shorts to case (see Section 10.28.1).

• The RTD may not be making good contact

with the sensor. The sensor may need to

be replaced.

Troubleshooting

Configuration and Use Manual 169