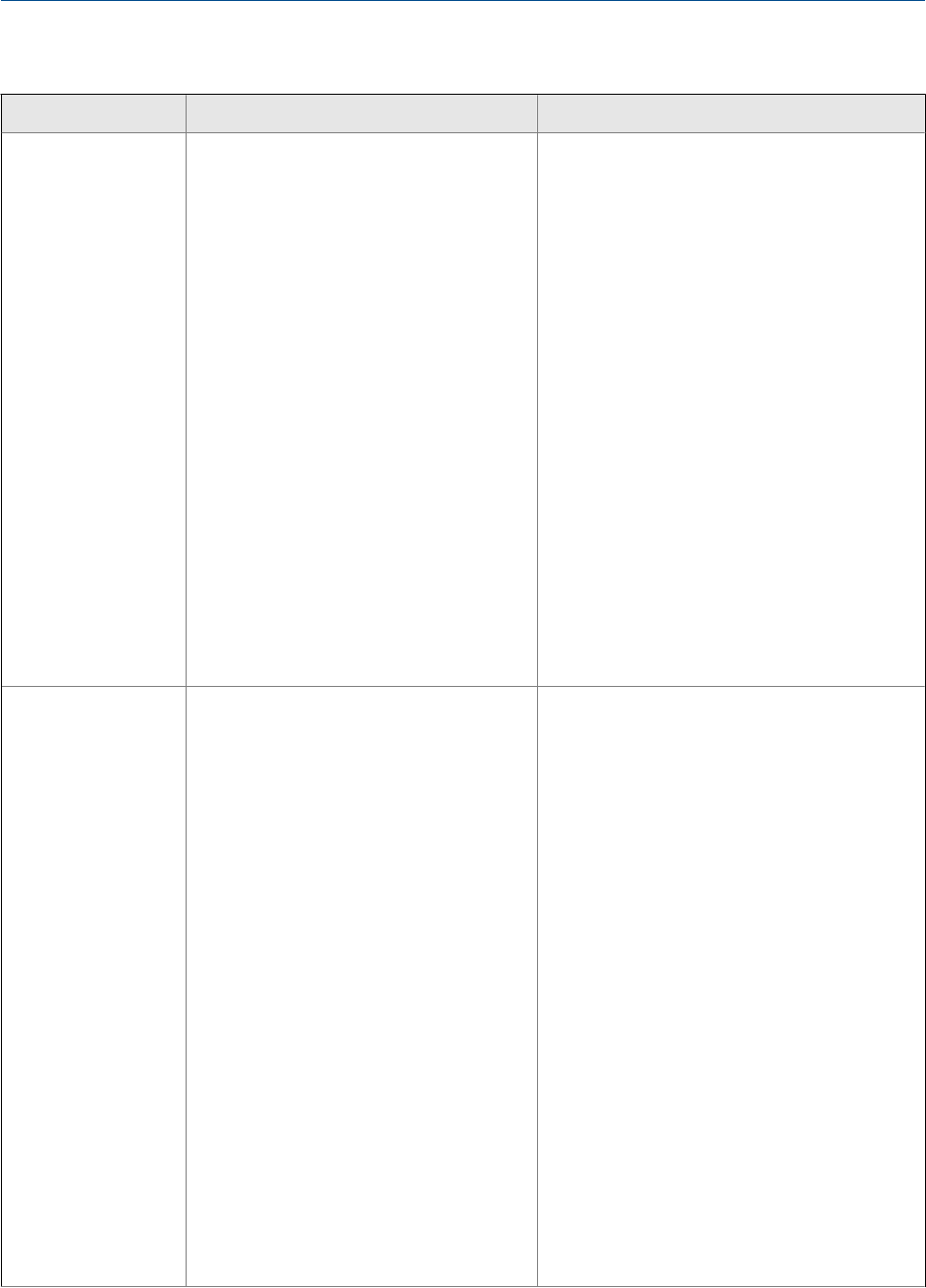

Flow measurement problems and recommended actions (continued)Table 10-3:

Problem Possible causes Recommended actions

Erratic non-zero flow

rate under no-flow

conditions

• Leaking valve or seal

• Slug flow

• Plugged or coated flow tube

• Incorrect sensor orientation

• Wiring problem

• Vibration in pipeline at rate close to sen-

sor tube frequency

• Damping value too low

• Mounting stress on sensor

• Verify that the sensor orientation is appropri-

ate for your application (refer to the sensor

installation manual).

• Check the drive gain and the pickoff voltage.

See Section 10.26 and Section 10.27.

• If the wiring between the sensor and the

transmitter includes a 9-wire segment, verify

that the 9-wire cable shields are correctly

grounded.

• Check the wiring between the sensor and

transmitter. See Section 10.10.

• For sensors with a junction box, check for

moisture in the junction box.

• Purge the flow tubes.

• Check for open or leaking valves or seals.

• Check for sources of vibration.

• Verify damping configuration.

• Verify that the measurement units are con-

figured correctly for your application.

• Check for slug flow. See Section 10.25.

• Check for radio frequency interference. See

Section 10.19.

• Contact Micro Motion.

Erratic non-zero flow

rate when flow is

steady

• Slug flow

• Damping value too low

• Plugged or coated flow tube

• Output wiring problem

• Problem with receiving device

• Wiring problem

• Verify that the sensor orientation is appropri-

ate for your application (refer to the sensor

installation manual).

• Check the drive gain and the pickoff voltage.

See Section 10.26 and Section 10.27.

• If the wiring between the sensor and the

transmitter includes a 9-wire segment, verify

that the 9-wire cable shields are correctly

grounded.

• Check for air entrainment, tube fouling,

flashing, or tube damage.

• Check the wiring between the sensor and

transmitter. See Section 10.10.

• For sensors with a junction box, check for

moisture in the junction box.

• Purge the flow tubes.

• Check for open or leaking valves or seals.

• Check for sources of vibration.

• Verify damping configuration.

• Verify that the measurement units are con-

figured correctly for your application.

• Check for slug flow. See Section 10.25.

• Check for radio frequency interference. See

Section 10.19.

• Contact Micro Motion.

Troubleshooting

Configuration and Use Manual 167