• In general, lower damping values are preferable because there is less chance of data loss, and less

lag time between the actual measurement and the reported value.

• For gas applications, Micro Motion recommends setting Flow Damping to 2.56 or higher.

The value you enter is automatically rounded down to the nearest valid value. Valid

damping values are shown in the following table.

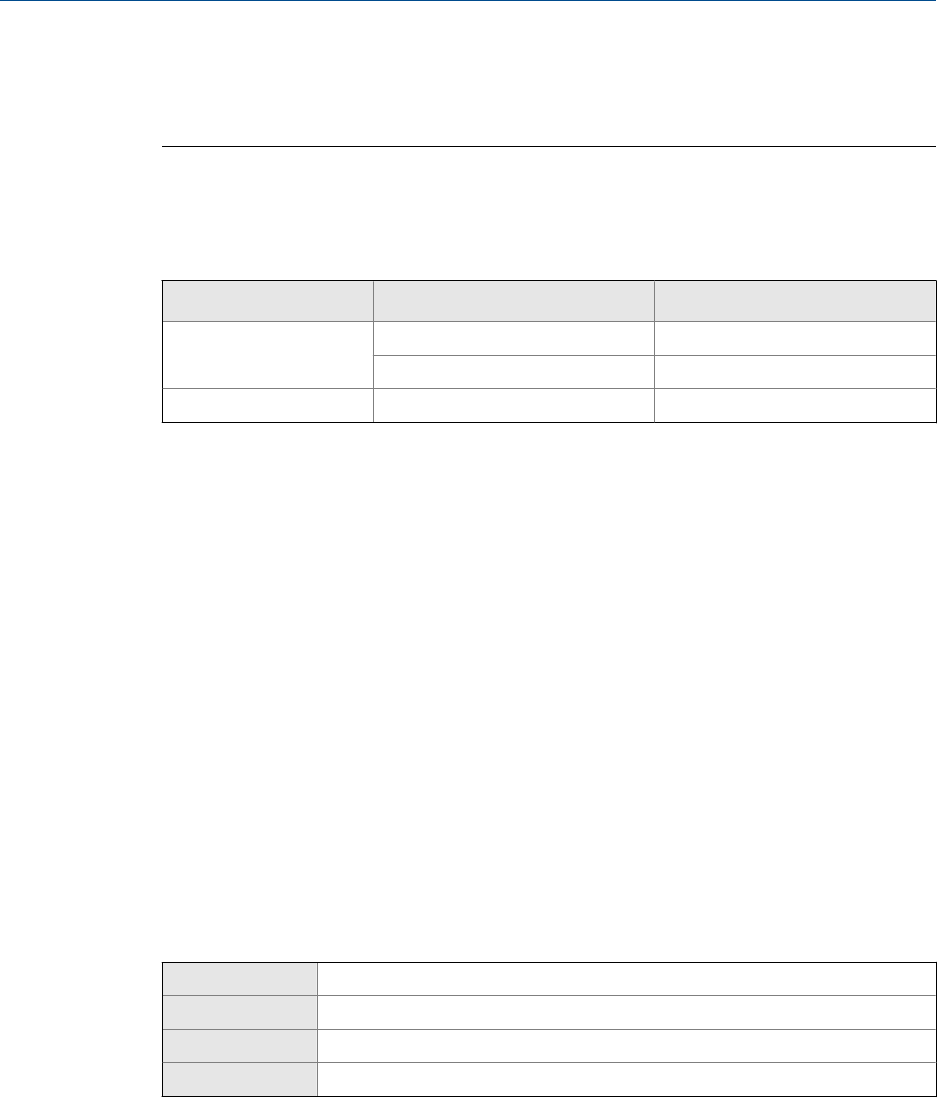

Valid values for Flow DampingTable 4-2:

Core processor type

Update Rate setting

Valid damping values

Standard

Normal

0, 0.2, 0.4, 0.8, ... 51.2

Special

0, 0.04, 0.08, 0.16, ... 10.24

Enhanced Not applicable 0, 0.2, 0.4, 0.8, ... 51.2

Effect of Flow Damping on volume measurement

Flow Damping affects volume measurement for liquid volume data. Flow Damping also affects

volume measurement for gas standard volume data. The transmitter calculates volume

data from the damped mass flow data.

Interaction between Flow Damping and Added Damping

In some circumstances, both Flow Damping and Added Damping are applied to the reported

mass flow value.

Flow Damping controls the rate of change in flow process variables. Added Damping controls

the rate of change reported via the mA output. If mA Output Process Variable is set to Mass

Flow Rate, and both Flow Damping and Added Damping are set to non-zero values, flow

damping is applied first, and the added damping calculation is applied to the result of the

first calculation.

4.1.3 Configure Mass Flow Cutoff

Display

Not available

ProLink II ProLink > Configuration > Flow > Mass Flow Cutoff

ProLink III Device Tools > Configuration > Process Measurement > Flow

Field Communicator Configure > Manual Setup > Measurements > Flow > Mass Flow Cutoff

Overview

Mass Flow Cutoff specifies the lowest mass flow rate that will be reported as measured. All

mass flow rates below this cutoff will be reported as 0.

Configure process measurement

Configuration and Use Manual 27