12.3 Flow measurement problems

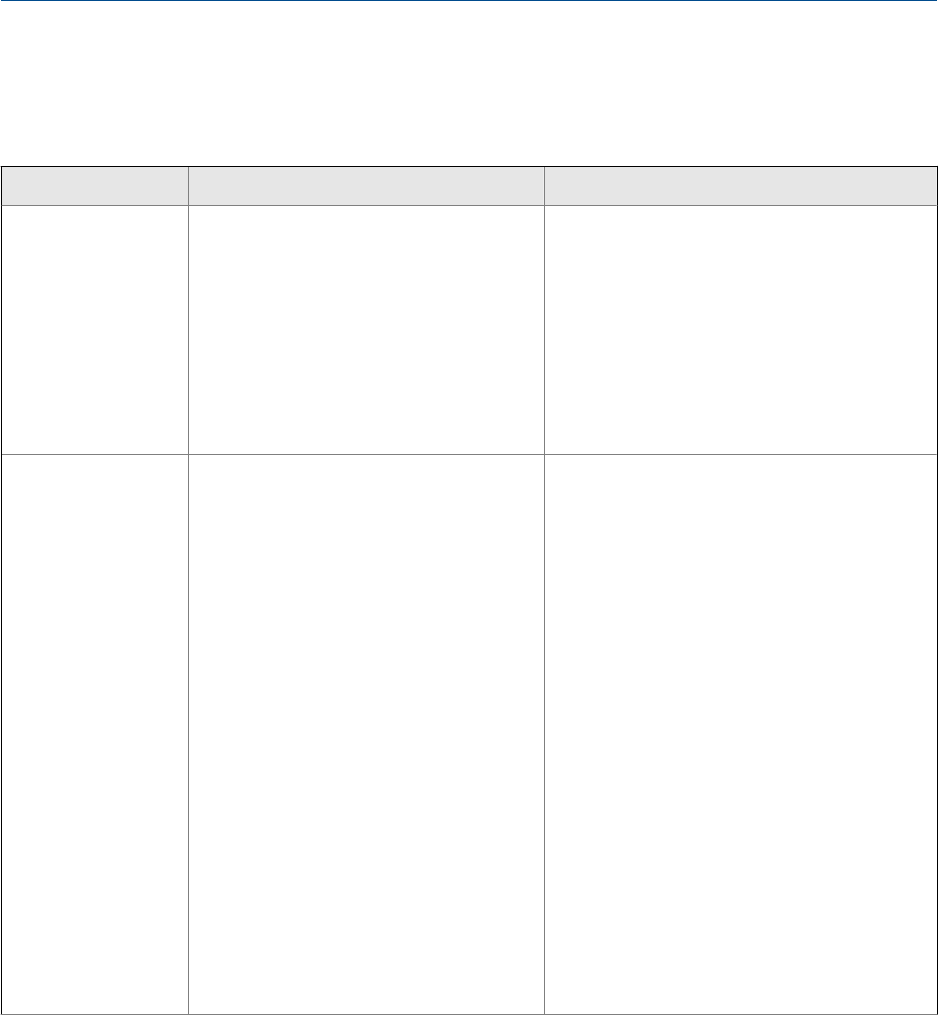

Flow measurement problems and recommended actionsTable 12-3:

Problem Possible causes Recommended actions

Flow indication at no

flow conditions or

zero offset

• Misaligned piping (especially in new in-

stallations)

• Open or leaking valve

• Incorrect sensor zero

• Verify that all of the characterization parame-

ters match the data on the sensor tag.

• If the flow reading is not excessively high, re-

view the live zero. You may need to restore

the factory zero.

• Check for open or leaking valves or seals.

• Check for mounting stress on the sensor

(e.g., sensor being used to support piping,

misaligned piping).

• Contact Micro Motion.

Erratic non-zero flow

rate under no-flow

conditions

• Leaking valve or seal

• Slug flow

• Plugged or coated flow tube

• Incorrect sensor orientation

• Wiring problem

• Vibration in pipeline at rate close to sen-

sor tube frequency

• Damping value too low

• Mounting stress on sensor

• Verify that the sensor orientation is appropri-

ate for your application (refer to the sensor

installation manual).

• Check the drive gain and the pickoff voltage.

See Section 12.26 and Section 12.27.

• If the wiring between the sensor and the

transmitter includes a 9-wire segment, verify

that the 9-wire cable shields are correctly

grounded.

• Check the wiring between the sensor and

transmitter. See Section 12.10.

• For sensors with a junction box, check for

moisture in the junction box.

• Purge the flow tubes.

• Check for open or leaking valves or seals.

• Check for sources of vibration.

• Verify damping configuration.

• Verify that the measurement units are con-

figured correctly for your application.

• Check for slug flow. See Section 12.25.

• Check for radio frequency interference. See

Section 12.13.

• Contact Micro Motion.

Troubleshooting

220 Micro Motion

®

Model 2700 Transmitters with Analog Outputs