12.26 Check the drive gain

Excessive or erratic drive gain may indicate any of a variety of process conditions, sensor

problems, or configuration problems.

To know whether your drive gain is excessive or erratic, you must collect drive gain data

during the problem condition and compare it to drive gain data from a period of normal

operation.

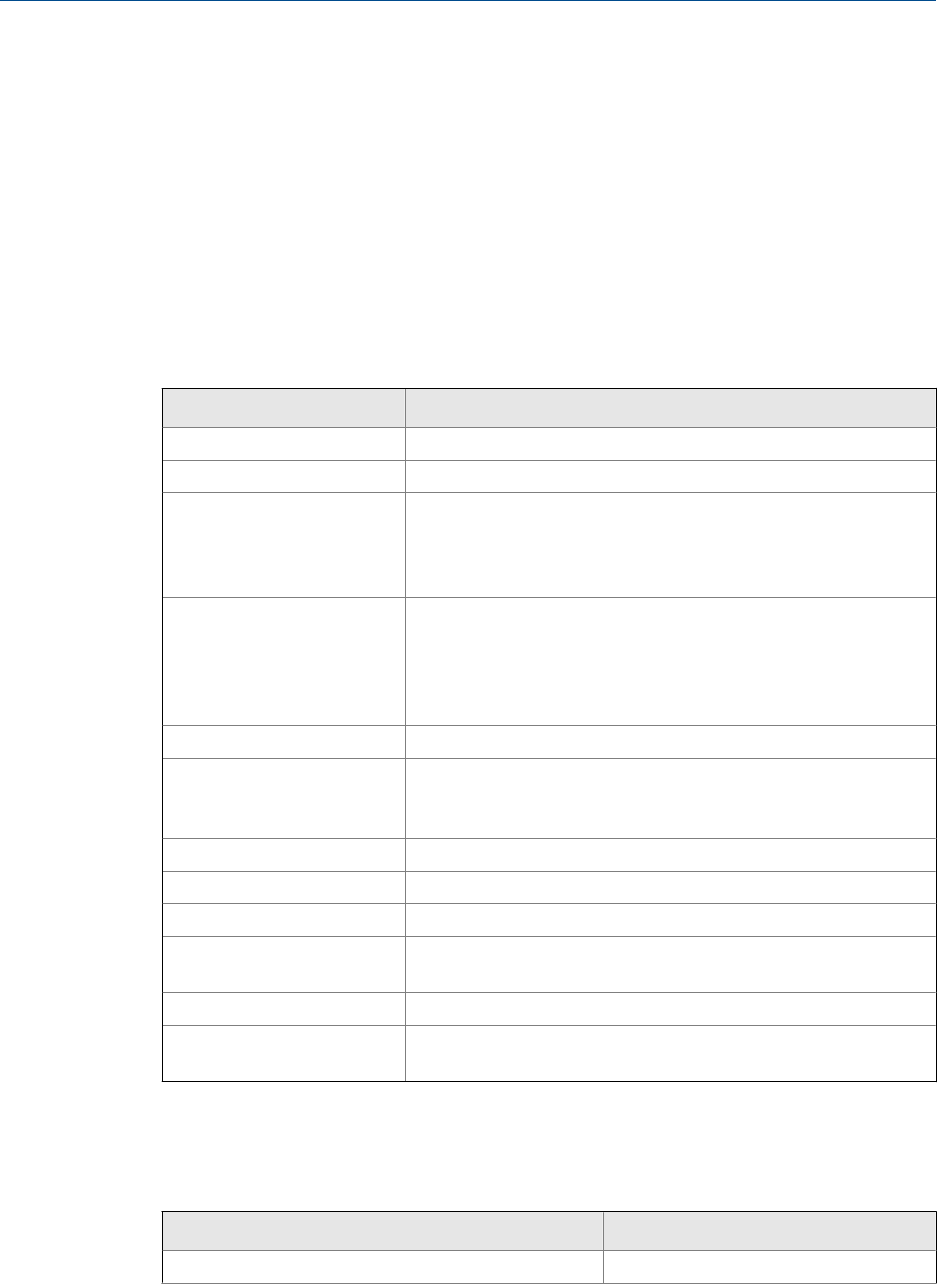

Excessive (saturated) drive gain

Possible causes and recommended actions for excessive (saturated)

drive gain

Table 12-8:

Possible cause Recommended actions

Slug flow Check for slug flow. See Section 12.25.

Partially filled flow tube Correct process conditions so that the flow tubes are full.

Plugged flow tube Check the pickoff voltages (see Section 12.27). If either of them are

close to zero (but neither is zero), plugged tubes may be the source

of your problem. Purge the tubes. In extreme cases, you may need

to replace the sensor.

Cavitation, flashing, or air en-

trainment; settling of two- or

three-phase fluids

• Increase the inlet or back pressure at the sensor.

• If a pump is located upstream from the sensor, increase the dis-

tance between the pump and sensor.

• The sensor may need to be reorientated. Consult the installa-

tion manual for your sensor for recommended orientations.

Drive board or module failure Contact Micro Motion.

Bent flow tube Check the pickoff voltages (see Section 12.27). If either of them are

close to zero (but neither is zero), the flow tubes may be bent. The

sensor will need to be replaced.

Cracked flow tube Replace the sensor.

Sensor imbalance Contact Micro Motion.

Mechanical binding at sensor Ensure sensor is free to vibrate.

Open drive or left pickoff sen-

sor coil

Contact Micro Motion.

Flow rate out of range Ensure that flow rate is within sensor limits.

Incorrect sensor characteriza-

tion

Verify the characterization parameters.

Erratic drive gain

Possible causes and recommended actions for erratic drive gainTable 12-9:

Possible cause Recommended actions

Wrong K1 characterization constant for sensor Verify the K1 characterization parameter.

Troubleshooting

Configuration and Use Manual 239