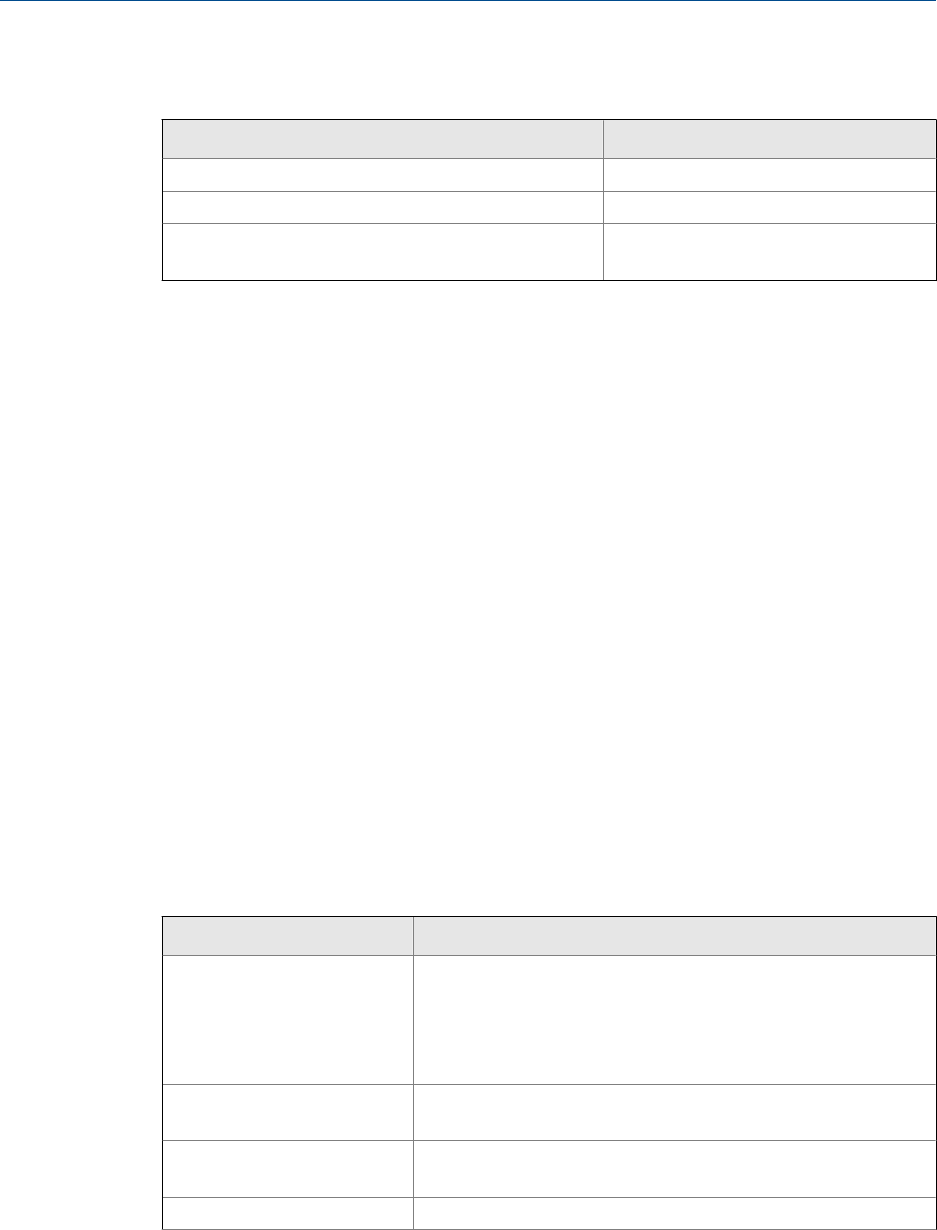

Possible causes and recommended actions for erratic drive gain

(continued)

Table 12-9:

Possible cause Recommended actions

Polarity of pick-off reversed or polarity of drive reversed Contact Micro Motion.

Slug flow Check for slug flow. See Section 12.25.

Foreign material caught in flow tubes • Purge the flow tubes.

• Replace the sensor.

12.26.1 Collect drive gain data

Drive gain data can be used to diagnose a variety of process and equipment conditions.

Collect drive gain data from a period of normal operation, and use this data as a baseline

for troubleshooting.

Procedure

1.

Navigate to the drive gain data.

2. Observe and record drive gain data over an appropriate period of time, under a

variety of process conditions.

12.27 Check the pickoff voltage

If the pickoff voltage readings are unusually low, you may have any of a variety of process

or equipment problems.

To know whether your pickoff voltage is unusually low, you must collect pickoff voltage

data during the problem condition and compare it to pickoff voltage data from a period of

normal operation.

Possible causes and recommended actions for low pickoff voltageTable 12-10:

Possible cause Recommended actions

Air entrainment • Increase the inlet or back pressure at the sensor.

• If a pump is located upstream from the sensor, increase the

distance between the pump and sensor.

• The sensor may need to be reoriented. Consult the installation

manual for your sensor for recommended orientations.

Faulty wiring runs between

the sensor and transmitter

Verify wiring between sensor and transmitter.

Process flow rate beyond the

limits of the sensor

Verify that the process flow rate is not out of range of the sensor.

Slug flow Check for slug flow. See Section 12.25.

Troubleshooting

240 Micro Motion

®

Model 2700 Transmitters with Analog Outputs