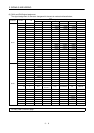

3 - 13

3. SIGNALS AND WIRING

Control

Mode

Signal Symbol

Connec-

tor Pin

No.

Functions/Applications

I/O

Division

PST

Proportion

control

PC CN1B

8

Connect PC-SG to switch the speed amplifier from the

proportional integral type to the proportional type.

If the servo motor at a stop is rotated even one pulse due to any

external factor, it generates torque to compensate for a position

shift. When the servo motor shaft is to be locked mechanically

after positioning completion (stop), switching on the proportion

control signal (PC) upon positioning completion will suppress the

unnecessary torque generated to compensate for a position shift.

When the shaft is to be locked for a long time, switch on the

proportion control signal and torque control signal (TL) at the

same time to make the torque less than the rated by the analog

torque limit.

DI-1

{ ∆

Forced stop EMG CN1B

15

Disconnect EMG-SG to bring the servo motor to a forced stop

state, in which the servo is switched off and the dynamic brake is

operated.

Connect EMG-SG in the forced stop state to reset that state.

DI-1

{{{

Clear CR CN1A

8

Connect CR-SG to clear the position control counter droop pulses

on the leading edge of the signal. The pulse width should be 10ms

or more.

When the parameter No. 42 setting is 1, the pulses are

always cleared while CR-SG are connected.

DI-1

{

<Position/speed control change mode>

Used to select the control mode in the position/speed control

change mode.

(Note) LOP Control Mode

0 Position

1 Speed

Note.0: OFF (LOP-SG open)

1: ON (LOP-SG shorted)

<Speed/torque control change mode>

Used to select the control mode in the speed/torque control change

mode.

(Note) LOP Control Mode

0 Speed

1Torque

Note.0: OFF (LOP-SG open)

1: ON (LOP-SG shorted)

<Torque/position control mode>

Used to select the control mode in the torque/position control

change mode.

(Note) LOP Control Mode

0Torque

1 Position

Control change LOP CN1B

7

Note.0: OFF (LOP-SG open)

1: ON (LOP-SG shorted)

DI-1

Refer to

Functions/

Appli-

cations.