11 - 2

11. CHARACTERISTICS

11.2 Dynamic Brake Characteristics

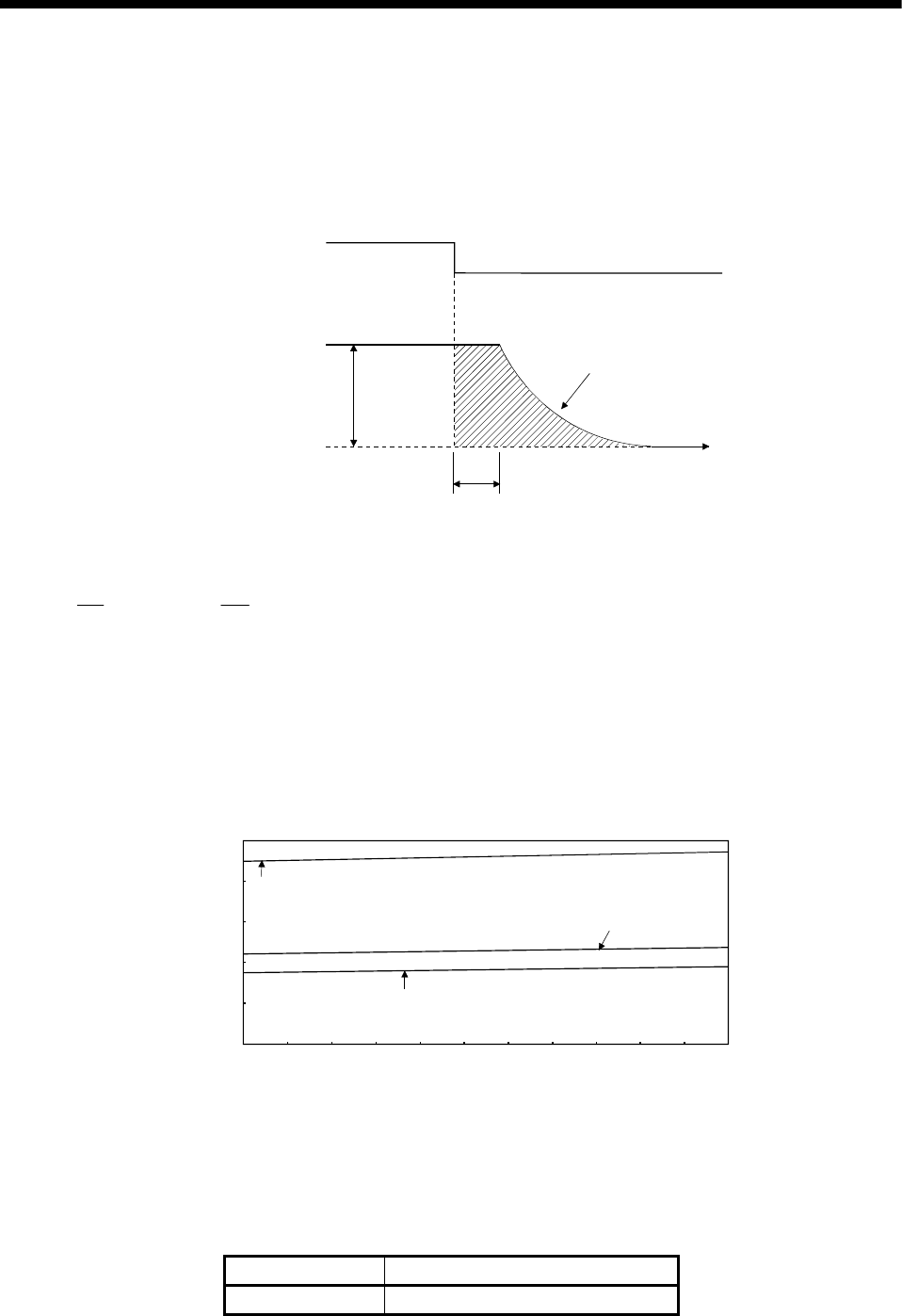

When an alarm, emergency stop or power failure occurs, the dynamic brake is operated to bring the servo

motor to a sudden stop. Fig. 11.2 shows the pattern in which the servo motor comes to a stop when the

dynamic brake is operated. Use Equation 11.1 to calculate an approximate coasting distance to a stop. The

dynamic brake time constant τ varies with the servo motor and machine operation speeds. (Refer to Fig.

11.3.)

V

0

Time constant

τ

Emergency stop (EMG)

OFF

ON

Machine speed

t

e

Time

Fig. 11.2 Dynamic Brake Operation Diagram

Lmax =

60

Vo

x

++

M

L

J

J

1 te (11.1)

L max : Maximum coasting distance [mm][in]

Vo : Machine rapid feedrate [mm/min][in/min]

J

M

: Servo motor inertial moment [kg x cm

2

][oz x in

2

]

J

L

: Load inertia moment converted into equivalent value on servo motor shaft [kg x cm

2

][oz x in

2

]

τ : Brake time constant (Fig. 11.3) [s]

t

e

: Delay time of control section (Fig. 11.2) [s]

(There is internal relay delay time of about 30ms.)

0

0.0005

0.001

0.0015

0.002

0.0025

0 100 400 700 1000 1300 1600

HC-AQ0135

HC-AQ0335

1900

2200

2500 2800

3000

HC-AQ0235

Time constant τ [s]

Speed [r/min]

Fig. 11.3 Dynamic Brake Time Constant

Use the dynamic brake at the load inertia moment indicated in the following table. If the load inertia

moment is higher than this value, the built-in dynamic brake may burn. If there is a possibility that the

load inertia moment may exceed the value, contact Mitsubishi.

Servo Amplifier Load Inertia Moment Ratio [times]

MR-J2-03A5 100