iCOM

Controls Training and Service Manual

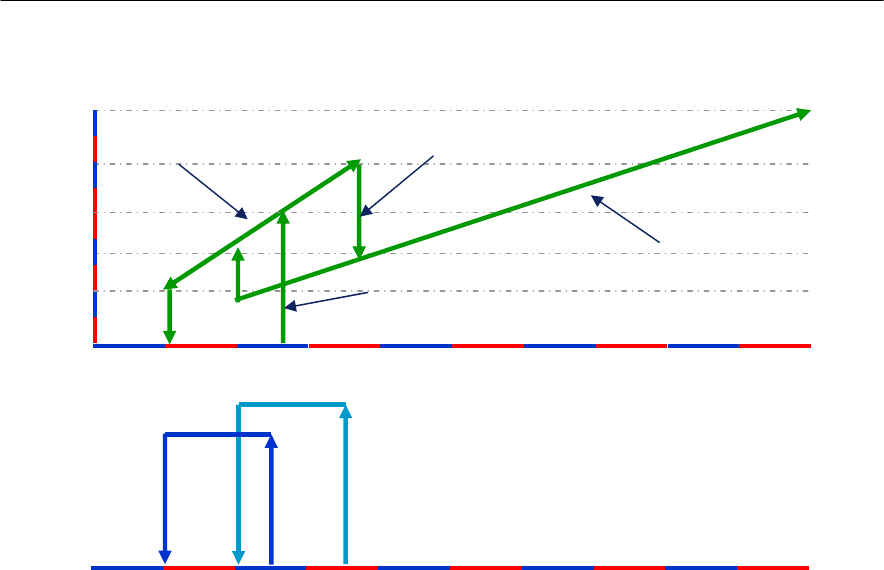

Optional Dual Compressor Digital Scroll Operation

2 compressor operation

C1

C2

Start/ sto

p

PWM

20

35

70

100

35 700%

50

25

On

Of

f

10

20

Of

f

On

p

ressor ONSwitch 1 com

st

Switch 2

n

d

compressor ON

1 com

p

ressor o

p

eration

In the chart above we are defining the Digital Compressor start and stop at the

capacity need and how the compressors load and unload with the PWM from the

controller and the unit setting for temperature control.

Note that the Digital Scroll will run continuously while the head is raised and

lowered as the need for cooling is required from 10% to 100% and vise versa.

Optional Glycool (Econ-O-Cycle) Cooling

When supplied with the Glycool option, the basic unit is supplied with an additional

coil, piping, valve and a Glycol Fluid Sensor (AQ), which is mounted to the unit

supply fluid line and serves as control interface in determining the system

operation. Selection of the glycool or compressorized operation is controlled by

microprocessor using this aquastat to sense the glycol temperature.

The Glycool (Econ-O-Cycle) Cooling program establishes two distinct control

bands for cooling control operation. The first band controls the operation of the

chilled glycol valve and the second controls the operation of the compressors,

either 2-stage or 4-stage.

The microprocessor checks the return air temperature and the entering glycol fluid

temperature to determine a cooling capacity. In order to reduce compressor

cycling and to prevent chilled glycol valve hunting, Glycool (Econ-o-Cycle) cooling

capacity does not become available until the entering chilled glycol fluid

18