iCOM

Controls Training and Service Manual

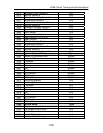

Troubleshooting Checklist

1. Check the obvious before beginning troubleshooting.

A. Be sure that a remote control switch has not been shut off.

B. Be sure that the communication cable is properly connected.

C. Be sure that power is reaching all modules associated with the system.

2. Power down the entire unit during the process of removing or replacing any

component or cable.

A. Serious damage to components may result if this step is not taken.

B. After removal or replacement actions, power may be restored to the unit.

3. Wear a personal ground strap when handling printed circuit boards or

associated connecting cables. Static electricity, besides being annoying, can

damage delicate electronic components.

4. Protect exposed components from accidental contact by personnel or dropped

hardware or tools.

5. When checking voltage, use the correct reference (ground) points. The

chassis is not always the correct ground point, especially within the electronic

housing.

6. Reassemble modules correctly.

A. Observe assembled appearance prior to disassembly.

B. Replace all hardware (especially insulating or nylon hardware) in the same

places and in the same relationship as the original.

7. When advised to check and replace cables, do the following:

A. Inspect for damaged insulation, broken conductors, and/or loose

connectors.

B. Check continuity with an ohm meter (Flex cable while checking.).

C. Make certain that connectors mate firmly with proper receptacles.

8. When changing set points to cause a call for heating or cooling, set the points

at least 10°-15° above (for heating) or below (for cooling) the present room

temperature.

9. Bring the room temperature level to within the working range of the equipment

(35°-90°F) before attempting troubleshooting.

10. Bring the room humidity level to within the working range of the equipment

(35%-65%) before attempting troubleshooting.

146