4.2 Piping ST 3000 Transmitter, Continued

ATTENTION

Care must be taken when installing transmitters on hot processes. The

operating temperature limits for the device (as listed in Table 6) must

not be exceeded. Impulse piping may be used to reduce the temperature

of the process that comes into contact with the transmitter meter body.

As a general rule there is a 56 degree C drop (100 °F) in the temperature

of the process for every foot (305 mm) of ½ inch uninsulated piping.

Process connections

Table 12 describes typical process connections for a given type of

transmitter.

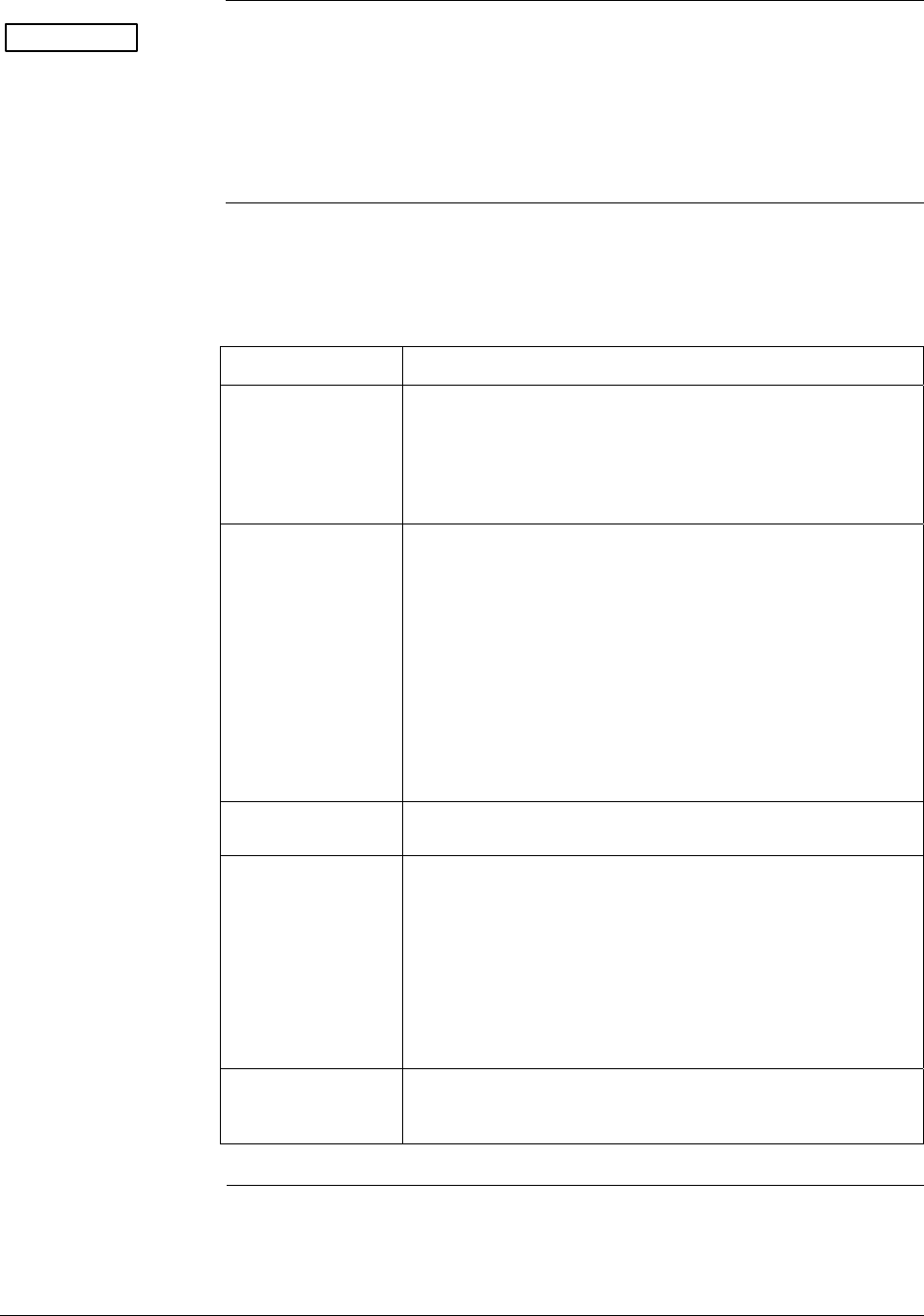

Table 12 Process Connections

Transmitter Type Process Connection

Differential

Pressure

• Process heads with 1/4-inch NPT female connection.

• Flange adapters and manifolds with 1/2-inch female

connection are optional.

• Models with pseudo flange on one side include

2- or 3-inch ANSI class 150 flange.

Gauge Pressure

• Process head with 1/2-inch NPT female connection

(Series 100 transmitters).

• In-line 1/2-inch NPT female connection (STGxxL).

• Process heads with 1/4-inch NPT female connection

(STG9x4).

• Flange adapters and manifolds with 1/2-inch female

connections are optional (STG9x4).

• 2-inch Sanitary Tri-Clamp (STG1xT).

• Flush mount in 1-inch weld sleeve, with O-ring and

locking bolt (STG9xP).

Absolute Pressure

• Process head with 1/2-inch NPT female connection.

(STAx2, x40).

Flange Mounted

Liquid Level

• Small flange 1/2-inch, 1-, 1 ½ - and 2-inch (STFxxT)

• 2, 3- or 4-inch flange with flush or 2-, 4- or 6-inch

extended diaphragm (See Table 13) on high pressure

side.*

• DN 50, 80, or 100 PN 40 flange with flush or 2, 4 or 6

inch extended diaphragm (See Table 13) on High

Pressure Side*.

Remote

Diaphragm Seals

See Model Selection Guide for description of available

Flanged, Threaded, Chemical Tee, Saddle, and Sanitary

process connections.

* Reference side has standard differential pressure process head.

Continued on next page

36 ST 3000 Release 300 Installation Guide 2/05