26

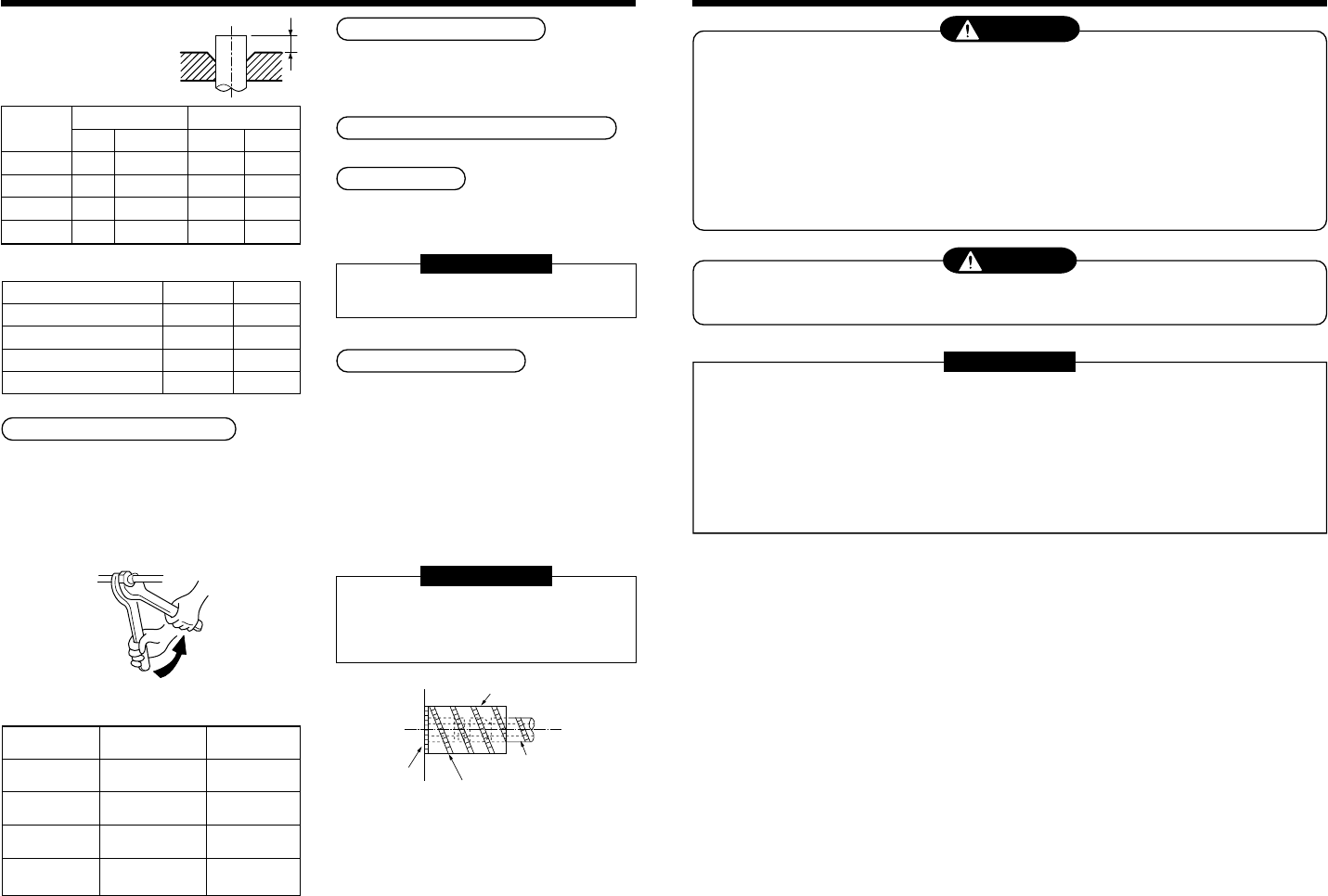

Set notching upward.

Main unit

Pipe side

(Required at the site)

Attached heat insulating pipe

Work using double spanner

• Projection margin in flaring :

B (Unit : mm)

Rigid (Clutch type)

Imperial (Wing nut type)

Connection of refrigerant pipe

Connect all the refrigerant pipes with the flare

connection method

• As the unit is sealed to atmospheric pressure.

It is not abnormal that no “Push....” sound will be

heard upon the removal of the flare nut.

• Ensure use of two spanners for the connecting of the

pipe work to the indoor unit.

• Refer to the following table for tightening torque.

Airtight test/Air purge, etc.

For carrying out airtight test, air purge, gas leak check

and addition of refrigerant refer to the Installation

Manual supplied with the outdoor unit.

Open fully valves of the outdoor unit

Gas leak check

Using a leak detector or soapy water, check for gas

leaks at the connecting pipe work and the caps on the

service valves.

REQUIREMENT

Use a leak detector designed specifically for HFC

refrigerant (R410A, R134a, etc.).

Heat insulating process

Fit heat insulation to the gas and liquid pipes

separately.

During cooling mode, the temperature of the liquid and

the gas pipes are reduced. Therefore ensure sufficient

insulation is fitted to prevent dew condensation.

• On the gas side ensure that the heat insulation used

is heat resistant to a minimum temperature of 120°C

• Using the supplied heat insulation. Insulate the

interconnecting parts of the indoor unit, ensuring that

there is no exposure of any refrigerant pipe work.

As detailed in the illustration below.

REQUIREMENT

Apply the thermal insulation to the pipe connecting

section of the indoor unit securely up to the root

without exposure of the pipe. (The pipe exposed to

the outside causes water leak.)

5

REFRIGERANT PIPING

B

Connecting pipe

outer dia. (mm)

Ø6.4

Ø9.5

Ø12.7

Ø15.9

Tightening torque

(N•m)

14 to 18

(1.4 to 1.8 kgf•m)

33 to 42

(3.3 to 4.2 kgf•m)

50 to 62

(5.0 to 6.2 kgf•m)

68 to 82

(6.8 to 8.2 kgf•m)

Re-tightening

torque (N•m)

18

(1.8 kgf•m)

42

(4.2 kgf•m)

50

(5.0 kgf•m)

68

(6.8 kgf•m)

Outer diam. of

copper pipe

6.4

9.5

12.7

15.9

R410A tool used

R410A R22

0 to 0.5 (Same as left)

0 to 0.5 (Same as left)

0 to 0.5 (Same as left)

0 to 0.5 (Same as left)

Conventional tool used

R410A R22

1.0 to 1.5 0.5 to 1.0

1.0 to 1.5 0.5 to 1.0

1.0 to 1.5 0.5 to 1.0

1.0 to 1.5 0.5 to 1.0

Outer diam. of copper pipe

6.4

9.5

12.7

15.9

R410A R22

1.5 to 2.0 1.0 to 1.5

1.5 to 2.0 1.0 to 1.5

2.0 to 2.5 1.5 to 2.0

2.0 to 2.5 1.5 to 2.0

6

ELECTRIC WORK

WARNING

1. Using the specified wires, ensure the wires are connected and securely fixed so that no

external force can transmit to the connecting part of the terminals.

Poor connection may cause risk of fire, etc.

2. Ensure connection of earth wire. (Grounding work)

Do not connect the earth wire to a gas pipe, mains water pipe, lightning rod, or the earth wire of a telephone.

Incorrect earthing will cause risk of an electric shock.

3. For electrical installation work, strictly follow the Local and national Regulations of each

country and the Installation Manual. A designated power supply must be used.

Capacity shortage of the power supply or incomplete installation may cause an electric shock or a fire.

CAUTION

Ensure an earth leakage breaker is installed.

Failure to install, may result in an electric shock.

REQUIREMENT

• For power supply wiring, strictly conform to the Local authorities in each country.

• For wiring of the power supply of the outdoor units, follow to the outdoor unit Installation Manual.

• Never connect 220–240V control wiring to the terminal blocks (U1, U2, A, B) fault will be. (Caused.)

• Arrange the electrical wiring so that they do not come into contact with high-temperature parts of the pipe

work; this is to prevent the risk of insulation melting and causing a possible accident.

• After connecting wires to the terminal block. Secure wiring with cable clamp.

• Store wiring install control wiring and refrigerant piping within the same line.

• Do not turn on power of the indoor unit until vacuuming of the refrigerant pipe has finished.