OCTOBER 2006 VXA-320 TAPE DRIVE

59

ENVIRONMENTAL SPECIFICATIONS

Air Flow/Cooling Requirements

When mounted in the host enclosure, the tape drive must have adequate air

flow. Ensure that ambient air is allowed to pass through the ventilation holes

shown in Figure 3-1 on page 19. These ventilation holes must not be blocked.

The air flow around the tape drive must be sufficient to prevent tape path

temperatures from exceeding 45 °C (113 °F).

The tape drive is equipped with a temperature sensor. It issues an

overtemperature signal through the LOG SENSE command if the above

temperature is exceeded. You can access temperature data through the LOG

SENSE command. See the VXA-320 (VXA-3) SCSI Reference Manual.

Particulate Contamination Limits

The VXA-320 tape drive is designed to operate in environments that do not

exceed the limits listed in Tabl e 7 -1 7 .

Shock Specifications

The storage and nonoperating shock levels indicate how much shock the tape

drive can withstand when it is not operating. The operating shock levels

indicate how much shock the tape drive can withstand while reading and

writing data. After withstanding this amount of shock, the tape drive operates

normally.

Tab le 7- 18 lists the shock specifications for the tape drive.

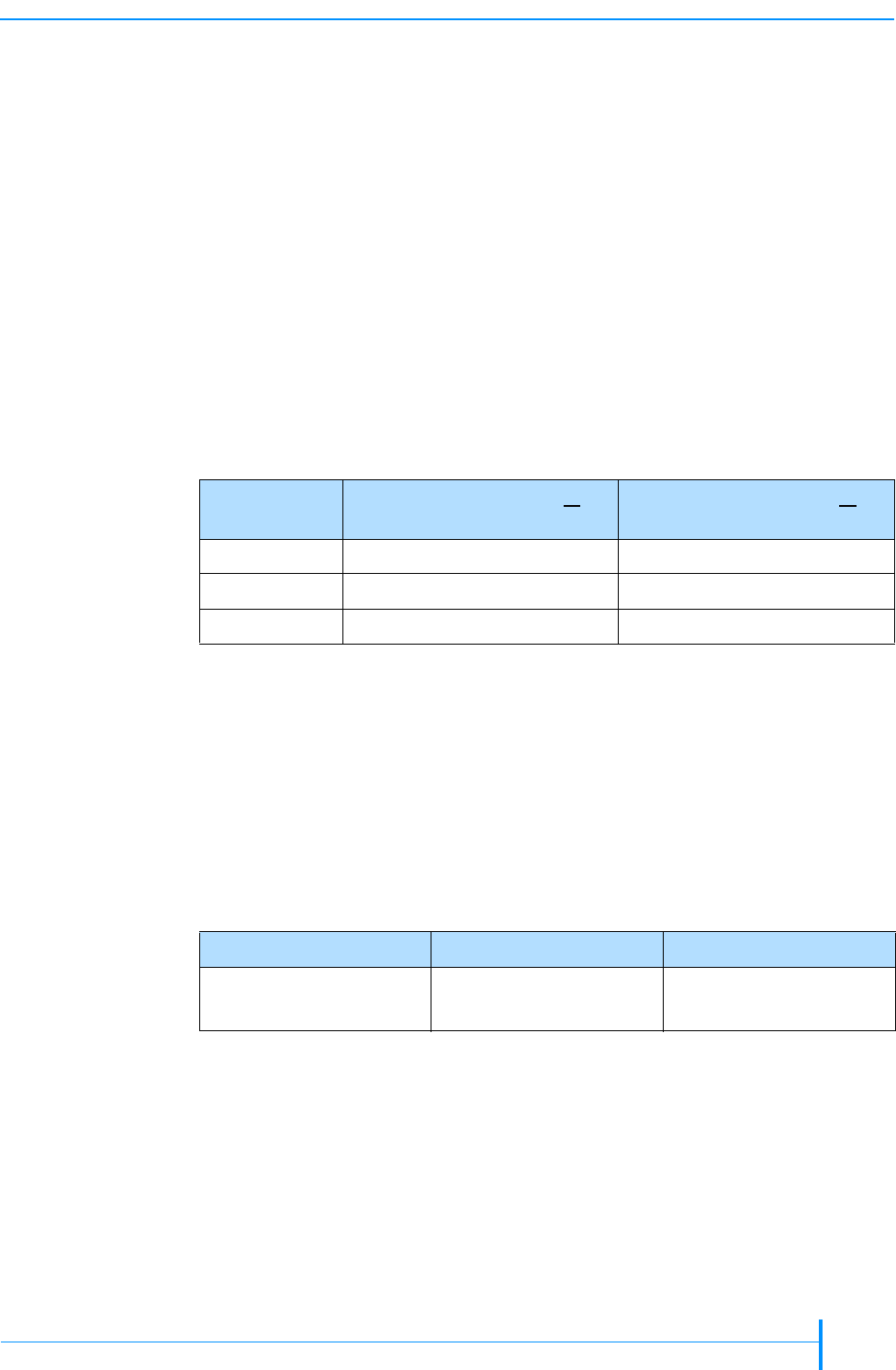

Table 7-17 Particulate contamination limits

Particle Size

(Microns)

Number of Particles >

Particle Size per Cubic Meter

Number of Particles >

Particle Size per Cubic Foot

0.1 8.8 x 10

7

2.5 x 10

6

0.5 3.5 x 10

7

1.0 x 10

6

5.0 2.5 x 10

7

7.0 x 10

6

Table 7-18 Shock specifications

Operating Nonoperating

a, b

a

The tape drive has been unpacked, but no power is applied.

b

Half-sine shock pulses are applied to each of the three orthogonal axes. (Three shocks at 60 g at a rate not

exceeding 1 shock per second. One shock at 50 g.)

Transportation

c

c

The tape drive is in its original shipping container.

5 g for 3 msec

d

6 g for 11msec

e

d

Half-sine, at a rate not exceeding 1 shock per second; 20 shocks applied to each of the three orthogonal

axes.

e

Half-sine, at a rate not exceeding 1 shock per every 3 seconds; 10 shocks applied to each of the three

orthogonal axes.

60 g for 3 msec

50 g for 11 msec

ISTA Procedure 2A