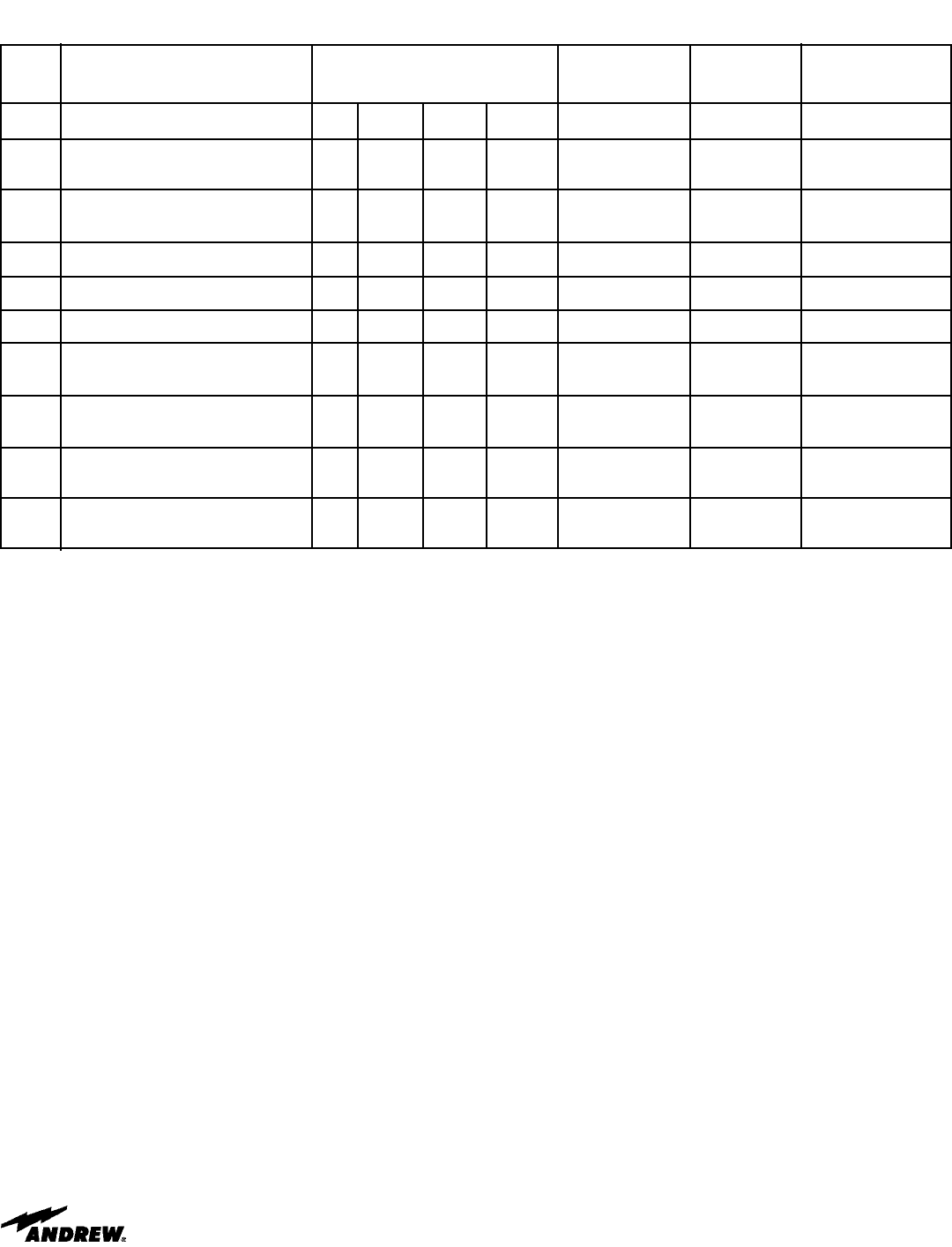

62

Preventive Maintenance

Lube Components Frequency Type Type No. of Lube

Point to be (Months) of of Points or

No. Lubricated 13612Service Lube Quantity

1. Elevation Jackscrew Housing X Pressure Fitting SHC32 1

2.

1

Elevation Jackscrew Gear Housing I* C** Pipe Plugs SHC624 10 Oz

Fill and Drain

3.

2

Elevation Drive Intermediate Gearbox I* C** Pipe Plugs SHC624 34 Oz.

Fill and Drain

4. Elevation Jackscrew Pivot Pin, upper X Pressure Fitting SHC32 1

5. Azimuth Jackscrew Pivot Pin, front X Pressure Fitting SHC32 1

6. Azimuth Jackscrew Housing X Pressure Fitting SHC32 2

7.

1

Azimuth Jackscrew Gear Housing I* C** Pipe Plugs SHC624 4 Oz.

Fill and Drain

8.

2

Azimuth Drive Intermediate Gearbox I* C** Pipe Plugs SHC624 34 Oz.

Fill and Drain

9. Polarization Drive Gear X Brush SHC32 Minimum Surface

Coverage

10. Feed Rotation Worm Gear X Pressure Fitting SHC32 2

Pillow Blocks

X = Lubricate I = Inspect C = Change

* Inspection requires checking for visible signs of oil leakage, draining replacing and adding oil to ensure appropriate oil

level requirements. Excessively dirty oil will require fresh oil replacement. If oil leakage is found to be excessive, refer to

appropriate troubleshooting information and perform applicable corrective action. Periodic inspection procedures can be

less frequent after first or second scheduled inspections.

** Initial oil change requirements include flushing gear boxes with a standard cleaning agent.

1 Type ‘HS’ and ‘STHS’ drives only. 10 oz. required for gearbox on Type ‘MS’ drives.

2 Type ‘HS’ and ‘STHS’ drives only.

Lubrication Chart