8.3 Wiring Precautions the Part which Matches the EMC Directives

8.3.2 Grounding the ground cable

8 - 16

1

OVERVIEW

2

SYSTEM

CONFIGURATION

3

PERFORMANCE

4

NAMES OF

THE PARTS AND

THEIR SETTINGS

5

ROUGH

PRE-OPERATION

PROCEDURE

6

HANDLING

7

MAINTENANCE AND

INSPECTION

8

EMC DIRECTIVE

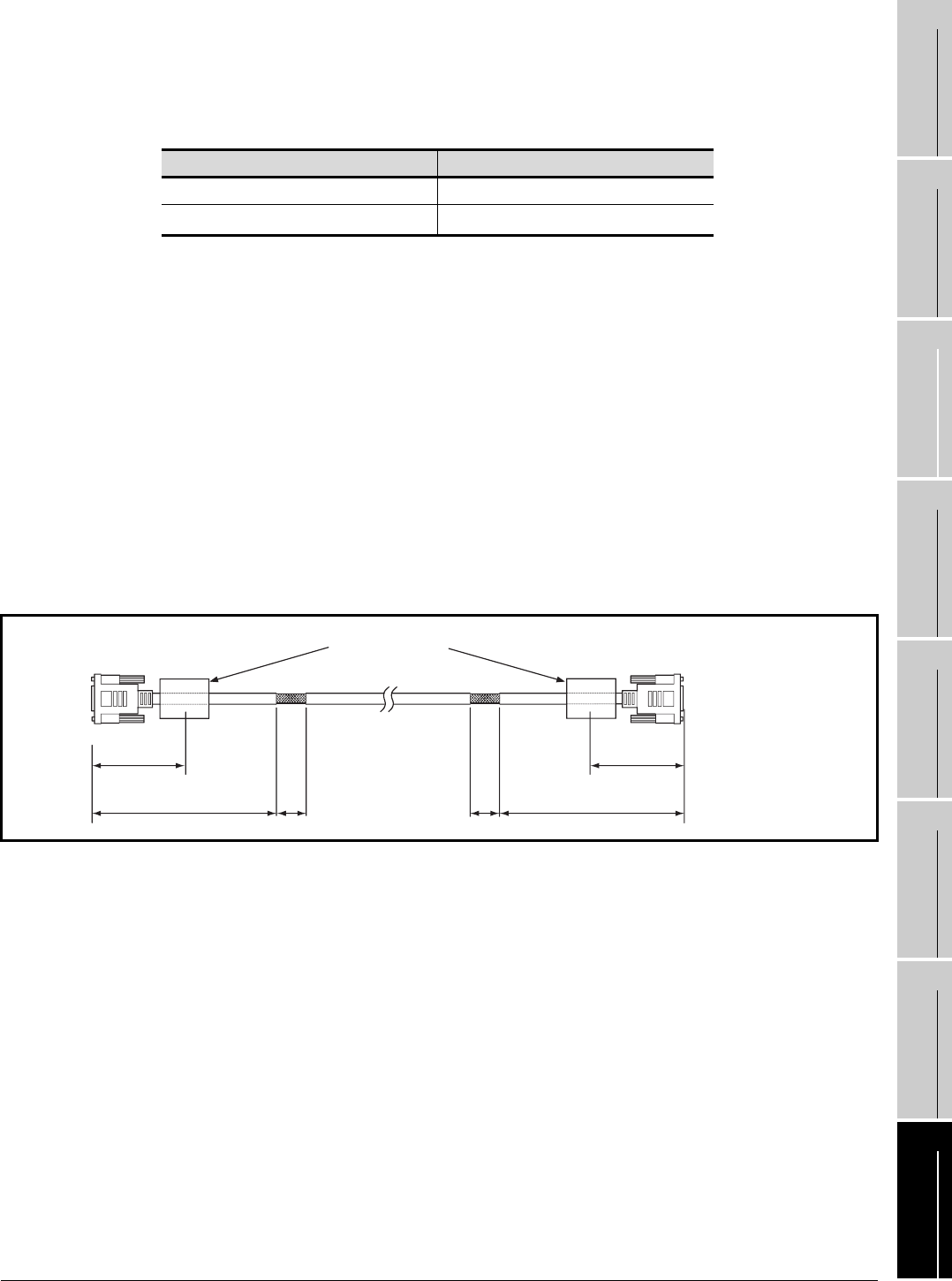

2) Precautions for manufacturing cable

• Make a twisted pair for each signal and SG.

• Connect the braided shield to the connector shell (both ends).

• The cable used for the Mitsubishi EMC Directive compatibility test had the following

specifications.

3) Connector (connector cover)

• GOT connector

Use the connector matching the following model for the GOT.

9-pin D-sub (male) inch screw type

manufactured by DDK

17JE-23090-27 (D3CC)

• Connector of computer link unit

Refer to the user’s manual of the serial communication, computer link module or PLC CPU

with computer link function.

4) Cable production method

• Peel the sheath (with the length shown below) at both ends of the cable, and expose the

shield braided wire for grounding.

• The cable must be 15m or shorter.

Item Specification

Cable type Twisted pair shield cable

Conductor section area (mm

2

)

0.2

130

(5.12)

130

(5.12)

GOT side

Within 230

(9.06)

Within 400

(15.75)

40

(1.57)

Unit: mm (inch)

Ferrite core

(ZCAT3035-1330)

Computer link module side

40

(1.57)