7.2 Daily Inspection

7 - 2

1

OVERVIEW

2

SYSTEM

CONFIGURATION

3

PERFORMANCE

4

NAMES OF

THE PARTS AND

THEIR SETTINGS

5

ROUGH

PRE-OPERATION

PROCEDURE

6

HANDLING

7

MAINTENANCE AND

INSPECTION

8

EMC DIRECTIVE

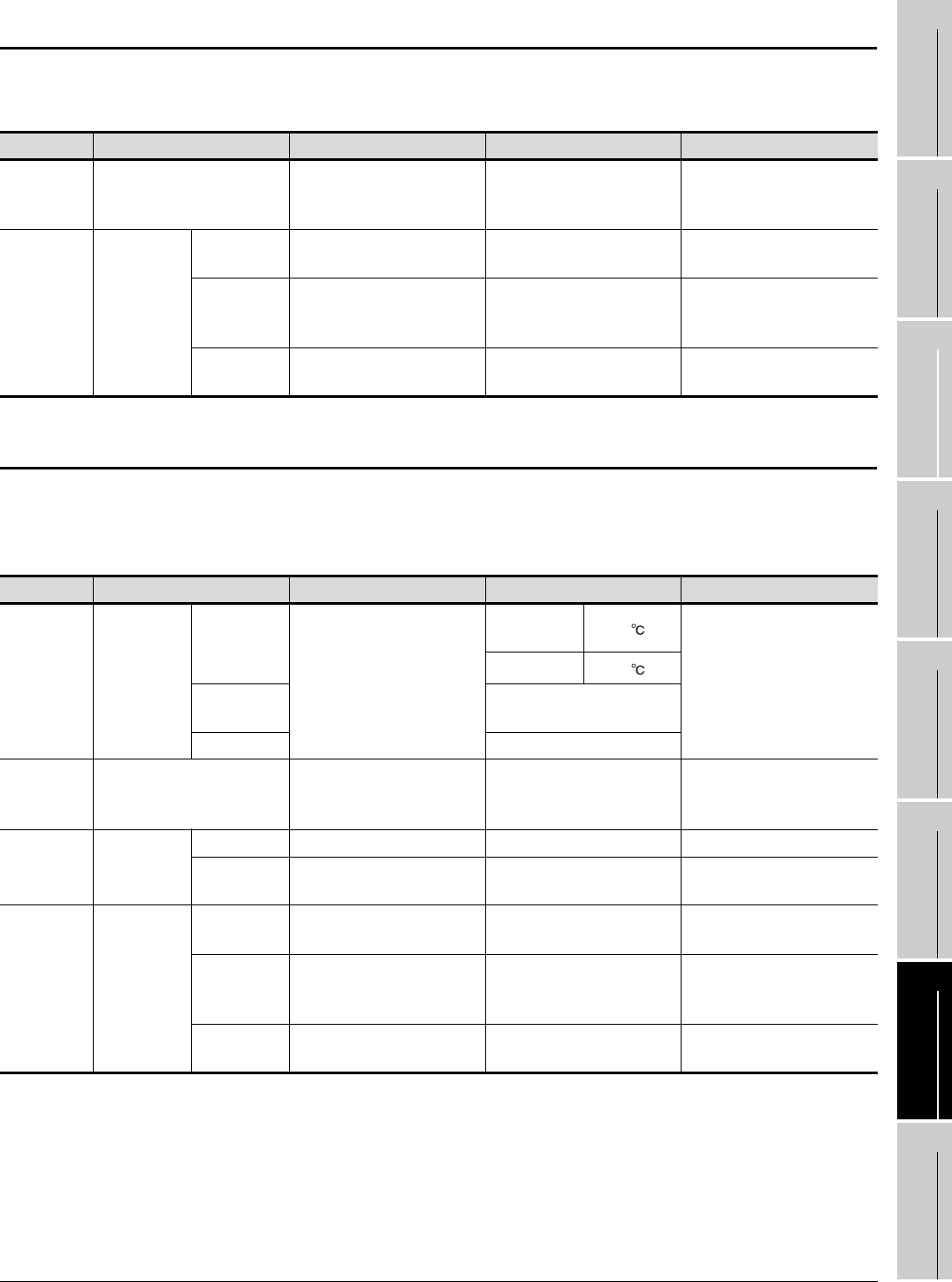

7.2 Daily Inspection

Daily inspection items are as follows.

7.3 Periodic Inspection

Inspection items to be checked once or twice in six months or one year are as follows.

The following inspection should also be performed when equipment has been moved or modified or the wir-

ing changed.

Number Inspection Item Inspection Method Criterion Action

1 Module mounting status

Check for loose mounting

screws and disconnected

cover

Securely mounted Retighten screws

2

Connection

status

Loose termi-

nal screws

Retighten screws with screw-

driver

Not loose Retighten terminal screws

Proximate

solderless ter-

minals

Visual check Proper intervals Correct

Loose con-

nectors

Visual check Not loose

Retighten connector fixing

screws

Number Inspection Item Inspection Method Criterion Action

1

Surrounding

environment

Ambient tem-

perature

Make measurement with ther-

mometer or hygrometer

Measure corrosive gas

Display sec-

tion

0 to 40

For use in enclosure, tempera-

ture inside enclosure is ambi-

ent temperature

Other portions

0 to 55

Ambient

humidity

10 to 90%RH

Atmosphere No corrosive gas

2 Power supply voltage check

24VDC

Measure voltage across termi-

nals

20.4DC to 26.4V Change supply power

3

Mounting sta-

tus

Looseness Move module Should be mounted firmly Retighten screws

Dirt, foreign

matter

Visual check No dirt, foreign matter sticking Remove, clean

4

Connection

status

Loose termi-

nal screws

Retighten screws with screw-

driver

Not loose Retighten terminal screws

Proximate

solderless ter-

minals

Visual check Proper intervals Correct

Loose con-

nectors

Visual check Not loose

Retighten connector fixing

screws