9 - 14

9.4 Troubleshooting in bus connection

9.4.2 Further locating error positions

9.4.2 Further locating error positions

If the function of the PLC cannot be recovered even when the module on which an error occurs is replaced

with a new one, the error may be caused by the effect from another module.

Disconnect the extension cables and bus connection cables in order from the modules starting from the

module located furthest from the operating position in the system, and check for the status of occurrence of

the error each time the cables are disconnected until the error does not occur.

The module or extension cables/bus-connection cables disconnected immediately before the error does not

occur are considered to cause the error.

Examples of the ways of further locating error positions are shown below.

Repeat the examples 1 and 2 above to locate error positions.

• When disconnecting the extension base units in order, use only an END

instruction for the sequence program, and any error resulting from the sequence

program will not occur, and the status of occurrence of errors will be obtained

easily.

• When the frequency of occurrence of an error is low, check the error by taking a

rather long time with the modules disconnected.

• The checks stated above are effective to locate a noise invading route when the

mis-operation is caused by noise.

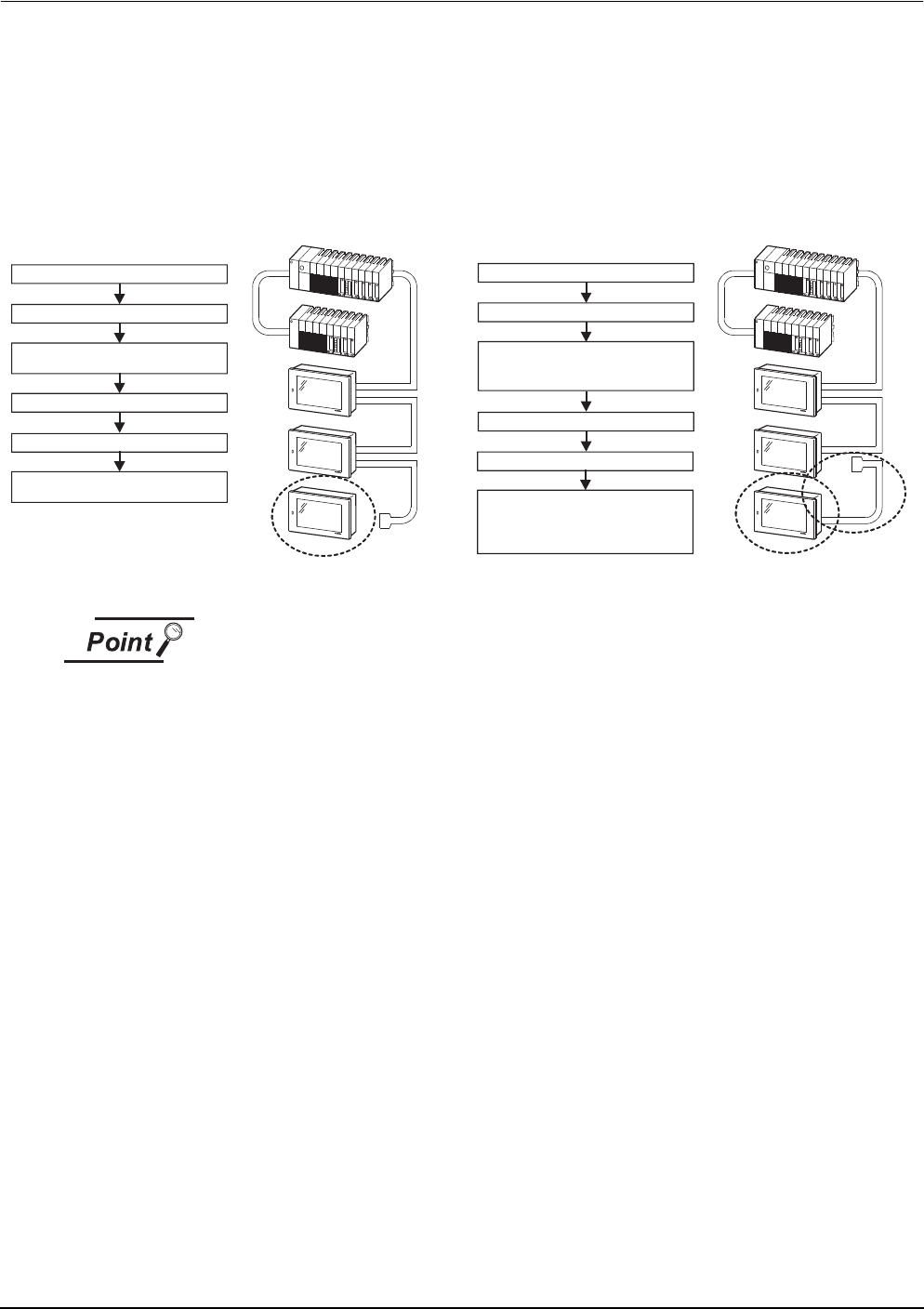

Disconnect the bus-connection cable

(OUT side) from the GOT located one

stage before the final stage.

Example 2:

Example 1:

Turn off the power of the GOT.

Turn off the power of the PLC CPU.

Disconnect the bus-connection cable

(IN side) from the final stage GOT.

Turn on the power of the PLC CPU.

Turn on the power of the GOT.

If an error does not occur, the final

stage GOT may be faulty.

Turn off the power of the GOT.

Turn off the power of the PLC CPU.

Turn on the power of the PLC CPU.

Turn on the power of the GOT.

If an error does not occur, the final

stage GOT and the bus-connection

cable before the final stage may be

faulty.