60 Model IFT9701 Transmitter Instruction Manual

Troubleshooting continued

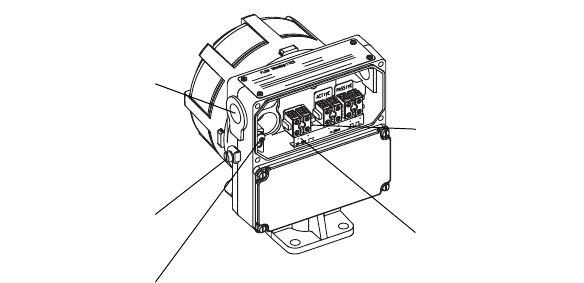

Figure 8-2 Power supply connections

7. Make sure the power cable is not installed in the same conduit or cable tray as output wiring.

8. Make sure the meter is properly grounded. If national standards are not in effect, adhere to this

standard:

• For grounding, use copper wire, 14 AWG (2,5 mm²) or larger wire size.

• Either the internal ground screw or external case ground screw may be used as required by

local policy or code.

• Keep all ground leads as short as possible.

• Flowmeter must be grounded with less than 1 ohm impedance.

• Connect power-supply ground directly to earth.

The flowmeter does not have replaceable fuses for the power supply.

8.5 Wiring

For detailed wiring instructions, refer to Chapters 3 and 4.

Wiring problems are often incorrectly diagnosed as a faulty sensor. At initial startup of the

transmitter, always check the following:

1. Proper cabling, and use of shielded pairs

2. Proper wire termination

• Wires on correct terminals.

• Wires making good connections with the terminal strip.

• Wires making good connections at the receiving device.

• Wires making good connections at the sensor terminals. Table 8-3 lists terminal

designations for Micro Motion sensors.

¾-inch NPT or M20

conduit opening

Seal opening with

conduit seal or

cable gland

Power supply

terminals

Internal ground

screw

External case

ground screw

Voltage label

Match power supply to

voltage specified on label