Configuration with Communicator TroubleshootingConfiguration with ProLink IIFlowmeter Startup

Model IFT9701 Transmitter Instruction Manual 45

Chapter 7

Configuration with ProLink II Software

7.1 Configuration overview

You may use the Micro Motion ProLink II software, installed on a personal computer, to set up the

basic configuration and zero the flowmeter. See the ProLink II manual or on-line help for additional

information.

Configuration parameters include such items as flow cutoff and damping values, flow direction, and

milliamp output scaling. If requested at time of order, the meter is configured at the factory according

to customer specifications. For factory-calibrated sensors, field calibration is not normally needed nor

recommended. Basic configuration is described in Section 7.2.1.

Calibration accounts for performance variations in individual meters and peripheral devices.

Calibration procedures include autozeroing and flow calibration. Zeroing is required upon initial

flowmeter startup (see Section 4.3); flow calibration may or may not be required. For information on

calibration procedures using ProLink II, see Section 7.3.

Characterization is the process of using a communication device to enter calibration factors for flow,

density, and temperature directly into flowmeter memory, instead of performing field calibration

procedures. Calibration factors can be found on the flowmeter serial number tag and on the certificate

that is shipped with the meter. For information on characterization using ProLink II, see Section 7.4.

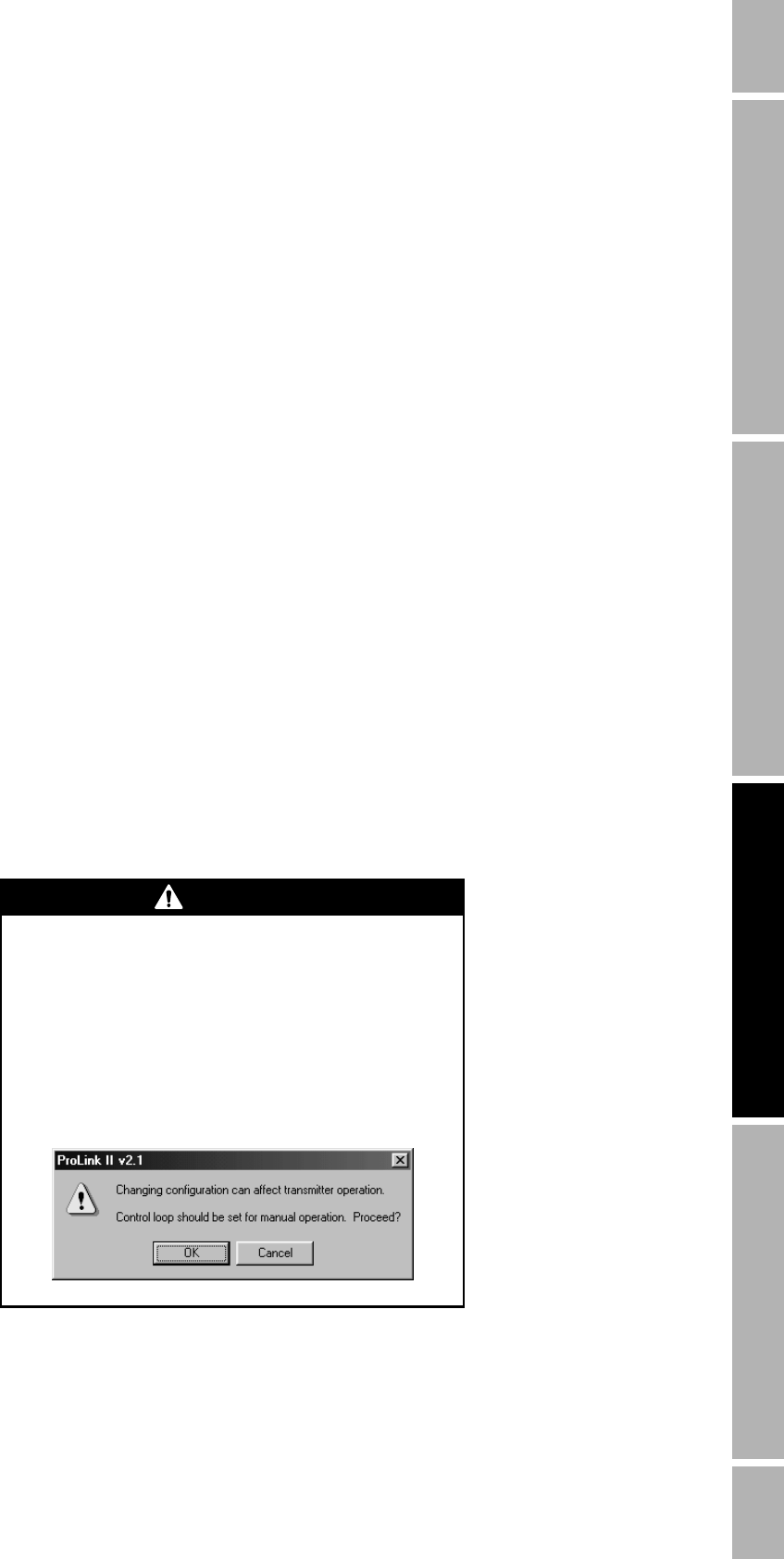

Set control devices for manual operation during flowmeter configuration.

CAUTION

Failure to set control devices for manual operation

during configuration will affect flowmeter

output

signals.

Before using the Configuration window, set process

control devices for manual operation.

Whenever a display such as the one depicted below

appears, isolate the flowmeter from devices that use

flowmeter outputs for process control, then choose Yes.