Reference Manual

00809-0100-4696, Rev AA

September 2004

F-3

Rosemount 848L

Double Block and Bleed

If the valve absolutely must not leak into the process, then two valves are put

in series and the short pipe between them is vented (bled) to an appropriate

place. The bleed valve must be shut before the main valves can be opened,

and the main valves must both be closed before the bleed valve can be

opened.

Motorized Valve

The actuator is a reversible motor that turns a lead screw that moves the

valve stem. Two confirms are required because the motor is only free to turn

while the valve stem is travelling. Outputs are required for the Forward and

Reverse motor directions. If a big motor-driven valve takes a minute to

change position, that’s a long time to find out that it didn’t move. The crack

time is a period of time in which the previously closed contact must open, to

confirm that the actuator is moving and the valve is not stuck or powerless.

Heat Exchange Medium Selection

Batch heat exchangers have to use different media to heat and cool. If the

media are compatible, like steam and chilled water, then a simple four valve

manifold can handle the selection. The four valves are independent because

it is necessary to drain one medium from the exchanger before using the

other. There are many variations on this theme, for incompatible media or

more than two choices.

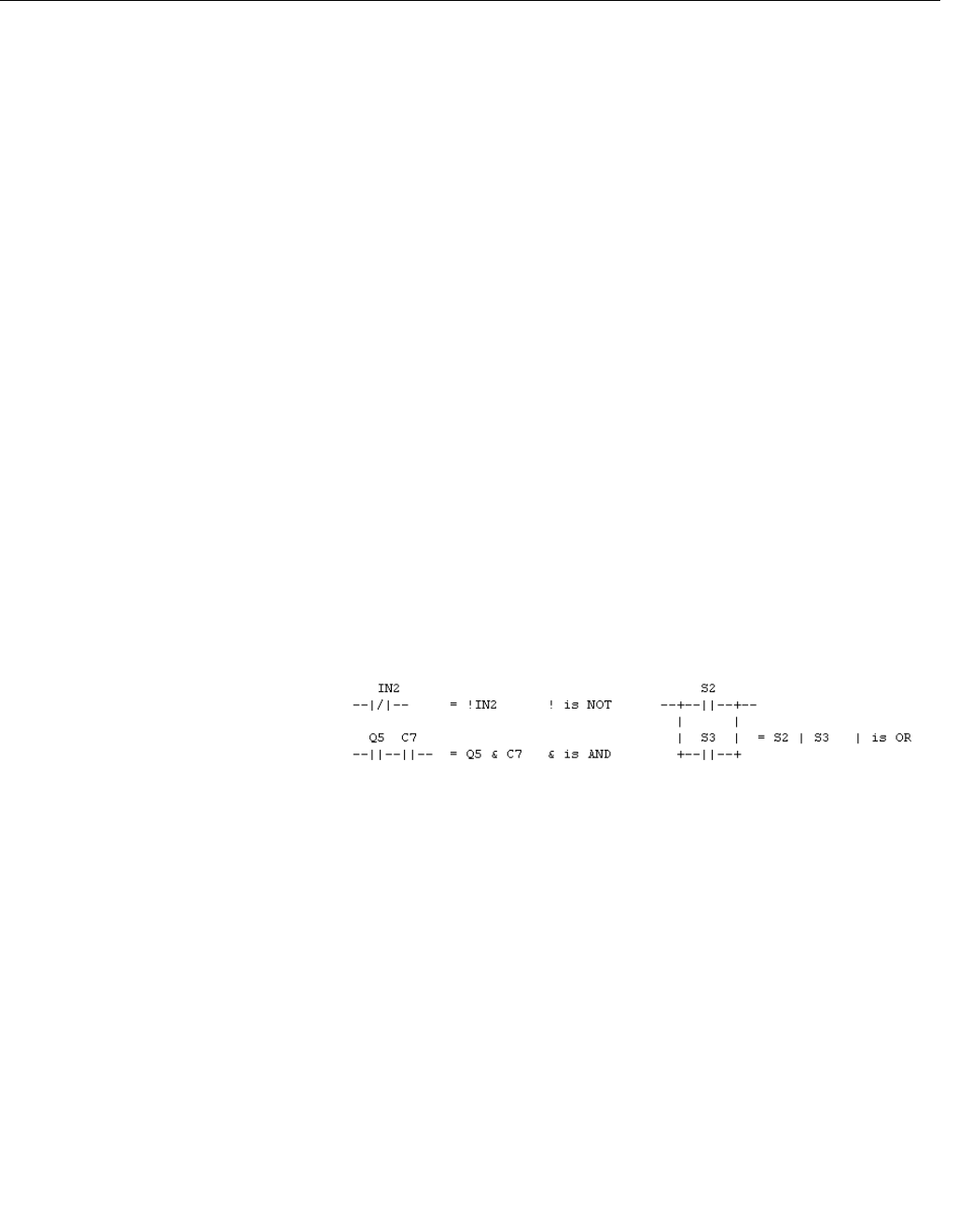

Boolean Expressions The motor control descriptions used ladder logic. Another method that takes

less room on the back of an envelope is the Boolean expression. The

following is a comparison of Boolean and ladder operators (math operators

are +,-,*,/). Only three operators are used in the examples:

Functions are the same as 848L functions. The examples use TON, TOF and

TP.

Basic Valve Control Since very few applications exist for local valve control that are more than a

simple toggle switch (electric or pneumatic), all examples use a DO block to

take a command from Fieldbus. The DO point is on for open and off for close

in all cases.