3

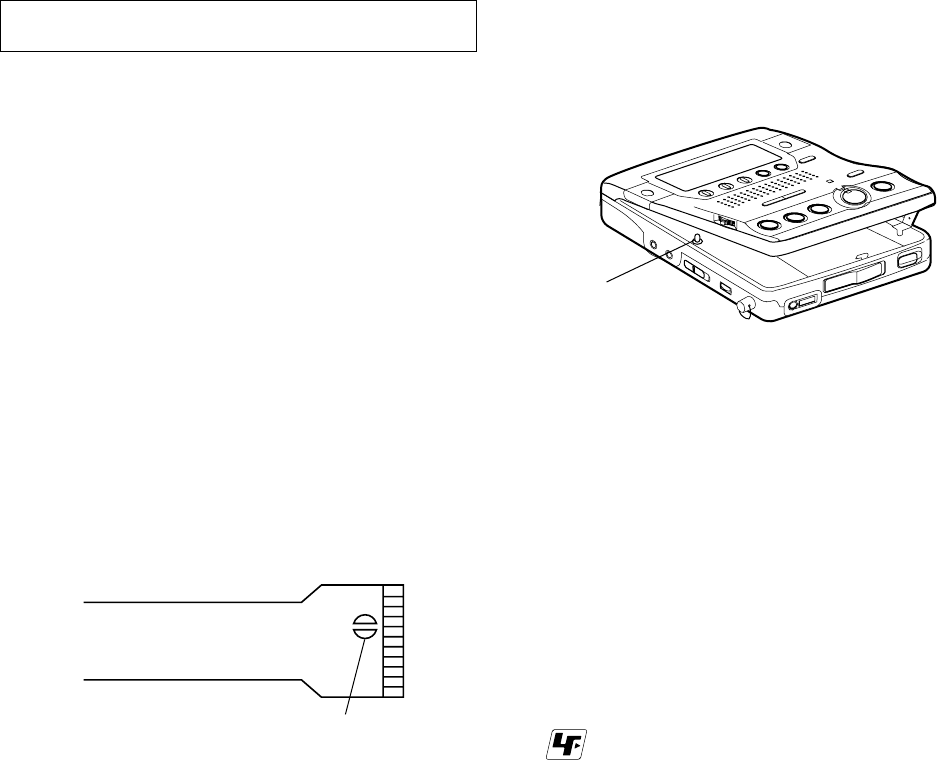

MZ-B100

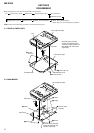

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

Never look into the laser diode emission from right above when

checking it for adjustment. It is feared that you will lose your sight.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

(LCX-4R)

The laser diode in the optical pick-up block may suffer electrostatic

break-down easily. When handling it, perform soldering

bridge to the laser-tap on the flexible board. Also perform measures

against electrostatic break-down sufficiently before the operation.

The flexible board is easily damaged and should be handled with

care.

OPTICAL PICK-UP FLEXIBLE BOARD

SECTION 1

SERVICING NOTES

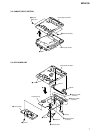

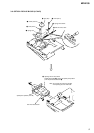

• When repairing this device with the power on, if you remove the

MAIN board or open the upper panel assy, this device stops work-

ing.

In this case, you can work without the device stopping by fasten-

ing the hook of the open/close detect switch (S804).

• This set is designed to perform automatic adjustment for each

adjustment and write its value to EEPROM. Therefore, when

EEPROM (IC802) has been replaced in service, be sure to per-

form automatic adjustment and write resultant values to the new

EEPROM.

(Refer to Section 5 Electrical Adjustment. (page 19))

• Replacement of CXD 2671-209GA (IC801) used in this set re-

quires a special tool.

laser-ta

p

S804

z

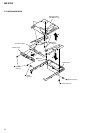

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the lead-

free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.