8

9

TIP: If the bottom of the array ends up being

too far downstage during assembly, have

stagehands breast it upstage until assembly

is complete and it is own to its nal trim

position.

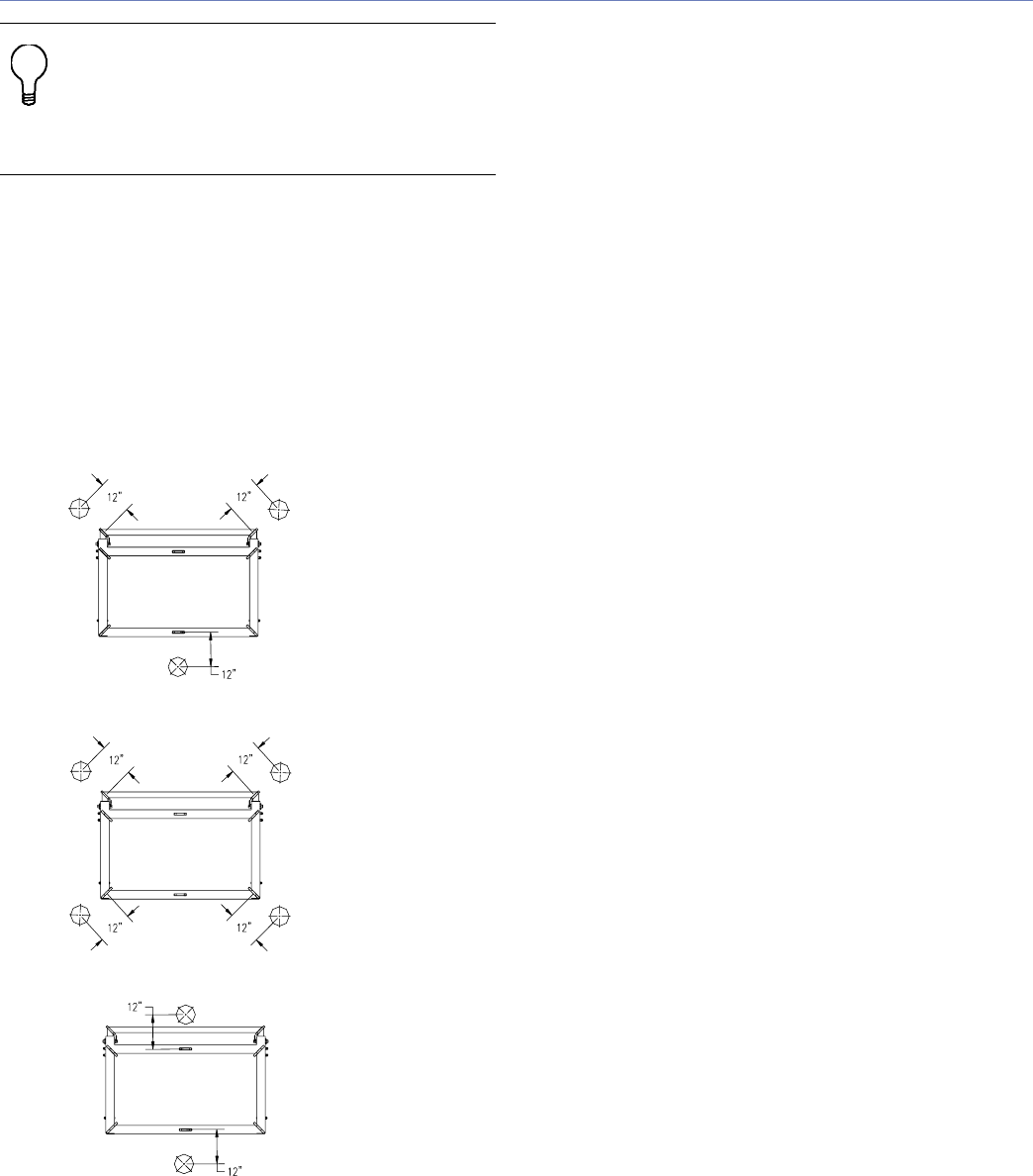

5. It is often necessary to increase the stability of an

array in venues with very high structural steel from

which the array is suspended. The rigging points

can be located a small distance, that is, 6 inches

(152.4 mm) diagonally, from the MTG-3D Top Grid

dimensions for a four-motor conguration. For a two-

motor conguration, the rigging points can be located

a small distance outside of the MTG-3D Top Grid’s

depth, as shown in Figure 9.

Structural Steel Rigging Point

Structural Steel Rigging Point

6" to 12" Outside of Rigging Frame

6" to 12" Outside of Rigging Frame

Figure 9. Example of wide rigging

In the congurations shown in Figure 9, the motors will be

outside of the actual MTG-3D Top Grid dimensions. The

technician will need to pull the motors in to attach them

to the MTG-3D Top Grid. When the array is own into

position, it will nd its own center of gravity between the

motors. In windy conditions, this will also reduce swaying.

This method minimizes any chance of a cable pic turning

the array. If three or four motors are used and the array is

slightly off its ideal horizontal angle, individual motors can

then be used to turn the array once it is close to its nal

trimmed position.

ARRAY ASSEMBLY AND

ANGLE ADJUSTMENT

You will need the following items for assembling the array

and adjusting the angle:

Quick release pins (QRPs)

Cable assembly

Alignment block (optional)

Vertical angle conguration

STARTING ARRAY ASSEMBLY

After determining that you have all the necessary

equipment and tools, proceed as follows:

1. Choose the appropriate motor points for the rigger to

prepare the ground rigging of a hanging conguration,

selecting from the options shown in “Appendix A

— Congurations and Load Ratings.”

2. Once the points have been rigged, check for accuracy

and ensure that the climbing riggers have nished all

the points for the array before applying any weight to

these points.

3. Apply power to the motors, checking for correct

electrical phase (chain movement direction — see

Figure 10). Change phase if necessary.