4. Allow the connection to cool undisturbed.

Remember that the connection is made by the solder,

not by mechanically attaching the wire to the terminal.

Usually the wire is looped through the lug and crimped in

place, but some prefer to just place it through the hole and

rely on the stiffness of the wire to hold it while soldering.

Eyelet connections, of course, are handled this way.

Good solder connections are essential for trouble-free,

noise-free operation.

A good

solder joint does not require

much solder around the conductors. Never “butter” par-

tially melted solder on the joint, as it is useless. A good

connection looks smooth and bright because the solder

flows into every crevice when the parts are hot enough.

The iron must have a bright, shiny tip to transfer heat eas-

ily to the junction. That’s why the damp sponge should be

used frequently to wipe the tip, and occasionally you must

add a small amount of solder to the tip, too. If a connection

is difficult to heat, “wet” the tip with a small blob of solder

to provide a bigger contact surface to the joint. Once the

solder flows around the conductors, any movement must

be avoided for a few

seconds

to allow a good bond. When

cool, check the connection by wiggling the wire. If in

doubt, or if the connection is not shiny, re-heat the joint.

Excess solder may be removed from a connection by heat-

ing it and allowing the solder to flow onto the iron, which is

then wiped on the sponge.

ALL SOLDER USED MUST BE ROSIN CORE

Never use acid core solder or any separate flux in elec-

tronic work. Silver solder is also not suitable. If in doubt

about unmarked solder, always obtain a fresh supply of

rosin core solder. We recommend

60/40

for easiest use. Do

not confuse it with 40160, which is harder to melt.

The general procedure is to use a hot iron for a short time

to heat a connection, then add solder with the iron still in

contact. Remove the solder once it flows, and then remove

the iron. A cooler iron applied for a longer time is more

likely to damage components, or lift the copper circuit pat-

tern from the boards. A break in the etched circuit can be

mended by simply soldering a small piece of wire across it.

D

O

not allow much build-up of solder on the tip of the iron,

or it may fall into adjacent circuitry.

When soldering to an eyelet or hole on the board, insert

the wire from the components side, and apply the iron to

the bottom, leaving some bare wire exposed so that you

can see that the eyelet is then filled with solder for a secure

bond. A round wooden toothpick is suggested so that you

can heat and clear an eyelet of solder if it hinders your in-

serting the wire. Some builders prefer to clear every eyelet

first with a touch

of the

iron and toothpick. Others connect

the lead by bringing it up to the center of the eyelet on top

of the board, applying the iron from the bottom of the

board, and pushing the lead in as the solder in the eyelet

melts. If the wire has first been “tinned,” usually no addi-

tional solder is necessary, but it is a good practice to push

the wire through, and then back it up a bit, to be sure solder

fills the eyelet. On the bottom of the board, make certain a

bright, shiny flow is evident from the wire onto the circuit

pattern on the board.

"Tinn

ning”

refers to the process of applyinga light

coat-

ing ofsolder to the bared wire end. This keeps all the

strands secured, and also makes a good connection easier.

Simply touch the wire with the iron for a couple seconds,

and apply solder. Allow the excess to flow away onto the

iron. When properly done, the wire is uniformly bright,

and no larger than before. The hookup wire supplied with

this kit does not normally need tinning, for it is pre-tinned.

Wiring the Kit

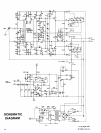

If any components are unfamiliar to you, checking the

pictorial diagram should quickly identify them. Or, the

quantities, and the process of elimination as you check the

parts list, will help. The pictorial diagram is necessarily

distorted to some extent for clarity, so that you can trace

every wire in a single overall view for verification as you

work. You may wish to check off on the diagram as you

solder each location.

To

“prepare” a wire means to cut the designated length

from the coil of that color, and strip about

l/4”

of insulation

from each

end. The

wire supplied in the kit is #18 and

#22,

so you can set adjustable wire-strippers accordingly. The

transformer leads are

#18,

and the line cord is

#16.

Be

careful that you do not nick the wire when you strip

it (that

can happen more easily if you do not use wire strippers) for

that weakens it. The wire supplied in this kit is “bonded

stranded,” which provides exceptional flexibility with re-

sistance to breakage for easier use.

Whenever a connection is to be soldered, the instruc-

tions will so state, or indicate by the symbol (S). If more

than one wire is to be soldered to the same point, they will

be indicated by (S-2), (S-4), etc. If soldering is not called

for, other connections have yet to be made to that termi-

nal. They would be more difficult if the connection was al-

ready soldered. Every connection in the kit will be sol-

dered when it is complete. After soldering a connection, it

is best to clip off any excess lead length to minimize the

possibility of a short circuit (as on switch lugs, where ter-

minals are very close together), and for neatness.

Be sure that uninsulated wires ca

terminals or the chassis metalwork.

nnott

touch adjacent

The symbol

(#)

indicates a connection is to be made to

that point. When a lug number is specified without

(#),

it is

simply a locating reference.

When the instructions call for twisting two or three

wires together, the length of wire indicated anticipates a

fairly tight, uniform twist by hand, of three full turns every

two inches. If you find the wires too short, loosening the

twist will gain some needed length.

Handle

the

circuit boards carefully. They represent a

major part of the kit cost. Stand-up components,

such as

transistors, should be checked when you install the

mod-

ule, to be sure all leads are separated, and that the large

electrolytic capacitors have not broken loose from the

board.

Take the time to be accurate and neat, and you can be

sure that your completed amplifier will meet the per-

formance of a factory assembled unit, and can continue to

perform properly for years to come. Check your work, and

make sure the entire step has been completed before plac-

ing a check mark in the space provided, and continuing on

to the next step.