34-ST-03-64

Page 4

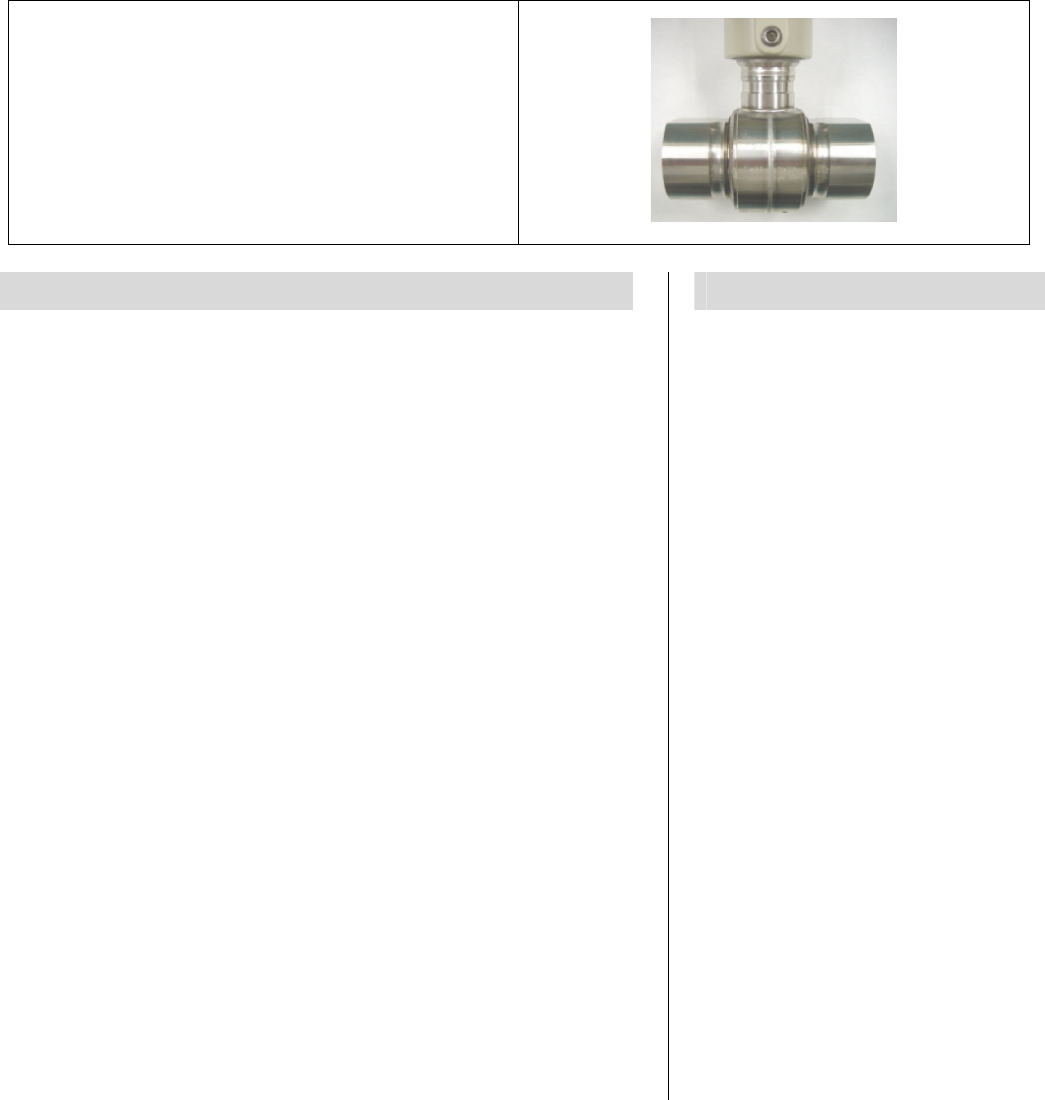

Figure 12 - Welded Meter Body for All-Welded

Remote Seal Solution. The welded ST 3000 meter

body is an important part of an All-Welded Remote

Seal Solution, which is commonly used in Vacuum

applications.

Figure 12

Description Features

The ST 3000 transmitter can replace any 4 to 20 mA output

transmitter in use today and operates over a standard two-wire

system.

The measuring means is a piezoresistive sensor, which actually

contains three sensors in one. It contains a differential pressure

sensor, a temperature sensor, and a static pressure sensor.

Microprocessor-based electronics provide higher span-turndown

ratio, improved temperature and pressure compensation, and

improved accuracy.

The transmitter’s meter body and electronics housing resist shock,

vibration, corrosion, and moisture. The electronics housing contains

a compartment for the single-board electronics, which is isolated

from an integral junction box. The single-board electronics is

replaceable and interchangeable with any other ST 3000 Series 100

or Series 900 model transmitter.

Like other Honeywell transmitters, the ST 3000 features two-way

communication and configuration capability between the operator

and the transmitter through several Honeywell field-rated portable

configuration devices, including the Smart Field Communicator

(SFC) and the Multiple Communication Configurator (MC ToolKit).

While both are made for in-field use, the MC Toolkit also can be

ordered for use in intrinsically safe environments.

The SCT 3000 Smartline

®

Configuration Toolkit provides an easy

way to configure instruments using a personal computer. The toolkit

enables configuration of devices before shipping or installation. The

SCT 3000 can operate in the offline mode to configure an unlimited

number of devices. The database can then be loaded down-line

during commissioning.

• Choice of linear or square root

output conformity is a simple

configuration selection.

• Direct digital integration with

Experion PKS and other control

systems provides local

measurement accuracy to the

system level without adding

typical A/D and D/A converter

inaccuracies.

• Unique piezoresistive sensor

automatically compensates input

for temperature and static

pressure. Added “smart”

features include configuring

lower and upper range values,

simulating accurate analog

output, and selecting

preprogrammed engineering

units for display.

• Smart transmitter capabilities

with local or remote interfacing

means significant manpower

efficiency improvements in

commissioning, start-up, and

ongoing maintenance functions.