34-ST-03-64

Page 11

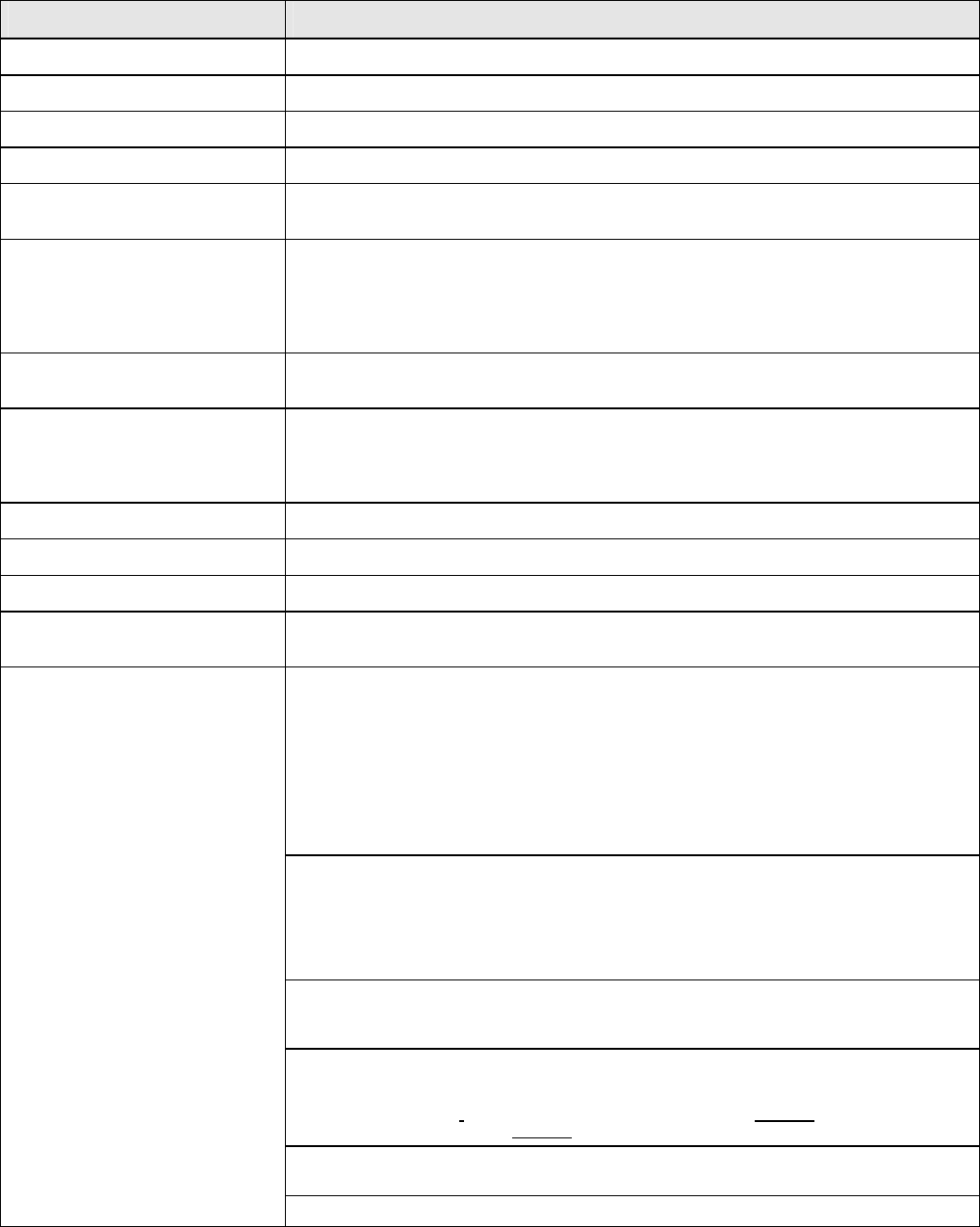

Physical and Approval Bodies

Parameter Description

Process Interface

See Model Selection Guide for Material Options for desired seal type.

Seal Barrier Diaphragm

316L Stainless Steel, Monel, Hastelloy C, Tantalum

Seal Gasket Materials

Klinger C-4401 (non-asbestos) Grafoil Teflon Gylon 3510

Mounting Bracket

Carbon Steel (Zinc-Chromate plated) or Stainless Steel.

Fill Fluid (Meter Body)

Silicone (DC 200) S.G. @ 25°C = 0.94

CTFE (Chlorotrifluoroethylene) S.G. @ 25°C = 1.89

Fill Fluid (Secondary)

Silicone (DC 200) S.G. @ 25°C = 0.94

CTFE (Chlorotrifluoroethylene) S.G. @ 25°C = 1.89

Silicone (DC 704) S.G. @ 25°C = 1.07

NEOBEE M-20 S.G. @ 25°C = 0.90

Syltherm 800 S.G. @ 25°C = 0.93

Electronic Housing

Epoxy-Polyester hybrid paint. Low copper-aluminum alloy. Meets NEMA 4X (watertight)

and NEMA 7 (explosion proof). Stainless steel optional.

Capillary Tubing

Armored Stainless Steel or PVC Coated Armored Stainless Steel.

Length: 5, 10, 15, 20, 25, and 35 feet (1.5, 3, 4.6, 6.1, 7.5, and 10.7 meters).

A 2 inch (51 millimeter) S.S. close-coupled nipple is also available. See Model Selection

Guide. Refer to Figure 14 for guide to maximum capillary length vs. diaphragm diameter.

Wiring

Accepts up to 16 AWG (1.5 mm diameter).

Mounting

See Figure 17.

Dimensions Transmitter: See Figures 20a and 20b. Seal: See Figures 21 through 31.

Net Weight

Transmitter:

15.4 pounds (7 Kg). Total weight is dependent on seal type and capillary

length.

Approval Bodies

Factory Mutual

Explosion Proof: Approved as Explosion Proof for Class I, Division 1, Groups A, B,

C, D locations,

Dust Ignition Proof: Approved as Dust Ignition Proof for Class II, III, Division 1,

Groups E, F, G locations,

Intrincically Safe: Approved as Intrinsically Safe for for Class I, II, III, Division 1,

Groups A, B, C, D, E, F, G locations.

Nonincendive: Approved as Nonincendive for Class I, Division 2, Groups A, B, C, D

locations.

CSA

Explosion Proof:

Approved as Explosion Proof for Class I, Division 1, Groups B, C,

D locations,

Dust Ignition Proof: Approved as Dust Ignition Proof for Class II, III, Division 1,

Groups E, F, G locations,

Intrincically Safe: Approved as Intrinsically Safe for Class I, II, III, Division 1, Groups

A, B, C, D, E, F, G locations.

Canadian Registration

Number (CRN)

All ST 3000 model designs, except SATG19L, STG99L, STG170 and STG180 have

been registered in all provinces and territories in Canada and are marked

CRN:0F8914.5c.

ATEX

Intrinsically Safe, Zone 0/1: EEx ia IIC T4, T5, T6

Flameproof/Zone 1: EEx d IIC T5, T6 (enclosure IP 66/67)

Non-Sparking, Zone 2: EEx nA, IIC T6 (enclosure IP 66/67)

Multiple Markings:

Ex II 1 G: EEx ia IIC T4, T5, T6, Ex II 2 G: EExd IIC T5, T6

Ex II 3 G

: EEx nA, IIC T6 (Honeywell) (enclosure IP 66/67)

SA (Australian)

Intrinsically Safe:

EX ia IIC T4

Non-Sparking: Ex n IIC T6 (T4 with SM option)

INMETRO (Brazil) Flame-Proof, Zone 1: EX d IIC T5