– 3 –

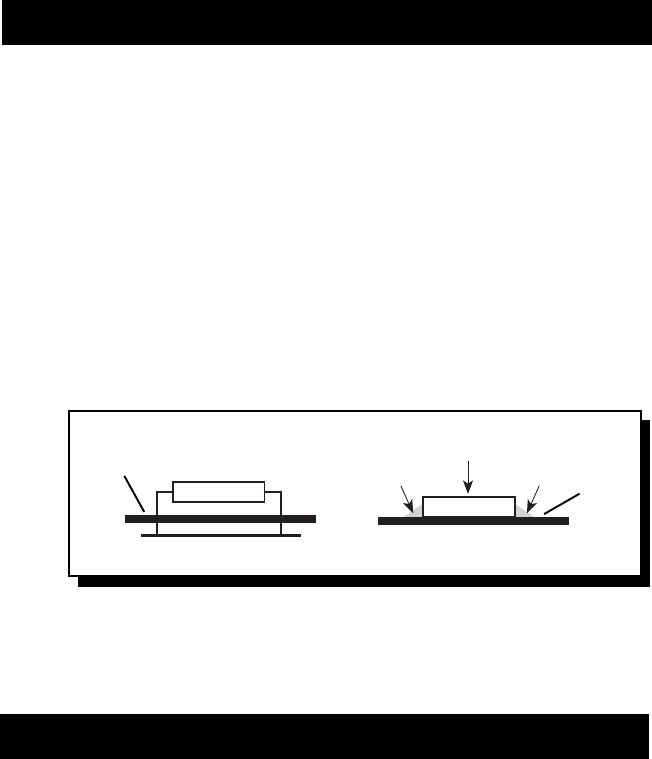

◆ DSM (Discrete Surface Mount) Technology

The

DSM

(Discrete Surface Mount) manufacturing process combines

the advantages of both discrete components and integrated circuitry.

Rockford Fosgate is the only American amplifier manufacturer to have

invested millions into this process. DSM components differ from

conventional discrete components in different ways. They are more

compact, more rugged, and they efficiently dissipate generated heat.

Using them wherever appropriate allows the advantages associated

with discrete circuitry to be retained while also providing room for

both highly advanced processing features and generous PC board

copper paths where needed. Their short lead-out structures allow

maximum audio performance and highest signal-to-noise ratios to be

obtained in amplifiers of desirable package size without resorting to

“amplifier-on-a-chip” shortcuts. These advantages are shown below

in Figure 1.

Figure 1

THE RESULT: Fewer connections, improved reliability, shorter signal

paths, superior signal-to-noise ratio and awesome sonic performance.

Solder

Solder

Component

Thru-Hole Surface Mount

PC

Board

PC

Board

◆ NOMAD (NOn-Multiplying Advanced Decision)

All Rockford Fosgate amplifiers use an

analog computer process

to

maximize safe output power under all operating conditions. The

innovative

NOMAD

(NOn-Multiplying Advanced Decision) system

is the most sophisticated version of this technique ever used, bringing

previously unavailable levels of accuracy, stability, temperature

immunity and reliability to this critical process. NOMAD makes

advanced decisions based on device voltages to precisely control the

awesome levels of current available in the output MOSFETs to safe

values – but only when absolutely needed.

THE RESULT: Extremely fast protection system that always protects

the amplifier and never degrades the sound.