34

Step 3

With the first gate in the desired open position. Program the open limit setting by setting the number 4 DIP switch on the

DUAL MODES switches to the OFF position (if the MASTER gate opened first) or the ON position (if the SLAVE gate

opened first) then PRESS & HOLD the “SET LIMIT" button on the control board for 5 seconds.

Step 4

Press the transmitter button and allow the gates to return to the closed position. YOUR FIRST GATE’S OPEN POSITION

LIMIT IS NOW PROGRAMMED.

Step 5

Activate your openers again by pressing the entry transmitter

button. Your gates should now be moving from the closed positions

toward their open positions. The first gate will stop at the spot you

just programmed and the second gate will continue to open until

you press the transmitter button again. Press the transmitter button

when the second gate reaches the desired open position. This step

may be repeated until desired open position is achieved. Once the

desired OPEN position has been achieved, proceed to step 6.

Step 6

With the second gate in the desired open position. Program the

open limit setting by setting the number 4 DIP switch on the

DUAL MODES switches to the ON position (if the MASTER gate

opened first) or the OFF position (if the SLAVE gate opened first)

then PRESS & HOLD the “SET LIMIT" button on the control

board for 5 seconds.

Step 7

Press the transmitter button and allow the gates to return to the closed position. BOTH YOUR MASTER AND SLAVE

GATE’S OPEN POSITION LIMITS ARE NOW PROGRAMMED.

TESTING YOUR OPEN LIMIT SETTING:

Press your entry transmitter and allow your gates to open. If OPEN positions are not correct or need to be changed, you will

need to CLEAR your OPEN LIMIT settings and follow steps one (1) to seven (7) again.

CLEARING THE PROGRAMMED OPEN LIMIT SETTING:

If you make a mistake and set the limit at the wrong position – press your transmitter to return the gates to their closed

positions, then press and hold the "SET LIMIT" button for 10 seconds. This will clear the memory for the open limit

positions. Follow steps one (1) to seven (7) again.

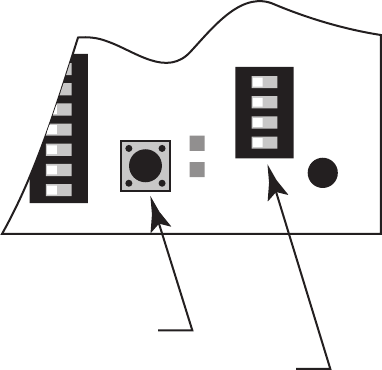

1

ON

2 3 4

DUAL

MODES

ON

OFF

1 2 3 4

ON

6 7

SET

LIMIT

ON

OFF

1 2 3 4 5 6 7

Set Limit Button

Dual Mode DIP Switches

• On all gates weighing 250 lb. or more, routinely grease the ball bearing hinges at least 4 times a year; more

frequently if the gates are near a coastal area.

• Keeping a few mothballs in the control box will discourage insects from entering it and damaging the control

board.

• Clean the push-pull tube with a soft, dry cloth and apply silicone spray to it at least once per month.

• While oxidation is a normal part of weathering of equipment that is exposed to the elements, we recommend

you apply silicone spray the front and rear mounts to minimize this effect.

Maintenance