Reference Manual

00809-0100-4514, Rev BA

January 2008

Rosemount 1154

3-4

Material

• Wire: 22-gauge tinned solid copper – Fed Spec QQW343, ASTM B33

• Solder: 60% tin, 40% lead (60/40) – Fed Spec QQ-S-571

• Flux: MIL F 14256, Type A, Fed Spec QQ-S-571 Type RA

Method

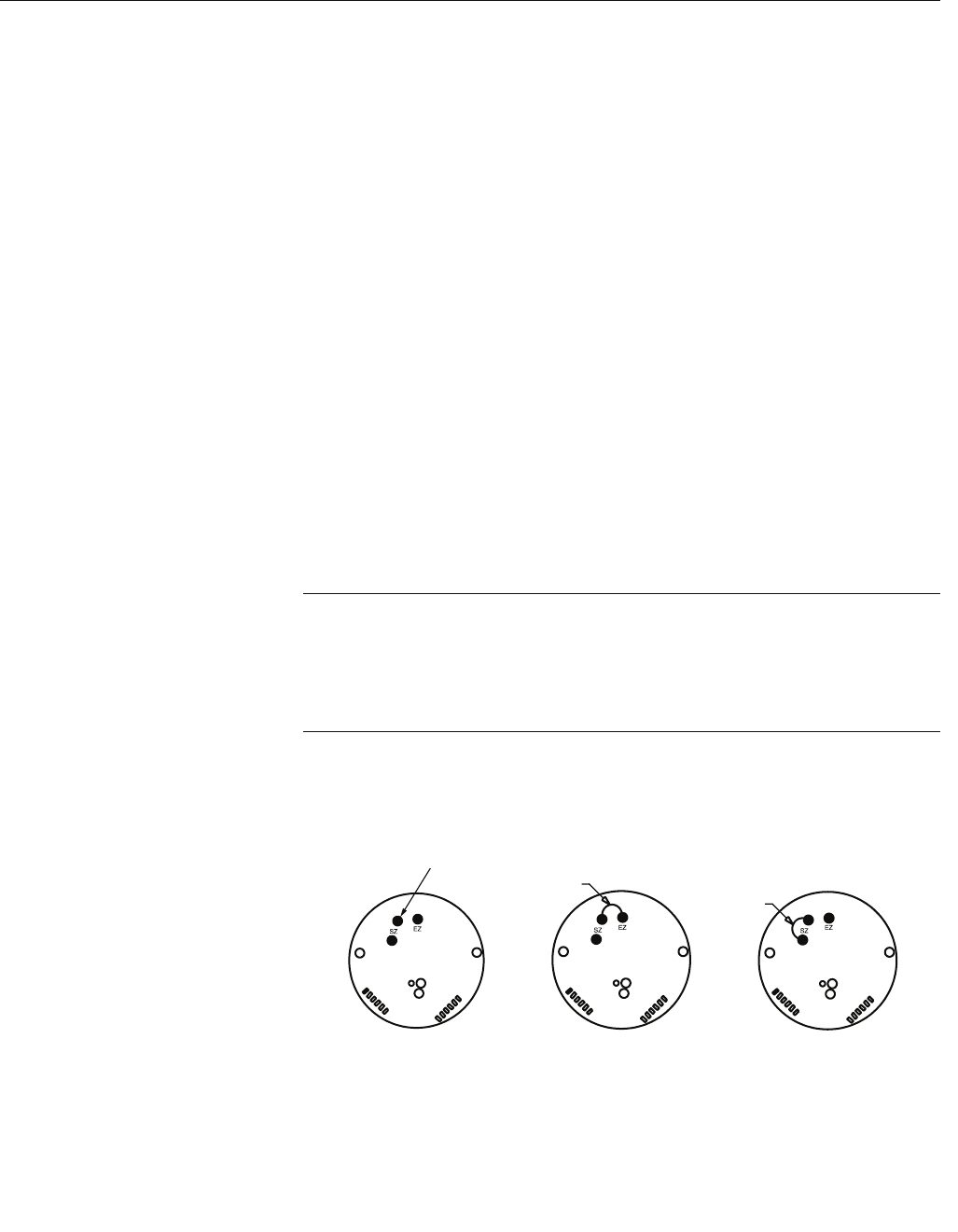

a. Locate the three turret terminals on the component side of the

amplifier board. Remove any jumper wires between them (see

Figure 3-3).

b. To elevate zero, connect a jumper wire between the middle

terminal and the terminal marked “EZ” (see Figure 3-3, Detail B).

c. Wrap the jumper wire once around each terminal and cut off

any excess.

d. Solder the jumper wire to the terminals using proper electronics

soldering techniques. Clean solder joints thoroughly with isopropyl

alcohol.

e. Plug the amplifier board back in and complete the

zero adjustment.

To suppress zero, follow the same procedure, except connect the jumper wire

between the middle terminal and the terminal marked “SZ” (see Figure 3-3,

Detail C).

6. Recheck full scale and zero and fine tune if necessary.

NOTE

There is some mechanical backlash in the zero and span adjustments, so

there is a dead band when you change the direction of adjustment. Because

of the backlash, the simplest procedure, if the desired setting is overshot, is to

intentionally overshoot a larger amount before reversing the direction of the

adjustment.

Figure 3-3. Jumper Wire

Placement.

Linearity Adjustment In addition to the span and zero adjustments, there is a linearity adjustment

located inside the transmitter on the amplifier board (see Figure 3-4 on

page 3-5). Linearity is factory calibrated for optimum performance over the

calibrated range of the instrument and is not normally adjusted in the field. If

you want to maximize linearity over some particular range, use the following

procedure:

DETAIL B

(To Elevate Zero)

DETAIL C

(To Suppress Zero)

DETAIL A

Moderate

Elevation/

Suppression

(No Jumper Wire)

Jumper

Wire

Jumper

Wire