16

sealed with tiny leads protruding

from either end. Refer to figure

10. These leads extend into the

tube and overlap one another

with a separation of a few thou-

sandths of an inch. The leads are

made from a ferrous material that

is influenced by a magnetic field.

They are first plated with gold as a base material, then

with rhodium and finally ruthenium. Ruthenium is the best

contact material known.

The glass assembly is then placed in the center of a

multilayer coil of copper wire. The entire assembly is

molded together in a tough shock absorbing material. The

switch and coil connectors extend from the bottom in the

form of printed circuit board terminals. When a DC volt-

age is applied to the coil, current flows and creates a mag-

netic field. The force of the field causes the leads to bend

and contact one another inside the sealed glass tube. The

inert gas eliminates corrosion of the contacts and insures a

low resistance, distortion free switch.

All inputs, outputs, and data ports are controlled by

logic circuits in the MA7000. The logic is changed by

front panel push-buttons or by a microprocessor IR de-

coder. This microprocessor IR decoder is programmed

with exclusive McIntosh software. It receives data from the

front panel or external sensors and provides the command

signals for input switching, data switching, and volume

control.

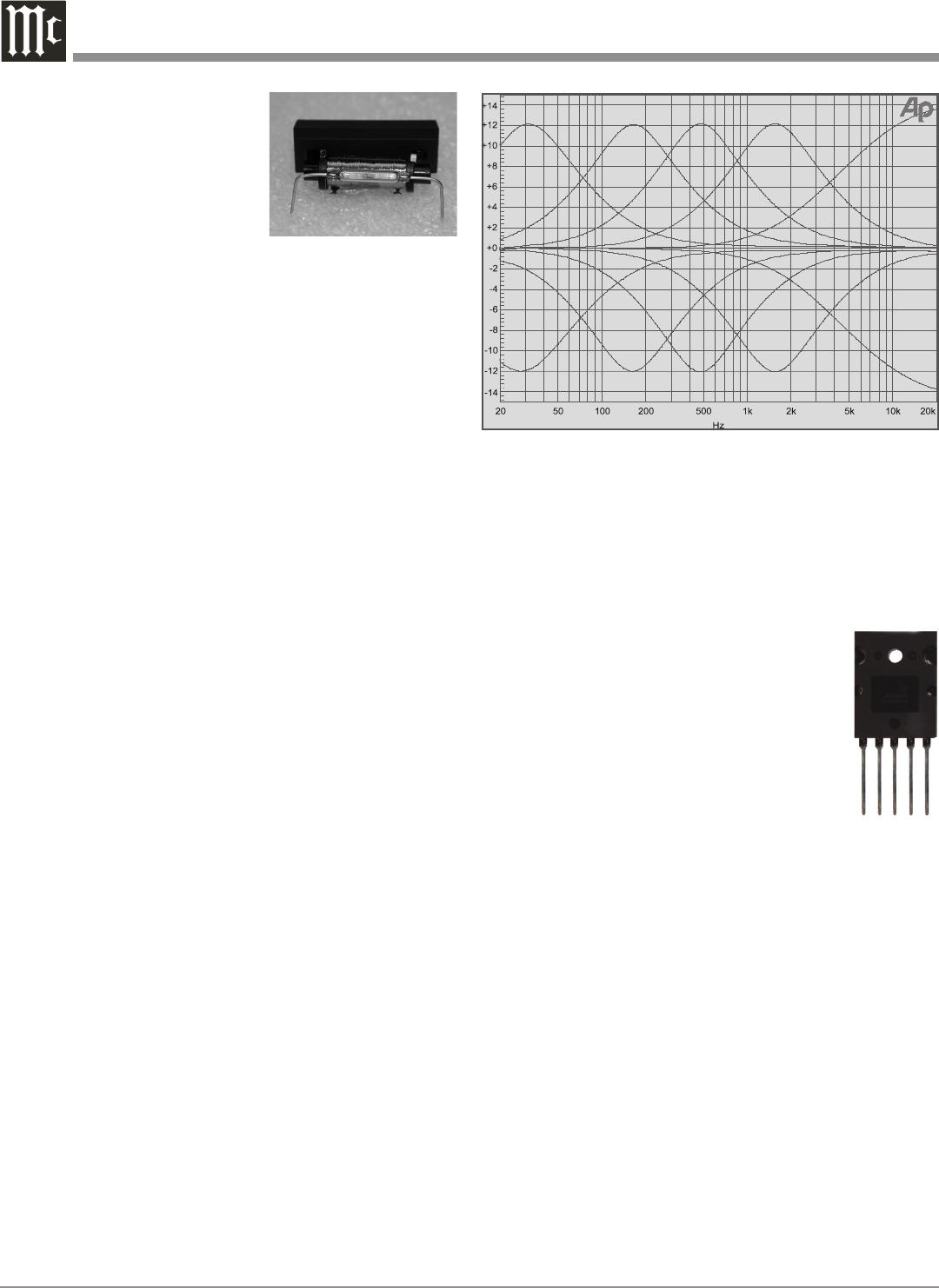

The equalizer section uses several high technology

operational amplifiers. The amplifier stage has been op-

timized for the best transient performance and minimum

distortion. Five other operational amplifiers are arranged

in a circuit configuration that is the equivalent of a series

turned circuit. A control potentiometer inserts this series

tuned circuit into either the feedback or input section of the

equalizer amplifier. This provides a 12dB boost or cut at

the frequency of the tuned circuit. Refer to figure 11. The

overall gain of the stage is 0dB when the potentiometer is

at its center detent position. In this position the tone control

elements are completely removed from the signal path.

Power Amplifier Design Philosophy

The design philosophy incorporated in the MA7000

involved several different techniques, all based on sound

scientific logic. Every stage of voltage or current ampli

-

fication must be as linear as possible prior to the use of

negative feedback. McIntosh engineers know how to prop-

erly design negative feedback circuits so they contribute to

the extremely low distortion performance expected from

a McIntosh Amplifier. The typical McIntosh owner would

never accept the approximately 100 times higher distortion

of many non-feedback designs.

All transistors are selected to have nearly constant cur

-

rent gain over the entire current range they must cover. The

12 Power Transistors used in each channel of the MA7000

Power Output Circuitry, have matched uniform current

gain, high current bandwidth product and a large active

region safe operating area. These Power Transistors are the

very latest in semiconductor technology and

incorporate a new design known as Thermal-

Trak™. Refer to figure 12. This allows for the

instantaneous and accurate monitoring of the

Power Transistor Temperature. The MA7000

Power Output Circuitry has a specially de-

signed bias circuit to take full advantage of

the ThermalTrak™ Power Transistors and thus

precisely controls the power amplifier opera-

tion over a wide range of music conditions

with the benefits of lower distortion and cooler operation.

Precision metal film resistors and low dielectric absorption

film capacitors are used in all critical circuit locations.

The output signal of the circuit is coupled together

in the unique McIntosh MA7000 Output Autoformer.

It provides low distortion power transfer at frequencies

from below 20Hz to well beyond 20,000Hz with optimum

impedance points of two ohms, four ohms and eight ohms.

The unequaled expertise of McIntosh in the design and

manufacturing of autoformers is legendary in the high

fidelity industry.

The high efficiency circuit design of the MA7000 con-

tributes to low operating temperatures. More than 1,000

square inches of heat sink area keep the MA7000 operating

safely with convection cooling. No fans are needed.

Figure 10

Figure 11

Figure 12

ThermalTrak™ - is a trademark of Semiconductor Components Industries,

LLC (SCILLC)