77

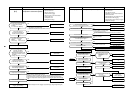

Check code name

[H16]

Check code name

Oil level detective circuit system error

(Auxiliary code : 02)

Cause of operation

1. Detachment of TK2 sensor, miscabling,

characteristics error of resistance value

2. Oil-equalization circuit error

(Check valve, capillary clogging,

strainer clogging)

3. Refrigerant stagnation in compressor

shell

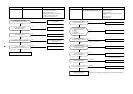

Is not TK2 sensor detached?

Is there no miscabling or misinstallation

on TK1/TK2/TK3/TK4 sensors?

Start a test operation in COOL or HEAT mode.

TK2 sensor temp is displayed on 7-segment display with SW01/02/03=[1] [12] [2].

Check TK2 sensor temp approx. 10 minutes after compressor 2 has operated.

If low temperature continues (approximately outside temp) or temperature

does not almost change, a clogging of strainer of oil-equalization circuit,

clogging of capillary, or malfunction of check valve is considered.

1 Refer to item [H07] error.

2 If OCR operates even after manual reset of OCR, check whether the wiring to the

current sensor (T02) of Comp-IPDU is correct or not.

Outdoor unit temp sensor characteristics-4

Correct miscabling/misinstallation.

TK1: CN514

TK2: CN515

TK3: CN516

TK4: CN523

( )

YES

YES

YES

NO

NO

NO

Check I/F P.C. board

Correct installation of sensor.

Check the clogging of SV3E valve.

(*1)

Are characteristics of TK2 sensor

resistance value normal?

No error

Error

Error

No error

Does OCR of MG-SW operate?

YES

NO

Reset OCR manually.( 2)

Sensor error

Replace clogging part.

Replace SV3E valve.

Strainer

Compressor 2

Oil tank

Capillary tube

TK2

After power reset

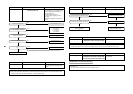

Check code name

[H16]

Check code name

TK3 temperature detective circuit error

(Auxiliary code : 03)

Cause of operation

1. Detachment of TK3 sensor, miscabling,

characteristics error of resistance value

2. Error of SV3C valve circuit periphery

(Check capillary clogging, strainer

clogging)

3. Refrigerant stagnation in compressor

shell

Is not TK3 sensor come off?

Is there no miscabling or misinstallation

on TK1/TK2/TK3/TK4 sensors?

Start a test operation in COOL or HEAT mode.

TK3 sensor temp is displayed on 7-segment display with SW01/02/03=[1] [13] [2].

Check TK3 sensor temp approx. 10 minutes after compressor 2 has operated.

If low temperature continues (approximately outside temp) or temperature

does not almost change, a clogging of parallel capillary is considered.

(Note 1) Refer to item [H07] error.

* Outdoor unit temp sensor characteristics-4

Correct miscabling/misinstallation.

TK1: CN514

TK2: CN515

TK3: CN516

TK4: CN523

( )

YES

YES

YES

NO

NO

NO

Check I/F P.C. board

Correct installation of sensor.

Are characteristics of TK3 sensor

resistance value normal?

Check the clogging of SV3E valve.

(Note 1)

No error

Error

Error

No error

Sensor error Replace

Replace clogged part (Capillary).

Replace SV3E valve.

SV3E valve

Strainer

TK3

After power reset,

check capillary choke of SV3C valve bypass.