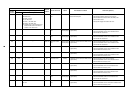

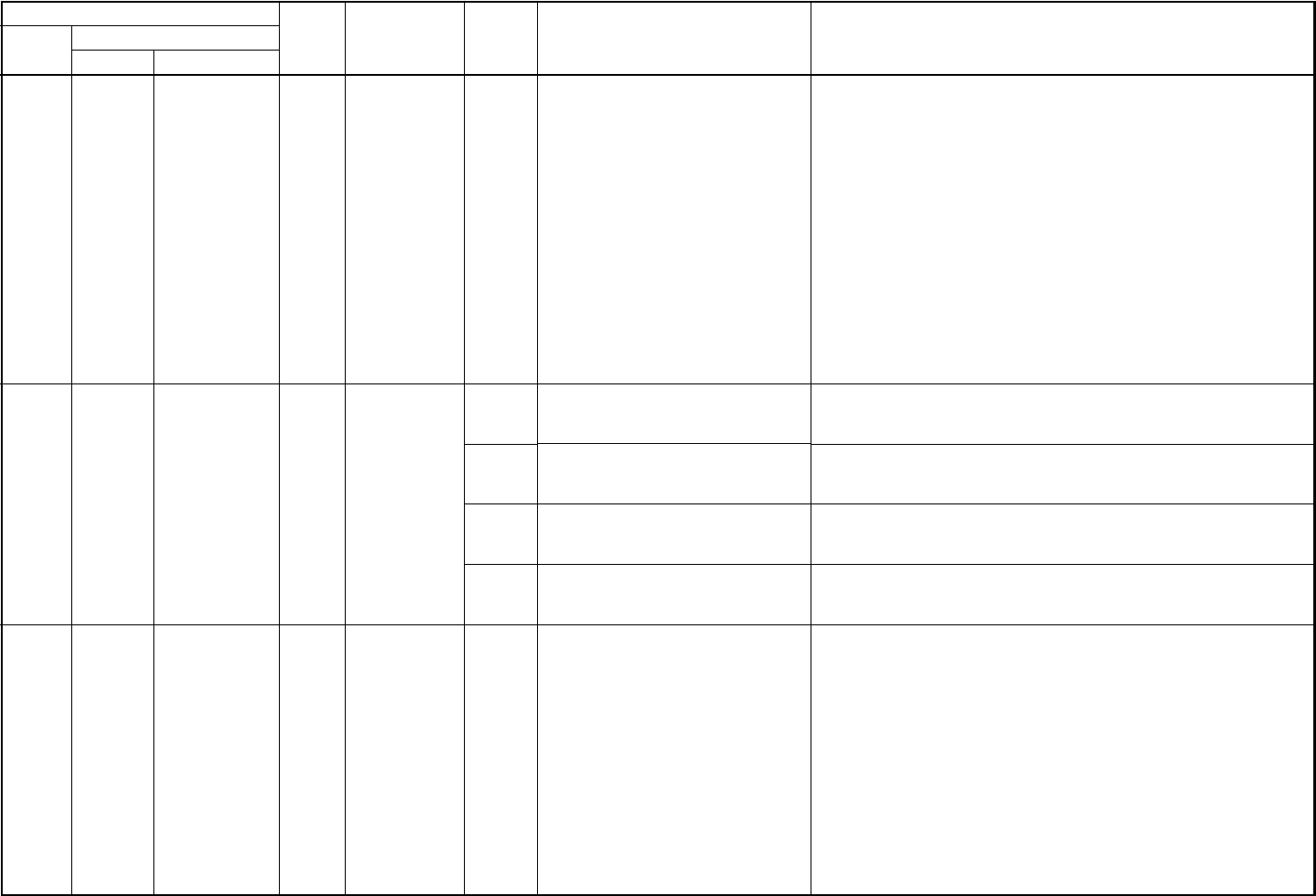

56

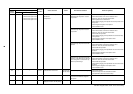

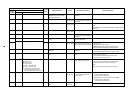

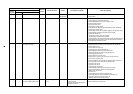

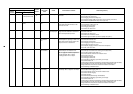

Check code

Main

remote

controller

H07

H08

H14

Outdoor 7-segment display

Check code

H07

H08

H14

Auxiliary code

—

01: TK1 sensor error

02: TK2 sensor error

03: TK3 sensor error

04: TK4 sensor error

—

Detected

position

I/F

I/F

I/F

Check code name

Protection for oil

level drop detection

Oil level detective

temp sensor error

Compressor 2 case

thermo operation

Status

All stop

All stop

All stop

All stop

All stop

All stop

Error detection condition

The operating compressor detected oil shortage

continuously for 2 hours.

• Resistance value of sensor is infinite or zero.

(Open/Short)

• Resistance value of sensor is infinite or zero.

(Open/Short)

• Resistance value of sensor is infinite or zero.

(Open/Short)

• Resistance value of sensor is infinite or zero.

(Open/Short)

Compressor 2 case thermostat operated.

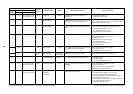

Check item (position)

<Check all the outdoor units in the corresponding line.>

• Check full opening of service valve of balance pipe.

• Check connection and installation of TK1, TK2, TK3, and TK4 sensors.

• Check characteristics of TK1, TK2, TK3, and TK4 resistance values.

• Check gas leak and oil leak in the same line.

• Check refrigerant stagnation in compressor.

• Check error of SV3A, SV3B, SV3C, SV3D, and SV3E valves.

• Check clogging of oil separator oil return circuit.

• Check clogging of oil-equation circuit.

<Check clogging of oil equation pipe between compressors.>

• Check TS1, TS2 sensors (Miswiring and misinstallation of TS1 and TS2)

• Check leakage of SV6 circuit.

• Check FS unit.

Leakage of check valve of bypass between liquid pipe and discharge gas pipe

Mispiping of discharge/suction gas connection

Miswiring of SVD/SVS valve/Misinstallation of coil

• Check whether there is no setup missing of indoor unit in all cooling operation mode

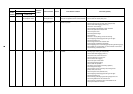

• Check connection of TK1 sensor connector.

• Check characteristics of TK1 sensor resistance value.

• Check outdoor P.C. board (I/F) error.

• Check connection of TK2 sensor connector.

• Check characteristics of TK2 sensor resistance value.

• Check outdoor P.C. board (I/F) error.

• Check connection of TK3 sensor connector.

• Check characteristics of TK3 sensor resistance value.

• Check outdoor P.C. board (I/F) error.

• Check connection of TK4 sensor connector.

• Check characteristics of TK4 sensor resistance value.

• Check outdoor P.C. board (I/F) error.

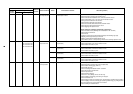

• Check compressor 2 case thermo circuit. (Connector, cable, P.C. board)

• Check full opening of service valve. (Gas and liquid side)

• Check outdoor PMV clogging. (PMV1, 2)

• Check SV42 valve leak.

• Check miscabling/misinstallation of SV41 and SV42.

• Check valve opening of indoor PMV.

• Check 4-way valve error.

• Check refrigerant shortage.

• Check SV11 circuit. (Wiring, OFF at one side only)

• Check mispiping of discharge gas/suction gas main pipe.

• Check Flow selector unit.

Check leakage of SVD valve and SVS valve. (Check leakage of SVDD valve and SVSS.)

Check mispiping of FS unit connecting pipe (Suction gas/Discharge gas), wiring between

FS unit and indoor unit, and connection of connectors.

Check miswiring of SVS/SVD valves.